4 Commissioning

Festo – P.BE-MPA-E N – 1309f – English 97

4.7 Error handling

4.7.1 Impairment of functions

After switching on the compressed air supply or when subsequently testing the individual valves, you

can learn the following about the operating status of the pneumatic system:

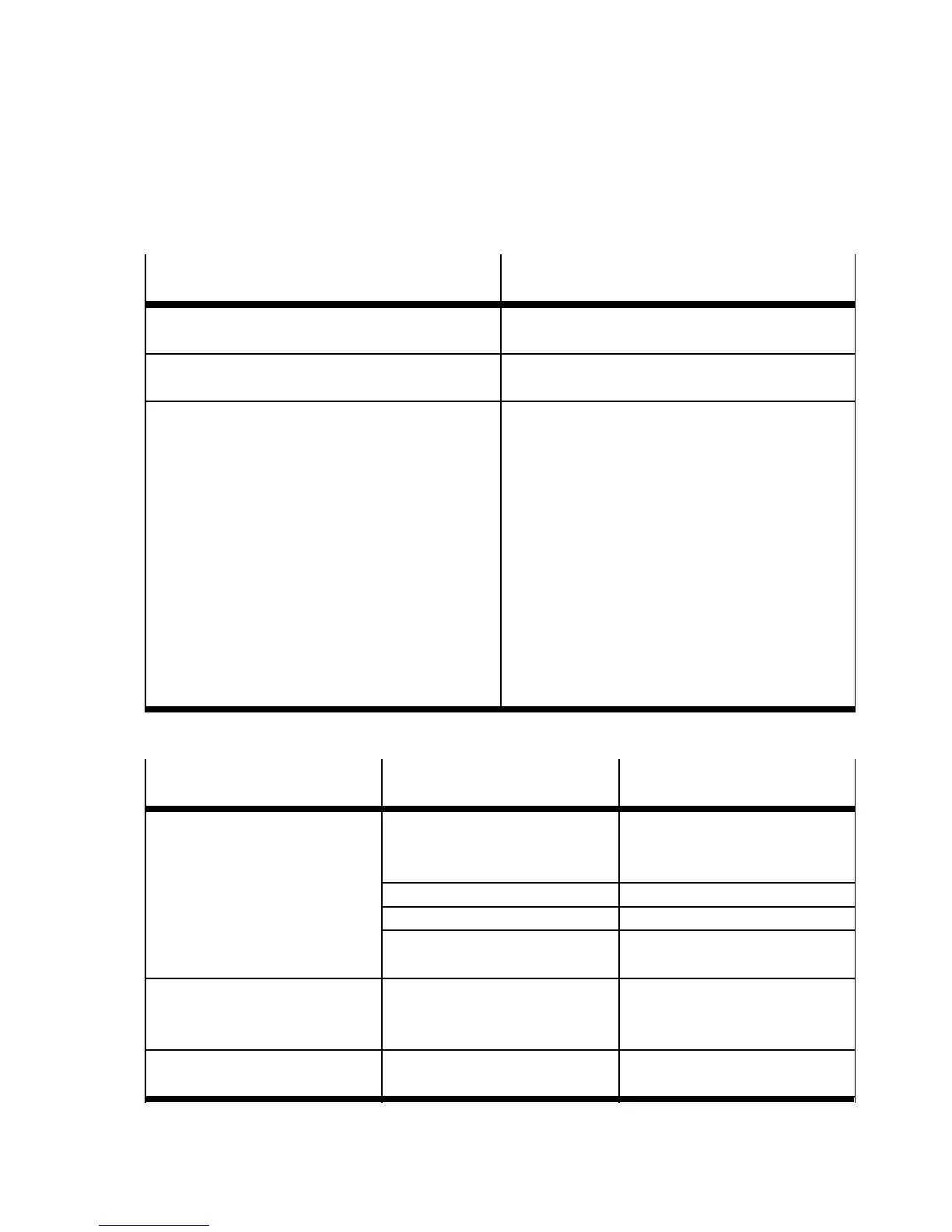

Operating status of the pneumatic system

Error handling when the compressed air supply

has been switched off

Air flows out at common-line or working-line con-

nections

• Check tube assembly

Valve or pneumatic system does not react as ex-

pected

• Check the installation of the tubing lines

• Check the electric cables

Valve or pneumatic system does not react • Bring the detenting manual override into the

initial position

• After switching on again, check the operating

pressure (if necessary for each pressure

zone). Set operating pressure in accordance

with instructions in chapter 3.

• Servicing required

Valve terminals with regulated external pilot air

supply:

• After switching on again, check the pilot

pressure (adjust in accordance with the

operating pressure if necessary, chapter 3

or Appendix A, Fig. A.1 … Fig. A.5)

Tab. 4.9 Function impairment of the pneumatic system

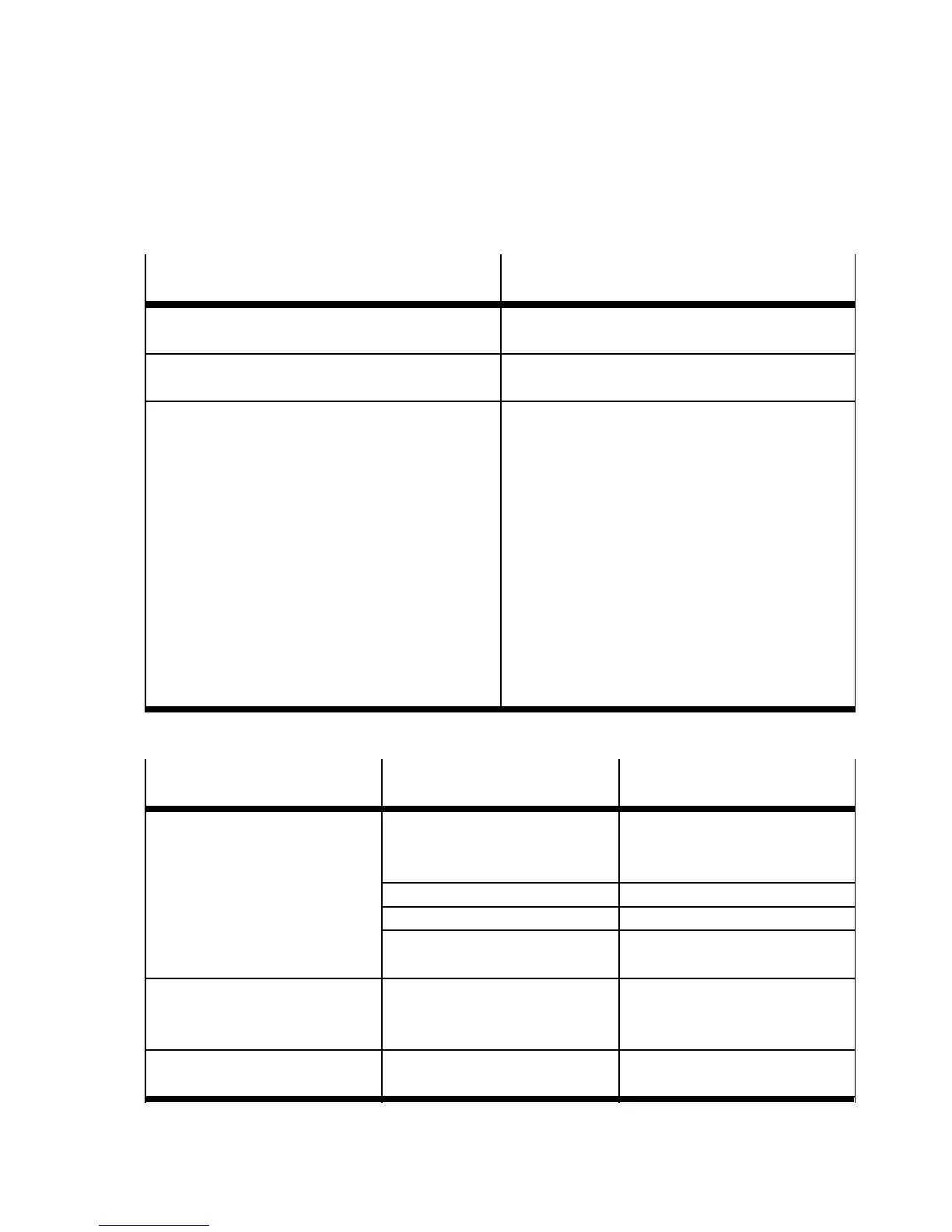

Operating status of the propor-

tional pressure regulator

Possible cause Remedy

Proport io nal pressure regulator

does not react

Supply voltage not applied,

POWER LED or display does not

light up.

• Check the 24 V DC supply

voltage.

No supply pressure • Switch on supply pre ssure.

Setpoint value reached • Modify setpoint v alue.

Proportional pressure regulator

defective

• Send the valve to the Festo

repair service.

Flow rate too low Restriction of the flow cross

section due to connection tech-

nology (swivel fittings)

• Use alternative connections.

Pressure increa se too slow Large cylinder volume and long

tube length

• Select another parameter

record.

Loading...

Loading...