5 Conversion and maintenance

Festo – P.BE-MPA-E N – 1309f – English 101

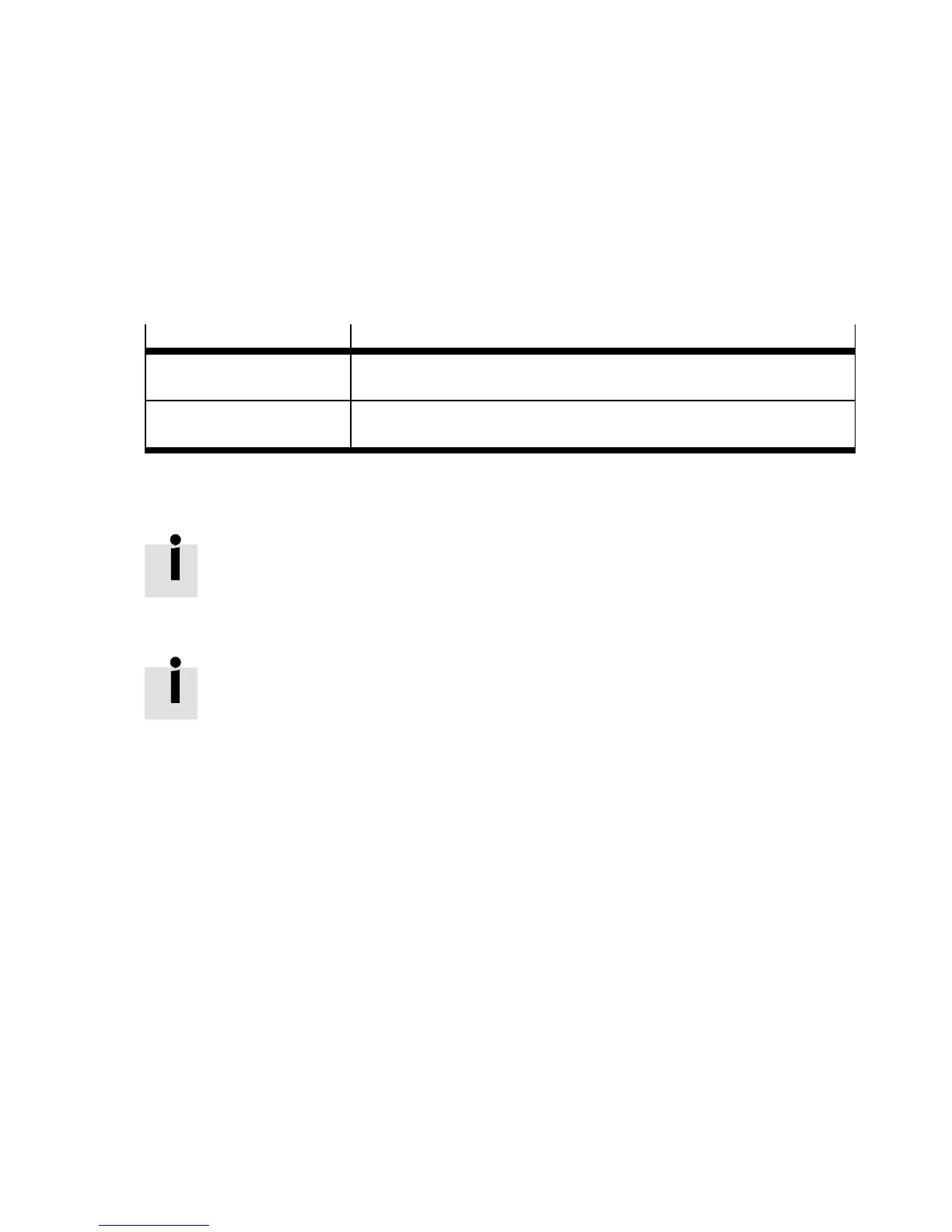

5.2 Dismantling the MPA-S valve terminal

Providing the MPA-S valve terminal is easily accessible, it need not be dismantled when the following

components are replaced or removed:

– Valves or blanking plates

– Electronics module

– Exhaust plates or flat plate silencer.

5.2.1 Disconnect the electrical connections

Alternative connections

Procedure

CPX terminal Information for dismantling the electric connections can be found in

the system description for the CPX terminal.

Multi-pin plug connection • Loosen the mounting screws of the SUB-D multi-pin plug and

remove it.

Tab. 5.1 Disconnect the electrical connections

5.2 .2 Disconnecting the pneumatic connections

Chapter 3 describes how to disconnect t he pneumatic ports.

5.2.3 Dismantling the MPA-S valve terminal

The procedure for dismantling the MPA-S valve terminal is described in cha pter 3.

5.3 Maintenance of the MPA-S valve terminal

5.3.1 Service and maintenance measur es to be executed regularly

Housing and mechanical system

Observe the tightening torque every six months

– of the tie rods

– of all housing screws

– of all mounting screws.

Electrical c omponents

Check every six months

– the tightening torque of the screw of the earthing cable

– the correct seating of all plug connectors

– the tightening torque of the c able connectors (present with some plug connectors).

Loading...

Loading...