4 Commissioning

98 Festo – P.BE-MPA-EN – 1309f – English

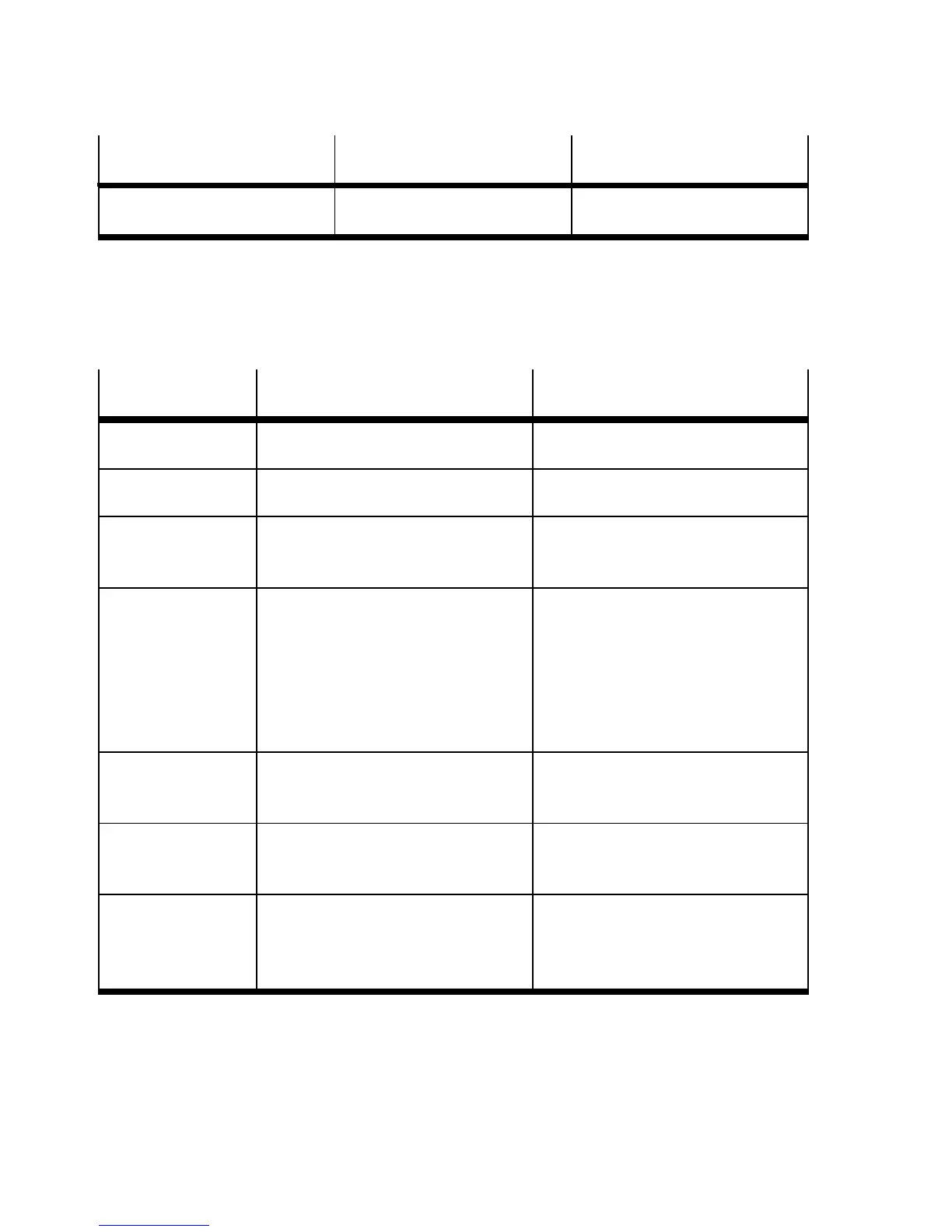

Operating status of the propor-

tional pressure regulator

RemedyPossible cause

Pressure constant despite modi-

fied setpoint specific ation

Too little supply pressure p1 • Increase supply pressure.

Tab. 4.10 Functional impairment of the proportional pressure regulator

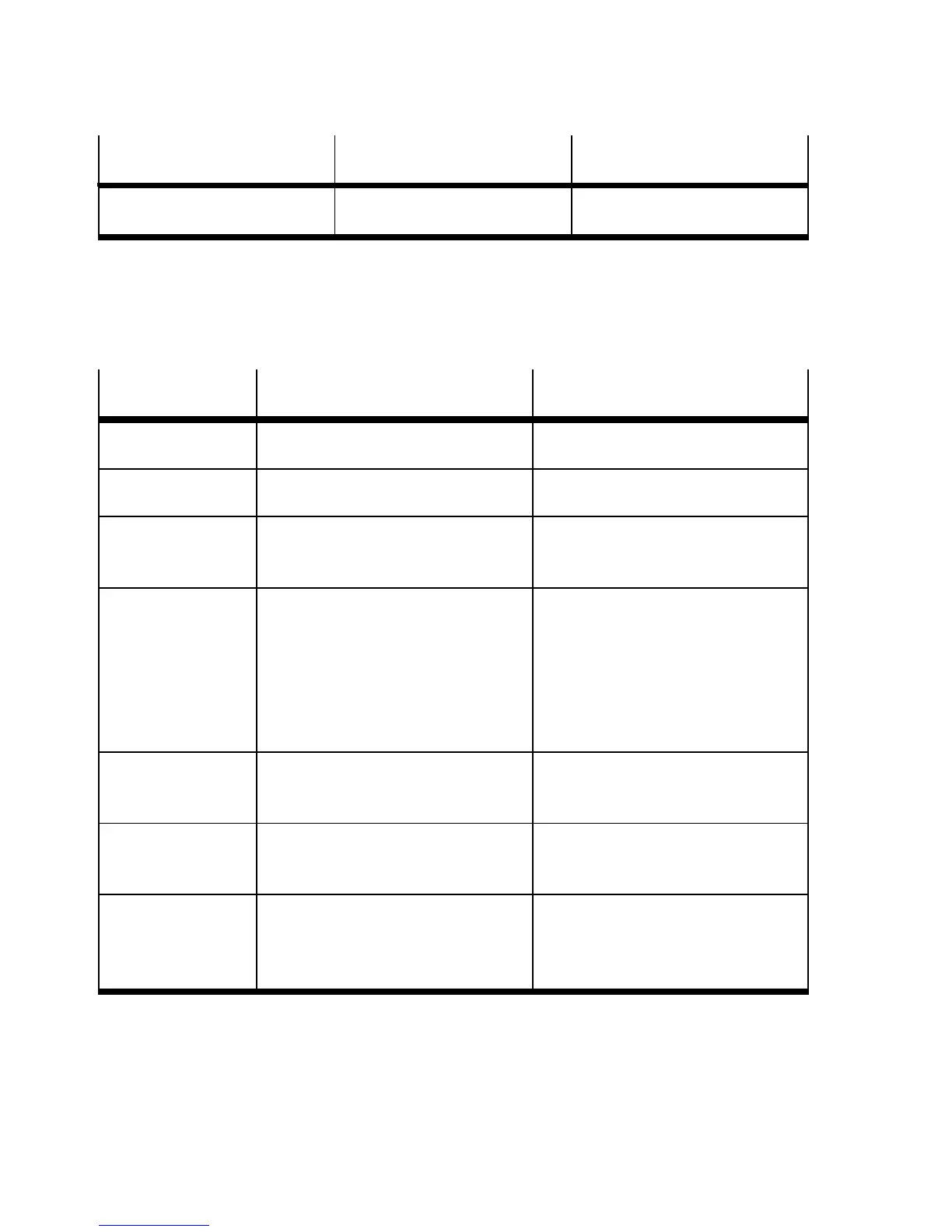

4.7.2 Operating statuses of the pneumatic system

The following requirements should be fulfilled in order to achieve the desired pneumatic operating

statuses listed below:

Desired pneumatic

operating status

Requirement Comment

Zero leakage – Tubing connected with care

– R egulated pilot air supply

—

Fast reaction Suffic ient pressure supply by mea ns

of compressed air supply

ExhausttheMPA-Svalveterminalvia

all exhaust plates.

Trouble-free Non-return valves in common exhaust

line

This applies when several systems

with centrally ducted exhaust air are

used

Two or more

pressure zones

– Limitat ion of the pressure zones

by means of separating seals with

blocked channels

– Corresponding number of

pneumatic air supply plates for

supplying the different pressure

zones

Subsequent conversion possible

( chapter 5)

Vacuum or

low-pressure

operation

Externally supplied regulated pilot air

supply

Vacuum/ low pressure operation not

with 2x 2/2- and 2x 3/2 directional

control valves (ident. code D, I, H, K, N)

EMERGENCY OFF of

pressure zones

Guarantee of the controller function

for the pilot air supply despite the

overall supply being switched off

The controller regulates the pilot air

supply to all valve sub-bases of an

MPA-S valve terminal.

Slow start-up after

EMERGENCY OFF

If control signals are present, the

pilot air supply m ust be at the

required level immediately after

switch-on

—

Tab. 4.11 Pneumatic operating statuses

Loading...

Loading...