5 Conversion and maintenance

124 Festo – P.BE-MPA-EN – 1309f – English

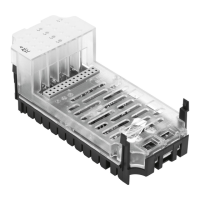

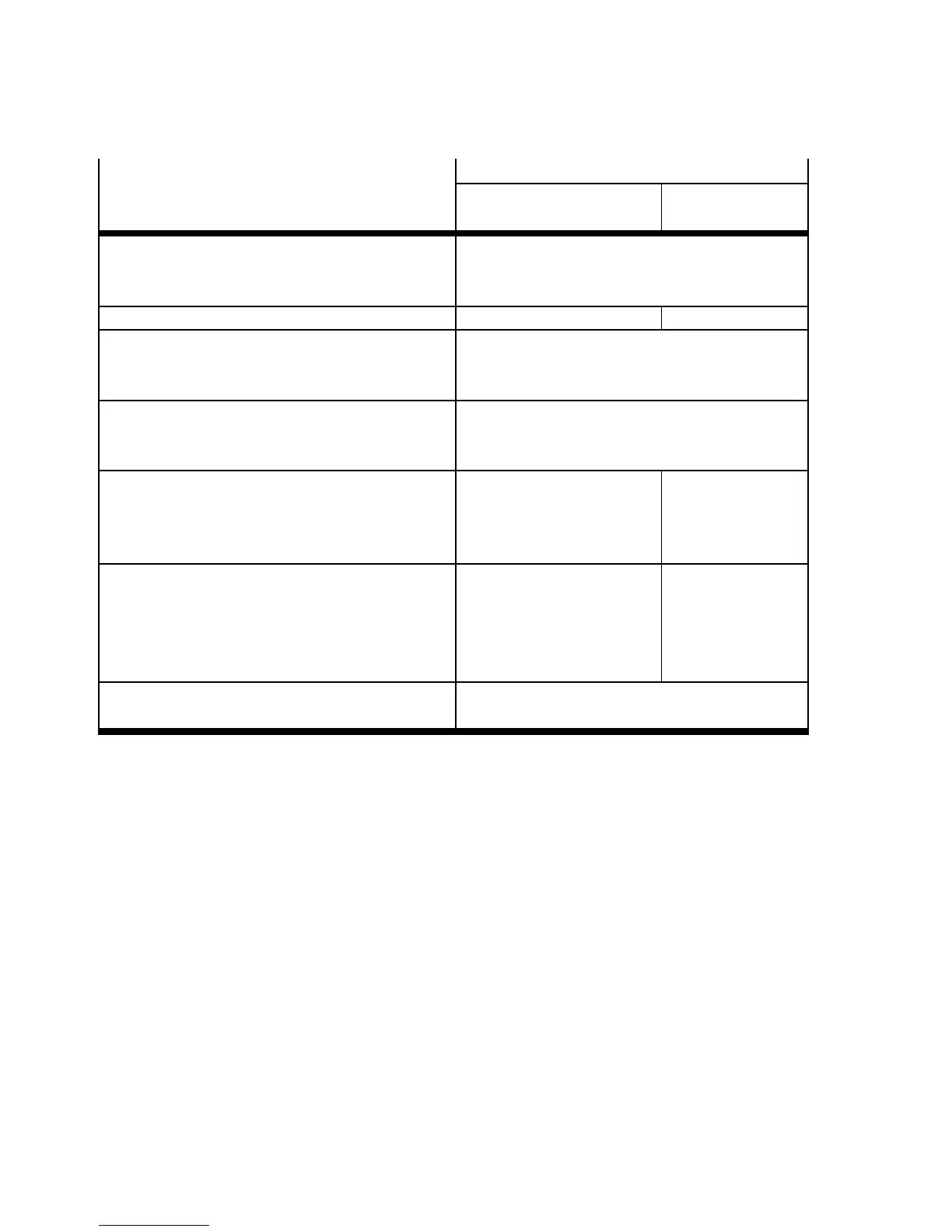

For expansion, you will require the following components:

Components

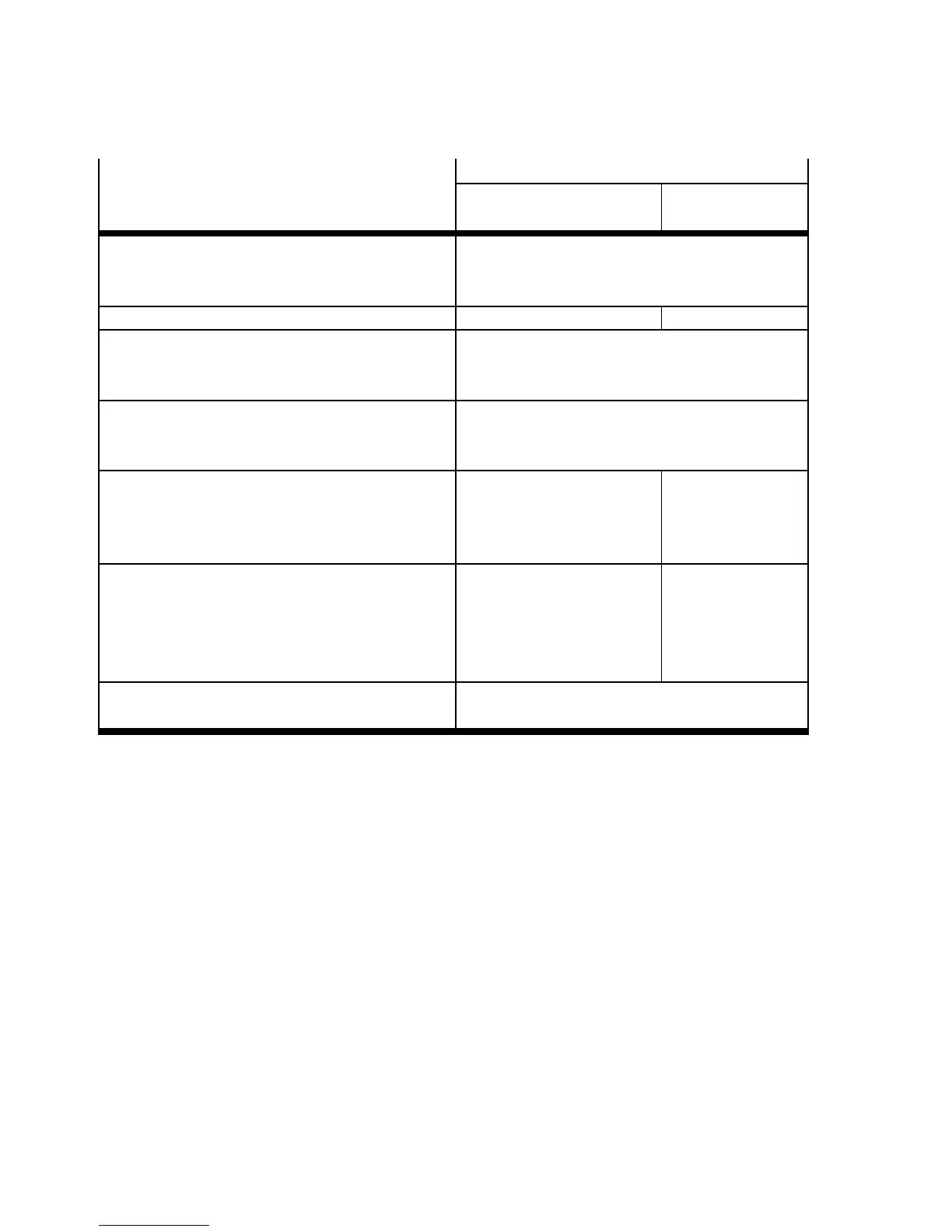

MPA-S valve terminal with ...

CPX terminal Multi-pin plug

connection

One sub-base per:

– MPA1: 4 valve positions VMPA1-FB-AP-4-1

1)

or VMPA1-FB-AP-4-1-…

2)

– MPA2: 2 valve positions VMPA2-FB-AP-2-2

1)

or VMPA2-FB-AP-2-2-…

2)

One electronics module per sub-base Tab. 5.3 Tab. 5.4

Valve or blanking plates:

– MPA1: 4 per sub-base VMPA1-M1H-… or VM PA1-RP

– MPA2: 2 per sub-base VM PA2-M1H-… or VM PA2-RP

Possibly additional pneumatic air supply plate:

– With exhaust plate VMPA…-FB-SP

– With flat plate silencer VMPA …-FB-SPU

If necessary, additional electric supply plate: —

– With plug M18 VMPA -FB-SP-V

– With plug 7/8” (4-pin) VMPA-FB-SP-7/8-V-4POL

– With plug 7/8” (5-pin) VMPA-FB-SP-7/8-V-5POL

For each added sub-base or pneumatic air supply

plate, the corresponding interlinking boards:

– I nterlinking board for sub-base VMPA1-FB-EV-AB Tab. 5.5

– I nterlinking boards for pneuma tic air supply

plate

VMPA1-FB-EV-V

For each added sub-base or pneumatic air supply

plate, the corresponding seal or separating seal

chapter 2, Tab. 2.9

1) Sub-bases without pressure zone separation

2) Sub-bases with pressure zone separation in channel (1) ( also chapter 2, Tab. 2.9).

Tab. 5.10 Valve position extension

Dismantling

Proceed as follows:

1. Loosen the M PA-S valve terminal from the mounting surface ( c hapter 3).

2. Dismantle the sub-base or air supply plate at the point where you wish to extend the terminal

( section 5.3.7).

3. Only MPA-S valve terminal with multi-pin plug connection:

If you wish t o mount a furthe r sub-base to the last sub-base befo re the right MPA end plate, you

mustremovetheendpiecetypeMPAfromthelastinterlinkingboard(.Fig.5.18)

Loading...

Loading...