5 Conversion and maintenance

126 Festo – P.BE-MPA-EN – 1309f – English

Note

Damage to components and malfunctions!

Please note, ...

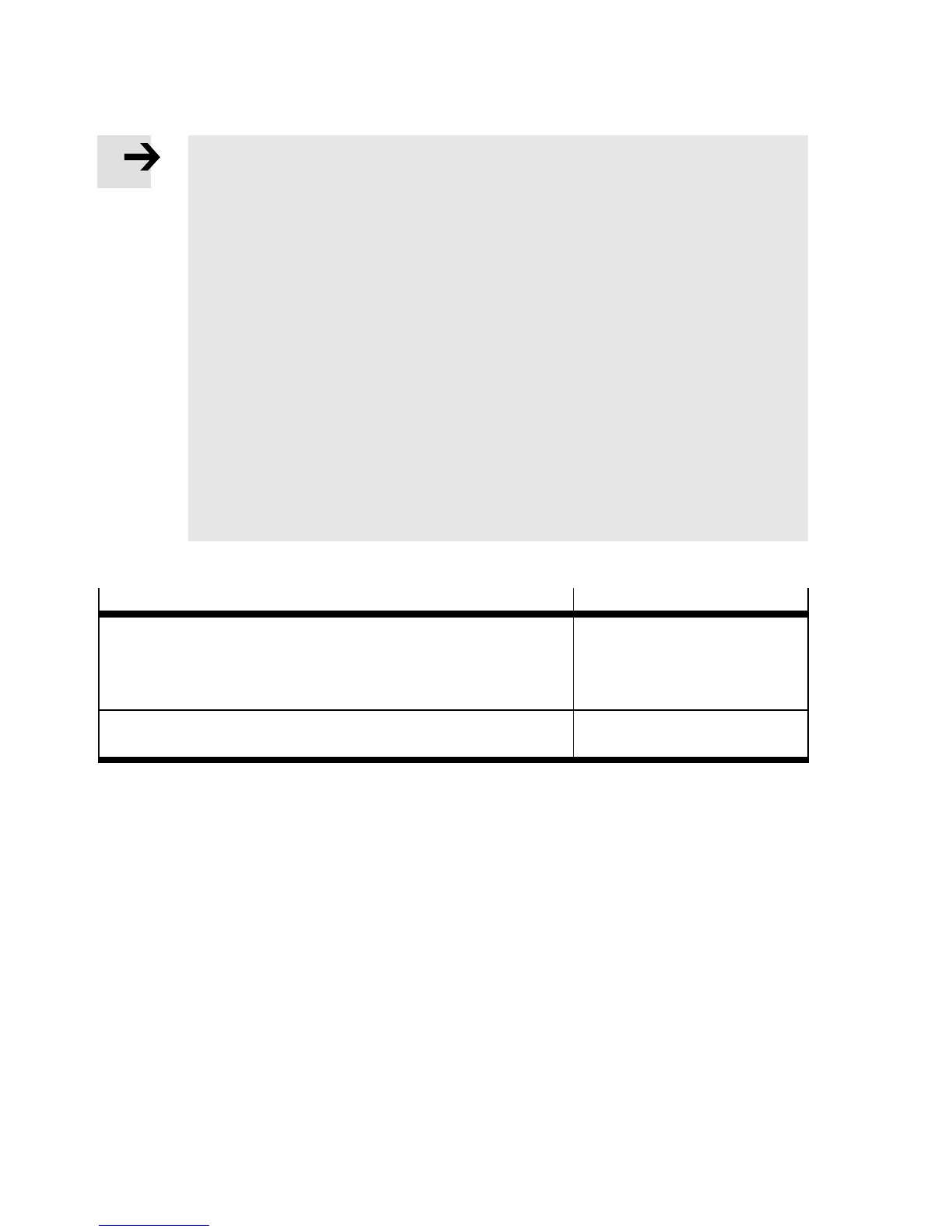

– that with valve terminals of type MPA-S with mo re than 8 sub-bases, an elec tric

supply plate is required for supplemental supply of load voltage.

– that to the right of the electric supply plate, only electronics modules with separated

circuits of type VM PA..-FB-EMG-... are permitted ( also chapter 5.3.6). If your

MPA-S valve terminal is only equipped with electronics modules with a common

circuit (type VMPA...-FB-EMS-...), you can supply the pneumatics as follows:

– for v alve terminals with CPX terminal: exclusively via an interlinking block with

4-pin system supply, type CPX-GE-EV-S or CPX-GE-EV-S-7/8-4POL of the CPX

terminal.

– forvalveterminalswithCPIinterface:throughtheCPIinterfaceoftypeVMPA-CPI.

– that the electric supply plate must not be installed dire ctly to the left of a pneumatic

air supply plate (type VMPA1-FB-SP…).

– that you do not touch the electrostatically sensitive contact surfaces of the plug

connect ors on the side of the electric supply plate.

For expansion you will need:

Components

Type

One of the following MPA electric supply plates

– With plug M18, (3-pin) VMPA-FB-S P-V

– With plug 7/8” (4-pin) VMPA-FB-SP-7/8-V-4POL

– With plug 7/8” (5-pin) VMPA-FB-SP-7/8-V-5POL

Also, a seal without channel separation or a separating seal with

channel separation

chapter 2, Tab. 2.9

Tab. 5.11 Electric supply plates

Mounting

Proceed as follows:

1. Loosen the electric and pneumatic c onnections and then remove the M PA-S valve terminal from its

mounting surface ( chapter 3).

2. Mount the electric supply plate as desc ribed in the VMPA-FB-SP-...-V-... assembly instructions.

3. Mount the MPA-S valve terminal onto the mounting surface ( chapter 3, “Wall mounting” or

“H-rail mounting”).

4. Then install the pneumatic and electrical connections ( chapter 3).

Loading...

Loading...