SECTION 4 – SYSTEM INSTALLATION

UL / ULC Ex4623 Fike Clean Agent System w/ FM-200™ Page 11 of 21

FM 3010715 Manual P/N: 06-215 (Rev G) Revision Date: January, 2010

4.4 PIPING AND FITTING MATERIALS

Piping materials must conform to the requirements as outlined in NFPA 2001, latest edition. The thickness of the

piping wall shall be calculated in accordance with ASME B31.1 Power Piping Code based on a minimum piping

design pressure of 500 psig (34.4 bar) at 70°F (21°C).

CAUTION: Cast iron pipe, steel pipe conforming to ASTM A120, or nonmetallic pipe shall not be used.

The following piping materials and configurations are acceptable:

Schedule 40 Threaded

Schedule 40 Welded

Schedule 40 Grooved

Schedule 80 Threaded

Schedule 80 Welded

The following piping types and grades are acceptable for pipe configurations utilizing threaded, welded or grooved

end connections:

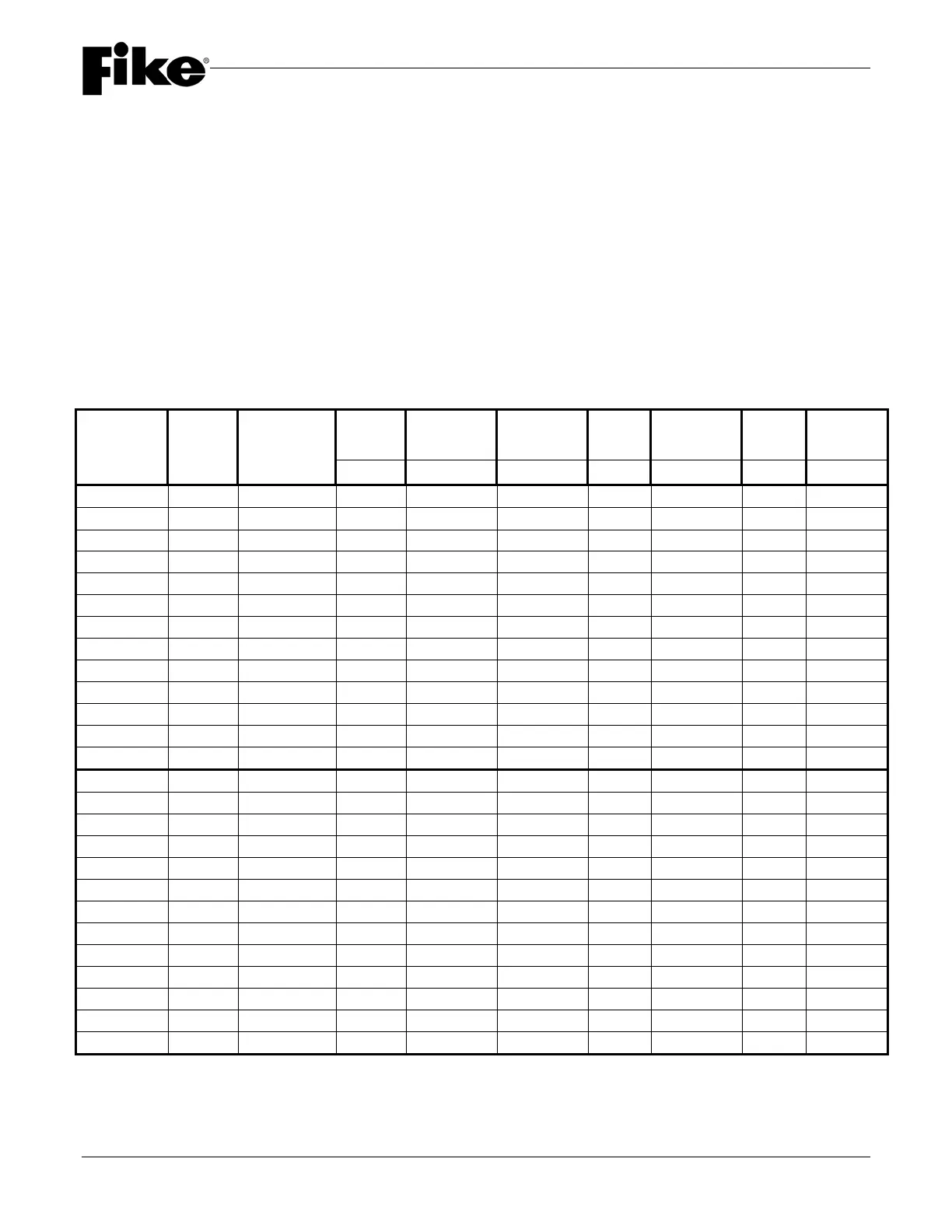

NPS A-53B A-53A

Pipe Pipe Wall Grade: A-106C A-106B A-53B A-106A A-53A A-53F

Schedule Size Thickness Type: Seamless Seamless ERW Seamless ERW Furnace

40 3/8 .091 X X X X X X

1/2 .109 X X X X X X

3/4 .113 X X X X X X

1 .133 X X X X X X

1-1/4 .140 X X X X X X

1-1/2 .145 X X X X X X

2 .154 X X X X X X

2-1/2 .203 X X X X X X

3 .216 X X X X X X

4 .237 X X X X X X

5 .258 X X X X X X

6 .280 X X X X X X

8 .322 X X X X X -

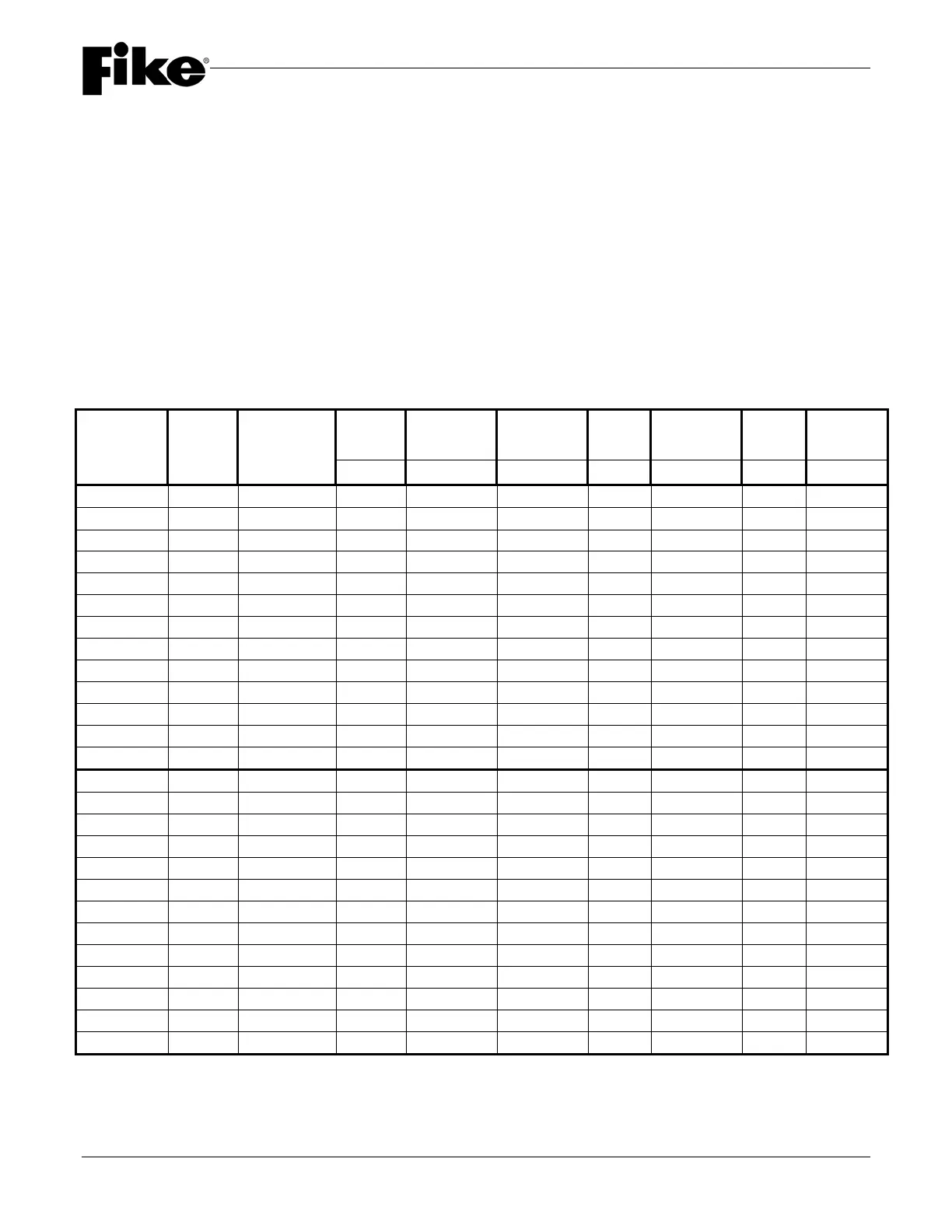

80 3/8 .126 X X X X X X

1/2 .147 X X X X X X

3/4 .154 X X X X X X

1 .179 X X X X X X

1-1/4 .191 X X X X X X

1-1/2 .200 X X X X X X

2 .218 X X X X X X

2-1/2 .276 X X X X X X

3 .300 X X X X X X

4 .337 X X X X X X

5 .375 X X X X X X

6 .432 X X X X X X

8 .500 X X X X X X

Loading...

Loading...