SECTION 2 – DESIGN

Page 24 of 39 Fike Clean Agent System w/ FM-200™ UL / ULC Ex4623

Revision Date: January, 2010 Manual P/N: 06-215 (Rev G) FM 3010715

2.9 ENGINEERED SYSTEM DESIGN LIMITS

The Fike Engineered HFC-227ea System has been tested to define the limitations necessary to accurately predict

how the system will perform when discharged. The physical limitations covered previously (e.g. tee orientation,

flow rate, etc.) are easily seen and managed prior to running a flow calculation. However, the following is a list of

physical limitations that are not easily identified until the system designer runs the flow calculation.

2.9.1 PERCENT OF AGENT IN PIPE

Fike HFC-227ea Systems are pressurized systems that utilize a limited source of pressurization (nitrogen) to

expel the extinguishing agent through the piping network and into the protected space. Therefore, there has to be

a limit placed on the size (volume) of the associated piping network to ensure that the agent will be delivered to

the protected space within the ten (10) second time period allowed. This is a “floating” limitation depends upon

the size and fill weight of the container(s) involved. This makes this a difficult design limitation to identify, but it is

usually associated with very large pipe systems and multiple tee split arrangements.

Therefore, this limitation is defined as follows: no more than 70% of the total agent weight (liquid) may reside in

the piping network during discharge. If the piping volume is too large, the Flow Calculation Program will indicate

an error message, [Percent of Agent Greater Than 70%]. The piping network volume must be decreased by

reducing pipe sizes, reducing pipe lengths, or a combination of both to correct this error.

2.9.2 LOCATION OF FIRST TEE

Some piping configurations present timing problems for the system due to the degree of hydraulic imbalance

created. For example, a system that splits and supplies agent for the room nozzles and underfloor nozzles is

unbalanced because of the difference in pipe size and agent quantities. Therefore, the Flow Program must try to

manipulate the orifice hole diameters of the nozzles in an attempt to satisfy all of the timing requirements for the

system. When the timing criteria cannot be met, the location of the first tee becomes critical.

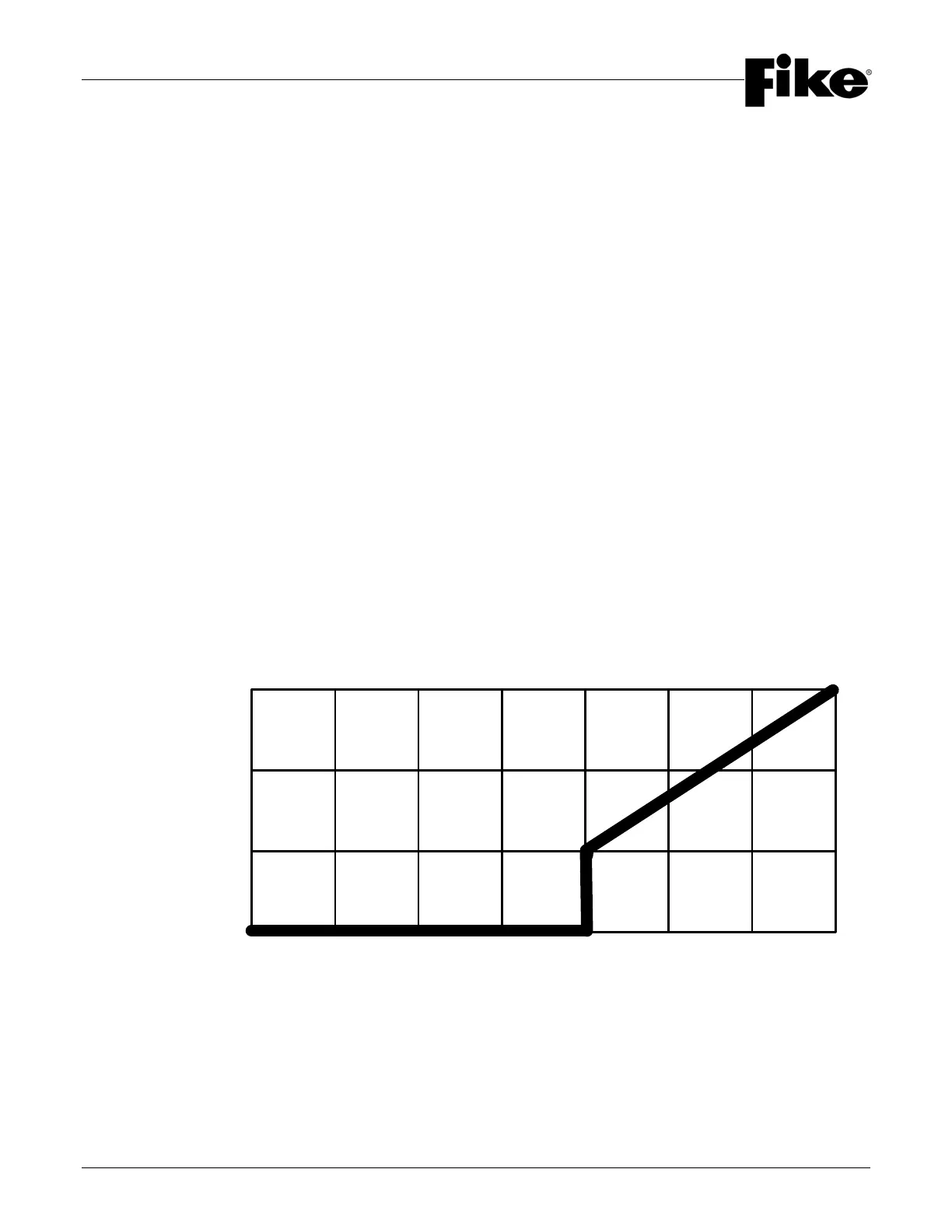

The distance from the cylinder to the first tee depends on the size and configuration of the piping system. The

distance will vary from system to system, so no exact value can be established that is appropriate for all cases. If

the Flow Program determines that the percent of agent in pipe value is 39% or less, no restrictions regarding the

location of the first tee apply. If the percent of agent in pipe value is 40% or higher, the first tee must be located

far enough downstream (away from the container) for a minimum of 10 to 30% of that value to be located in the

piping before the first tee.

Total Percent of Agent in Pipe

0% 10% 20% 30% 40% 50% 60% 70%

0%

10%

20%

30%

Minimum Percent

of Agent in Pipe

Before First Tee

Loading...

Loading...