SECTION 6 – SYSTEM MAINTENANCE

UL / ULC Ex4623 Fike Clean Agent System w/ FM-200™ Page 1 of 3

FM 3010715 Manual P/N: 06-215 (Rev G) Revision Date: January, 2010

The following maintenance procedures and intervals indicated are meant to represent the minimum requirements

for Fike Clean Agent Fire Suppression systems. These procedures do not preclude those required by NFPA

2001 and the authority having jurisdiction. More frequent service intervals may be necessary if systems are

installed in more severe service applications. This section does not cover maintenance and service procedures

for the electrical and control portions of the system. Consult the appropriate product manuals for those products.

6.1 DISCHARGE PIPING

Every six months:

Check the system discharge piping for corrosion and damage. Check all piping supports to make sure they are

tight and all piping is securely supported.

Every year:

Same as six month inspection. The piping should also be blown out with compressed air or nitrogen to check for

obstructions.

6.2 DISCHARGE NOZZLES

Every six months:

Check to see that nozzle orifices are clear and unobstructed, and verify that the orifices are not showing signs of

corrosion.

Make sure the nozzles are aimed or positioned correctly. Verify that the correct nozzle part number is installed at

the proper location in accordance with the system plans.

6.3 AGENT STORAGE CONTAINERS

Every three months:

Check the pressure gauge on each container. The nominal pressure should be 360 PSIG at 70

o

F (24.8 bar @

21

o

C); however, the pressure will vary with temperature. In the range of 50°F to 80°F (10

o

C to 27

o

C) the

difference is approximately 2 psig (15 kPa) per degree. If the pressure loss indicated exceeds ten percent of the

nominal pressure, check the container for leaks and repair as necessary.

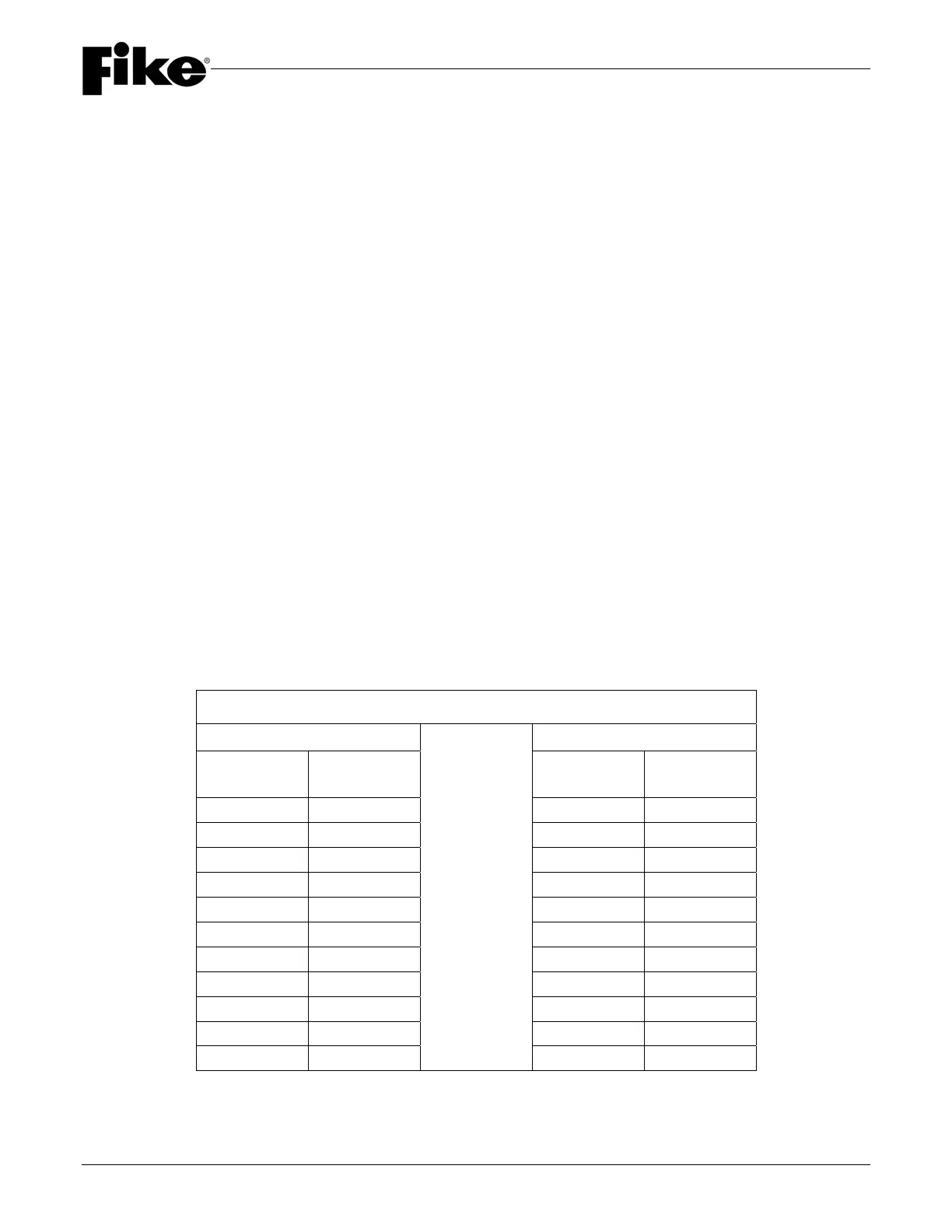

CONTAINER PRESSURE VS. TEMPERATURE

US Standard Metric

Temp.

(

o

F)

Pressure

(psig)

Temp.

(

o

C)

Pressure

(bar)

32 288 0 19.9

40 303 4 20.9

50 321 10 22.1

60 340 16 23.4

70 360 21 24.8

80 381 27 26.2

90 402 32 27.7

100 425 38 29.3

110 449 43 31.0

120 475 49 32.8

130 502 54 34.6

Loading...

Loading...