SECTION 1 – EQUIPMENT

Page 22 of 25 Fike Clean Agent System w/ FM-200™ UL / ULC Ex4623

Revision Date: January, 2010 Manual P/N: 06-215 (Rev G) FM 3010715

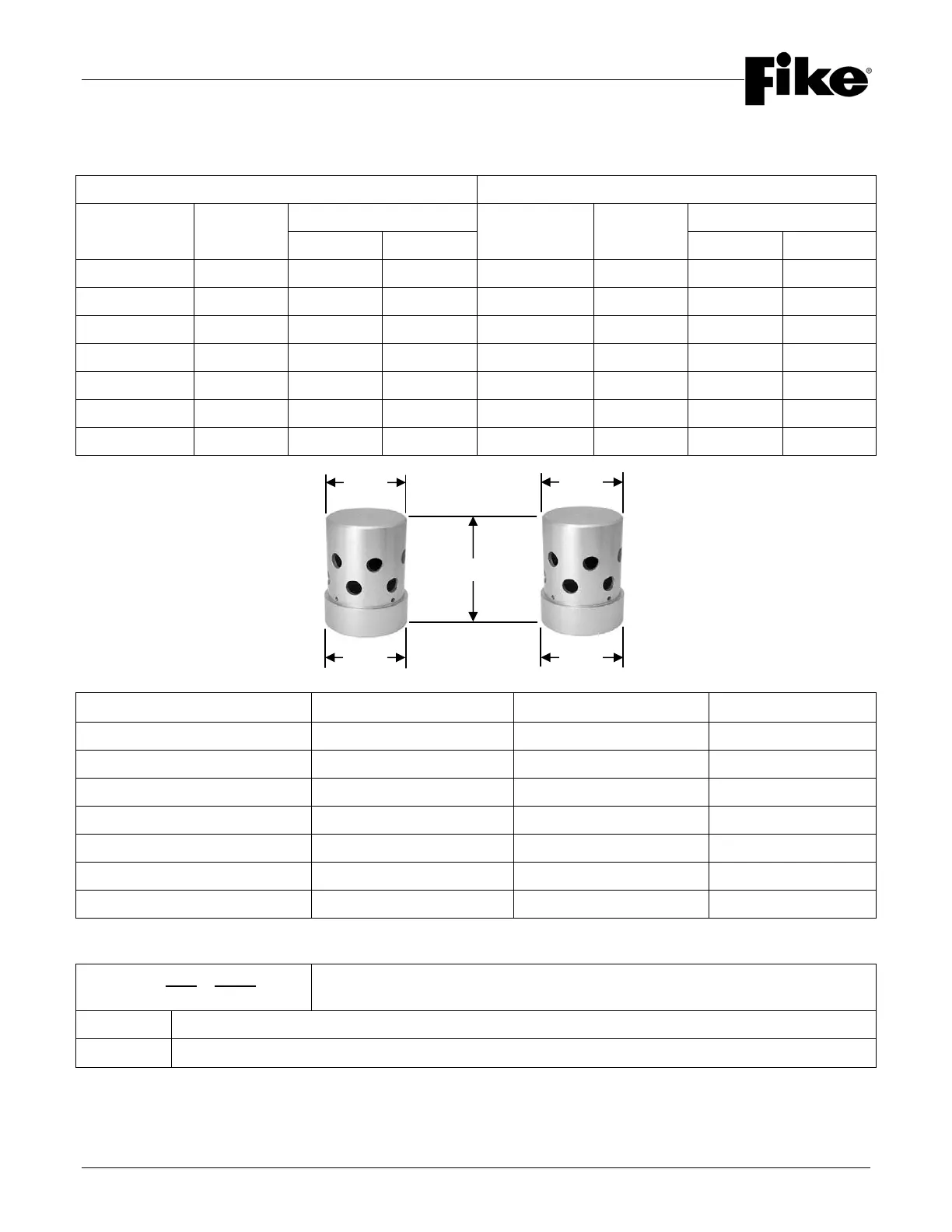

1.10.2 ENGINEERED DISCHARGE NOZZLES

Engineered Discharge Nozzles are available in seven sizes. Nozzle orifice hole diameters are determined by the

Fike Engineered Flow Calculation Program.…….. .

360

o

Engineered Nozzles (12 Orifices) 180

o

Engineered Nozzles (11 Orifices)

Orifice Area (in

2

) Orifice Area (in

2

)

Part Number

Nozzle

Size

(in.-mm)

Minimum Maximum

Part Number

Nozzle

Size

(in.-mm)

Minimum Maximum

80-052-XXXX 3/8 (10) 0.0423 0.1473 80-060-XXXX 3/8 (10) 0.0388 0.1427

80-053-XXXX 1/2 (15) 0.0618 0.2383 80-061-XXXX 1/2 (15) 0.0639 0.2381

80-054-XXXX 3/4 (20) 0.1069 0.4117 80-062-XXXX 3/4 (20) 0.1103 0.4220

80-055-XXXX 1” (25) 0.1743 0.6669 80-063-XXXX 1” (25) 0.1791 0.6831

80-056-XXXX 1 1/4 (32) 0.3054 1.1414 80-064-XXXX 1 1/4 (32) 0.3037 1.1700

80-057-XXXX 1 1/2” (40) 0.4117 1.6076 80-065-XXXX 1 1/2” (40) 0.4136 1.5378

80-058-XXXX 2 (50) 0.6973 2.6594 80-066-XXXX 2 (50) 0.6831 2.5840

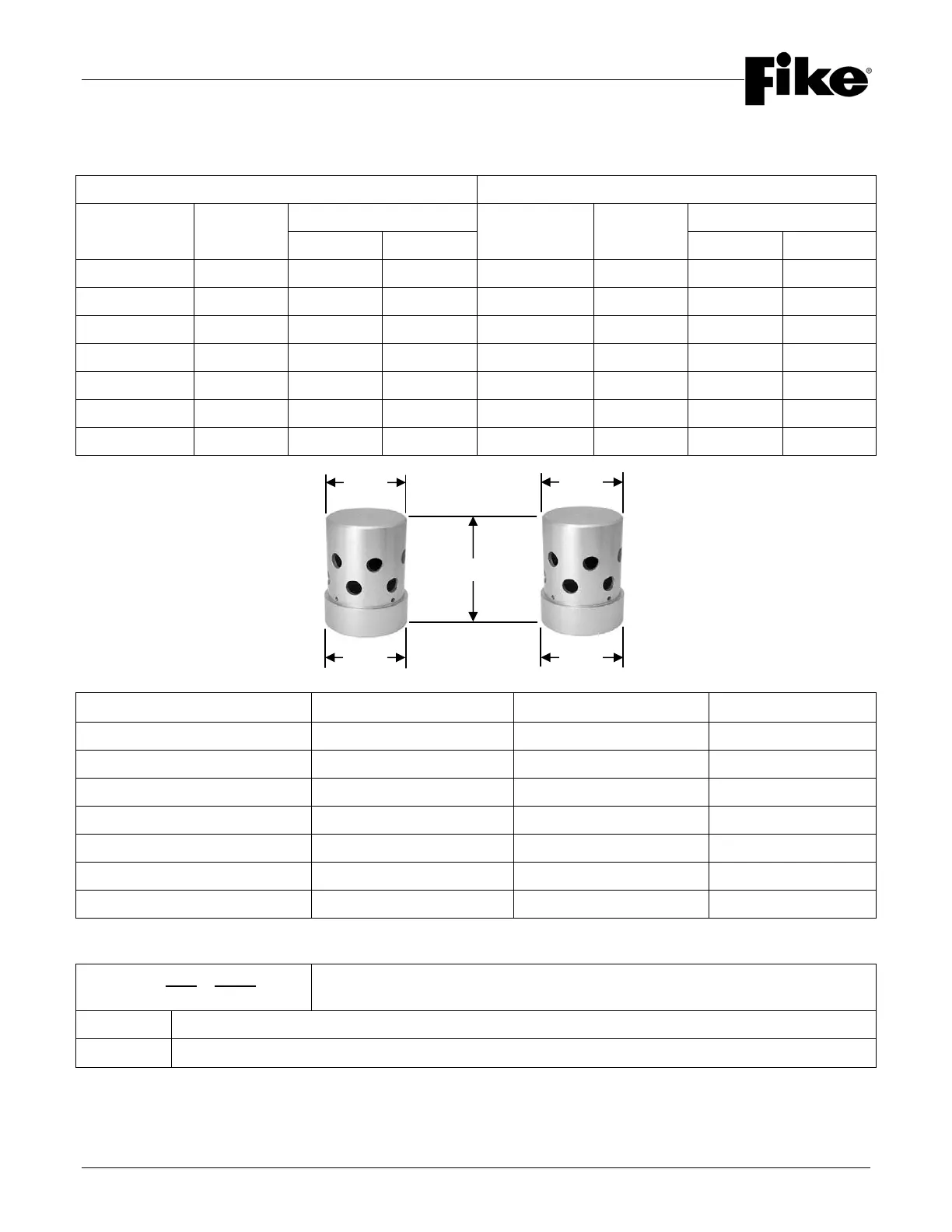

Nozzle Size (NPT-mm)

“A” (in.-mm)

“B” (in.-mm) “C” (in.-mm)

3/8 (10) 1.25 (32) 1.56 (40) 0.87 (22)

1/2 (15) 1.25 (32) 1.88 (48) 1.00 (25)

3/4 (20) 1.75 (44) 2.19 (56) 1.22 (31)

1 (25) 1.75 (44) 2.50 (64) 1.44 (37)

1-1/4 (32) 2.75 (70) 3.13 (79) 1.80 (47)

1 1/2 (40) 2.75 (70) 3.38 (86) 2.02 (51)

2 (50) 2.75 (70) 3.75 (95) 2.50 (64)

1.10.3 NOZZLE ORDERING FORMAT

80 – XXX – XXXX

A B

Orifice hole diameter MUST be specified in addition to the basic part number

for the nozzle needed.

A =

Basic nozzle part number (e.g., 80-038 etc.)

B =

Orifice hole diameter (obtained from Engineered Flow Calculation Program)

“A”

“A”

“C”

“

”

“C”

Loading...

Loading...