SECTION 4 – SYSTEM INSTALLATION

UL / ULC Ex4623 Fike Clean Agent System w/ FM-200™ Page 7 of 21

FM 3010715 Manual P/N: 06-215 (Rev G) Revision Date: January, 2010

4.2 DISCHARGE PIPING CONNECTIONS

The discharge piping is connected to the discharge valves in the various manners that follow. A basic installation

would involve direct connection to the valve via a pipe union or grooved coupling to facilitate removal of the

container for service purposes. More advanced installations will be accomplished by using a discharge manifold

to join multiple containers into a common piping supply network.

Refer to the sections that follow for additional information regarding pipe and fitting materials, installation

requirements, configurations, etc.

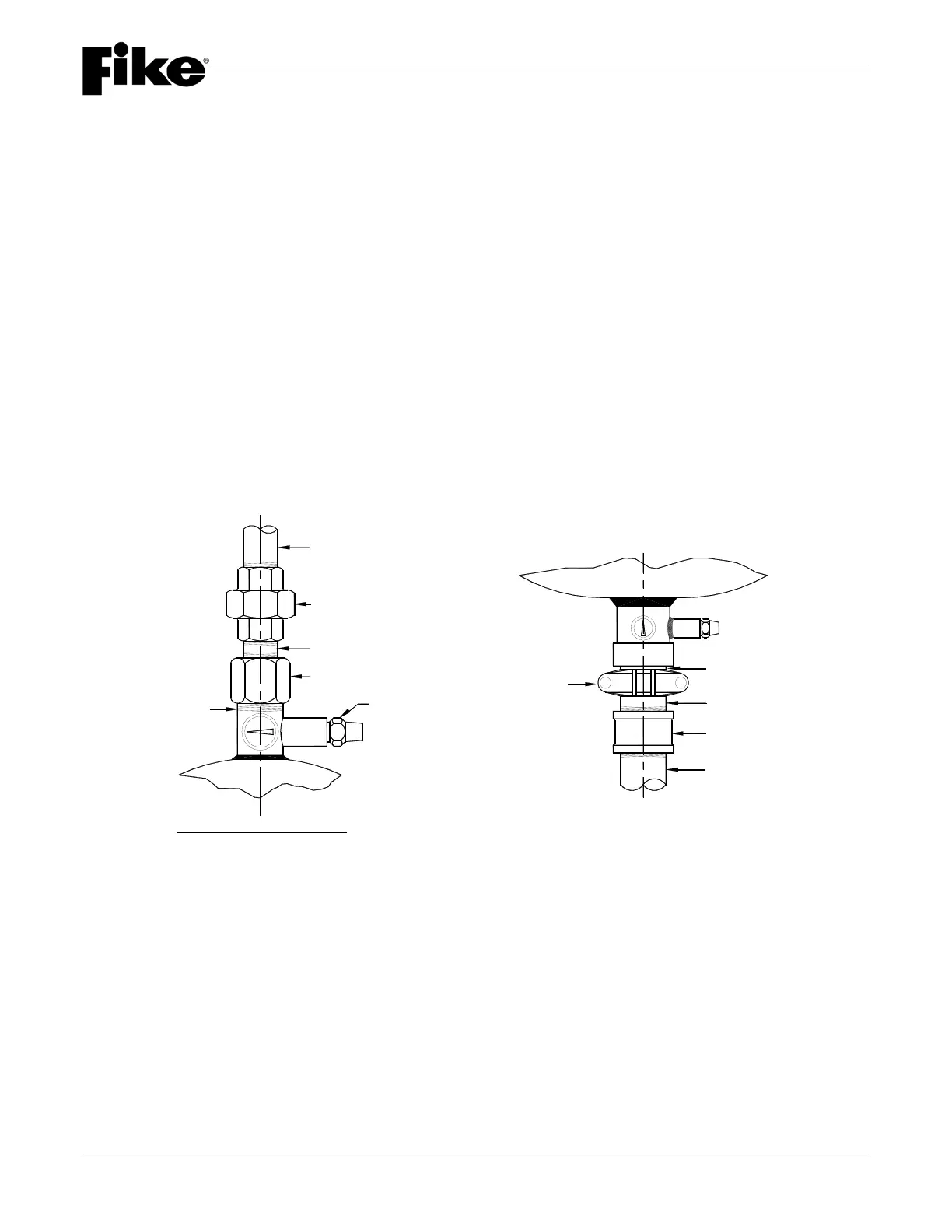

4.2.1 1" (25 mm) VALVE CONNECTIONS

The 1" (25 mm) valve used on the 20, 35, 60 & 100 lb. (8, 15, 27 and 44 L) containers has an Adapter Nut with 1”

NPT female threads that accept 1" NPT male threaded pipe. Prior to installing the discharge piping, remove the

Adapter Nut and coat the 2” (50 mm) straight threads of the container valve body with teflon tape or thread

sealant and replace the Adapter Nut.

IMPORTANT: Remove the Baffle Plug before installing the discharge piping to the Adapter Nut. The Baffle Plug

is an anti-recoil device that is required to be installed whenever transporting or handling charged

containers that are not connected to the discharge piping.

A pipe union should be installed close to the adapter nut. This makes removal of the container for service

purposes much easier.

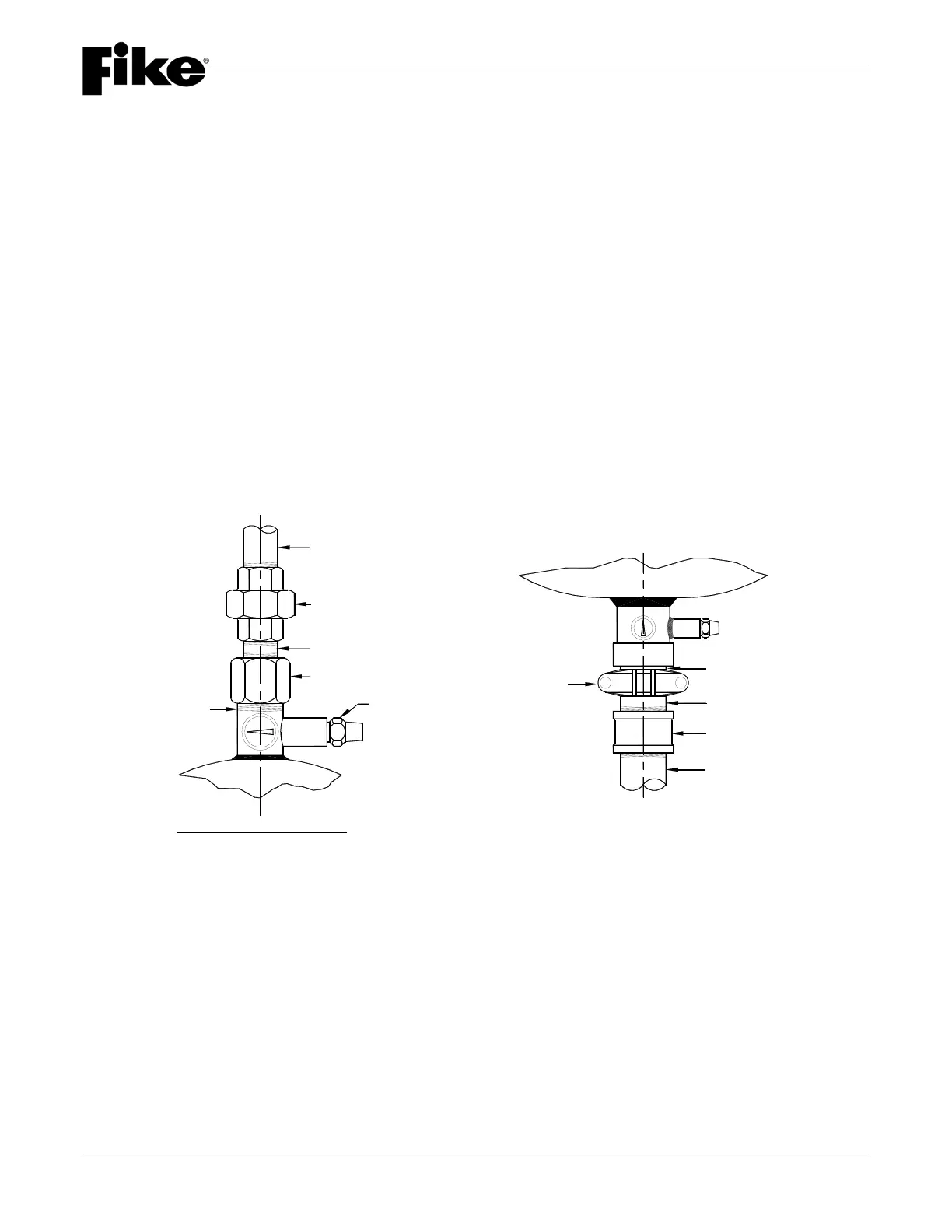

4.2.2 2-1/2" (65 mm) VALVE CONNECTIONS

The 2-1/2" (65 mm) valves used on the 125 & 215 lb. (15 & 90 L) containers have 2-1/2" (65 mm) grooves

machined into the outlets of the valves. The transition from the grooved outlet to pipe thread is made through the

use of an adapter nipple (supplied by Fike) that receives 2-1/2" (65mm) female pipe thread.

It is not necessary to supply a pipe union after the grooved coupling to facilitate removal of the container for

service or maintenance purposes.

IMPORTANT: Remove the Baffle Plate located inside the grooved coupling before connecting the discharge

piping to the container. The Baffle Plate is an anti-recoil device that must be installed whenever

transporting or handling charged containers that are not connected to the discharge piping.

1" (25 mm) DISCHARGE VALVE

STRAIGHT THREADS

2" (50 mm)

ADAPTER NUT

CLOSE NIPPLE

RETAINER NUT

DISCHARGE PIPING

GROOVED COUPLING

2 1/2" (65 mm)

DISCHARGE PIPING

ADAPTER NIPPLE

2 1/2" (65 mm)

COUPLING

OUTLET

1" NPT UNION

2 1/2" (65 mm) DISCHARGE VALVE

Loading...

Loading...