SECTION 2 – DESIGN

UL / ULC Ex4623 Fike Clean Agent System w/ FM-200™ Page 21 of 39

FM 3010715 Manual P/N: 06-215 (Rev G) Revision Date: January. 2010

2.8.4 ESTIMATING PIPE SIZE (ENGINEERED SYSTEMS)

The proper pipe size for each section of piping is selected based on the design flow rate for each pipe section.

Generally, the size selection should be based on the smallest pipe size that will handle the design flow rate for

branch lines supplying the discharge nozzles, and the next to smallest size for trunk lines.

2.8.4.1 DISCHARGE DURATION

HFC-227ea Systems must discharge the agent in a manner that will achieve 95% of the design concentration

within ten (10) seconds in accordance with NFPA 2001, Section 3. Fike HFC-227ea Systems have been tested

by UL and FM in accordance with this requirement, along with an additional requirement that requires the

minimum discharge time associated with an HFC-227ea to be no less than six (6) seconds.

Therefore, these time requirements must be taken into account when estimating pipe sizes. The Fike HFC-227ea

Flow Calculation Program selects pipe sizes based on these criteria and selects the nozzle orifice hole sizes

accordingly. Ultimate control of the discharge time is accomplished through the custom sizing of the discharge

nozzles by the Fike Program.

2.8.4.2 MINIMUM FLOW RATES

Flowing HFC-227ea agent actually consists of two phases: liquid and vapor. To accurately predict its flow

through a piping network, the piping has to be sized to provide enough resistance to create a turbulent flow effect.

When turbulent flow is achieved, the two phases join to form a homogenous mixture that can be accurately

calculated. If the pipe size is too large, phase separation will occur and the flow cannot be predicted. Therefore,

the pipe sizes selected must be in accordance with the Flow Rate Table below.

To determine the flow rate of a pipe section, divide the amount of agent flowing through that section by the

discharge time (10 seconds).

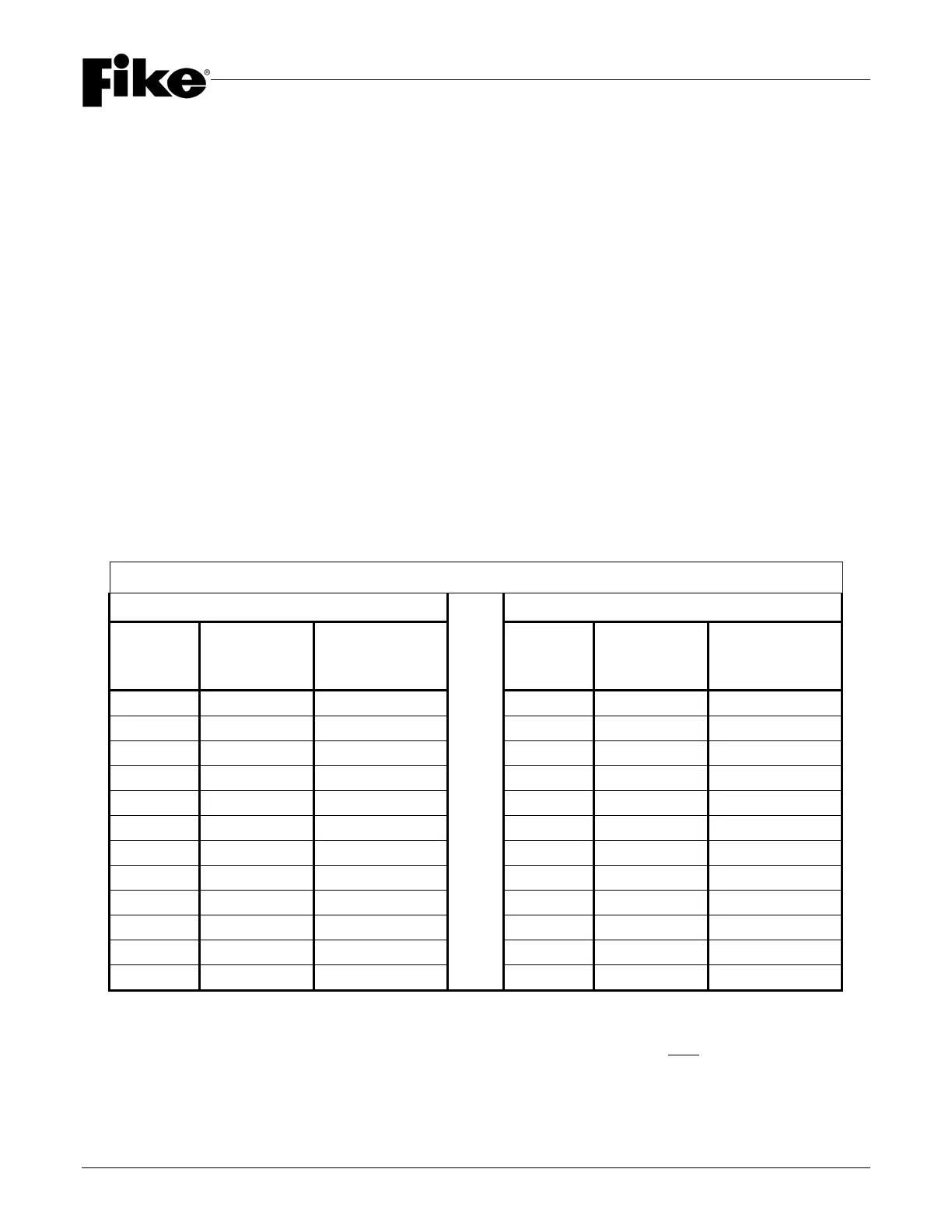

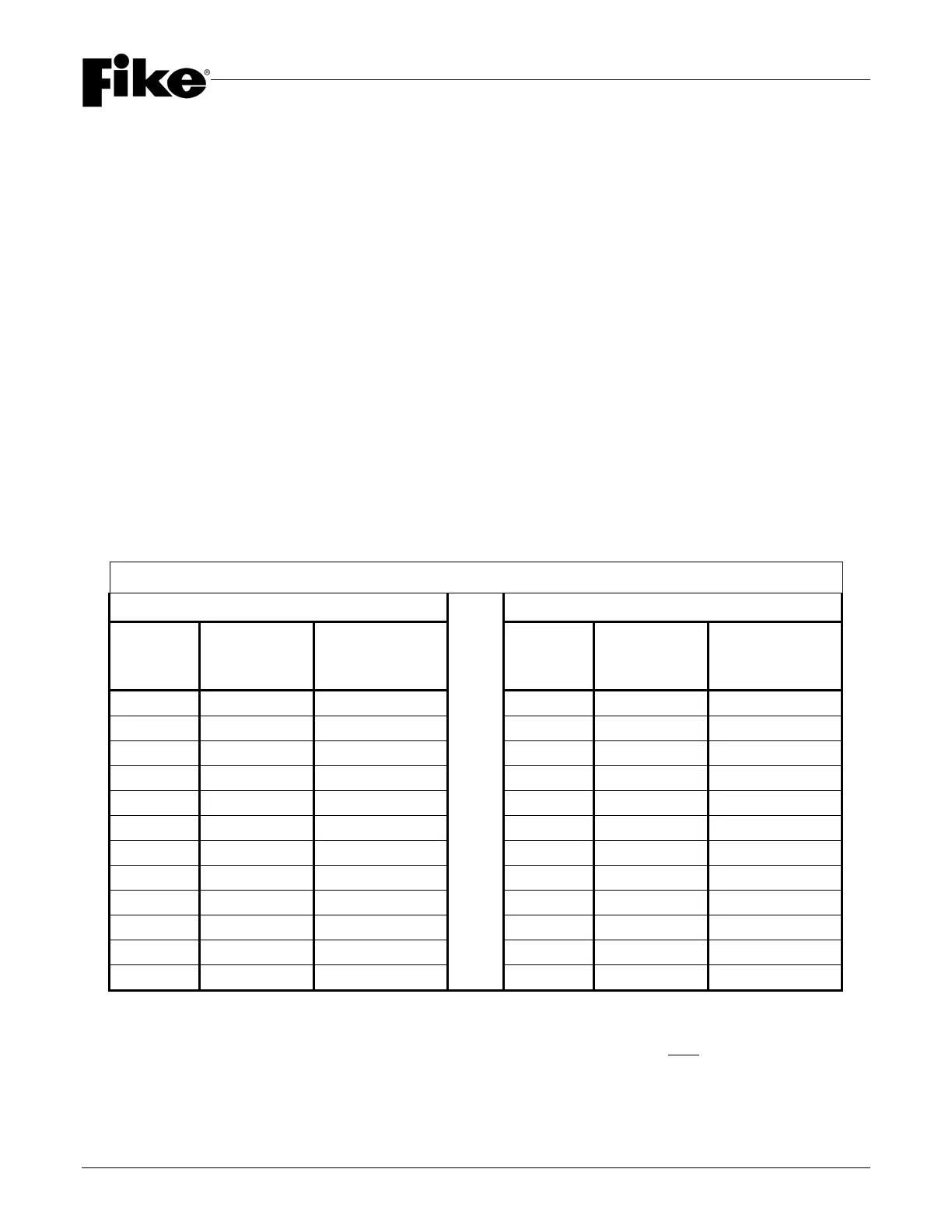

PIPE SIZE ESTIMATING TABLE

English Pipe Sizes Metric Pipe Sizes

Pipe Size

NPT

Min. Design

Flow Rate

(Limitation)

Max. Design

Flow Rate

(Estimate)

Pipe Size

Metric

Min. Design

Flow Rate

(Limitation)

Max. Design

Flow Rate

(Estimate)

3/8” 0.7 lbs./sec. 2.0 lbs./sec. 10 mm 0.32 kg/sec. 0.91 kg/sec.

1/2” 1.0 lbs./sec. 3.4 lbs./sec. 15 mm 0.45 kg/sec. 1.54 kg/sec.

3/4” 2.0 lbs./sec. 6.0 lbs./sec. 20 mm 0.91 kg/sec. 2.72 kg/sec.

1” 3.4 lbs./sec. 8.5 lbs./sec. 25 mm 1.54 kg/sec. 3.86 kg/sec.

1-1/4” 5.8 lbs./sec. 13.0 lbs./sec. 32 mm 2.63 kg/sec. 5.90 kg/sec.

1-1/2” 8.4 lbs./sec. 19.5 lbs./sec. 40 mm 3.81 kg/sec. 8.85 kg/sec.

2” 13.0 lbs./sec. 33.0 lbs./sec. 50 mm 5.90 kg/sec. 14.97 kg/sec.

2-1/2” 19.5 lbs./sec. 58.0 lbs./sec. 65 mm 8.85 kg/sec. 26.31 kg/sec.

3” 33.0 lbs./sec. 95.0 lbs./sec. 80mm 15.00 kg/sec. 43.10 kg/sec.

4” 58.0 lbs./sec. 127 lbs./sec. 100 mm 26.31 kg/sec. 57.61 kg/sec.

5” 95 lbs./sec. 222 lbs./sec. 125 mm 43.10 kg/sec. 100.70 kg/sec.

6” 127 lbs./sec. 318 lbs./sec. 150 mm 57.61 kg/sec. 144.24 kg/sec.

WARNING: DO NOT install the pipe system based on estimates from this chart. The pipe system design

MUST be verified by the Fike HFC-227ea Flow Calculation Program prior

to installing the system.

Loading...

Loading...