SECTION 4 – SYSTEM INSTALLATION

UL / ULC Ex4623 Fike Clean Agent System w/ FM-200™ Page 21 of 21

FM 3010715 Manual P/N: 06-215 (Rev G) Revision Date: January, 2010

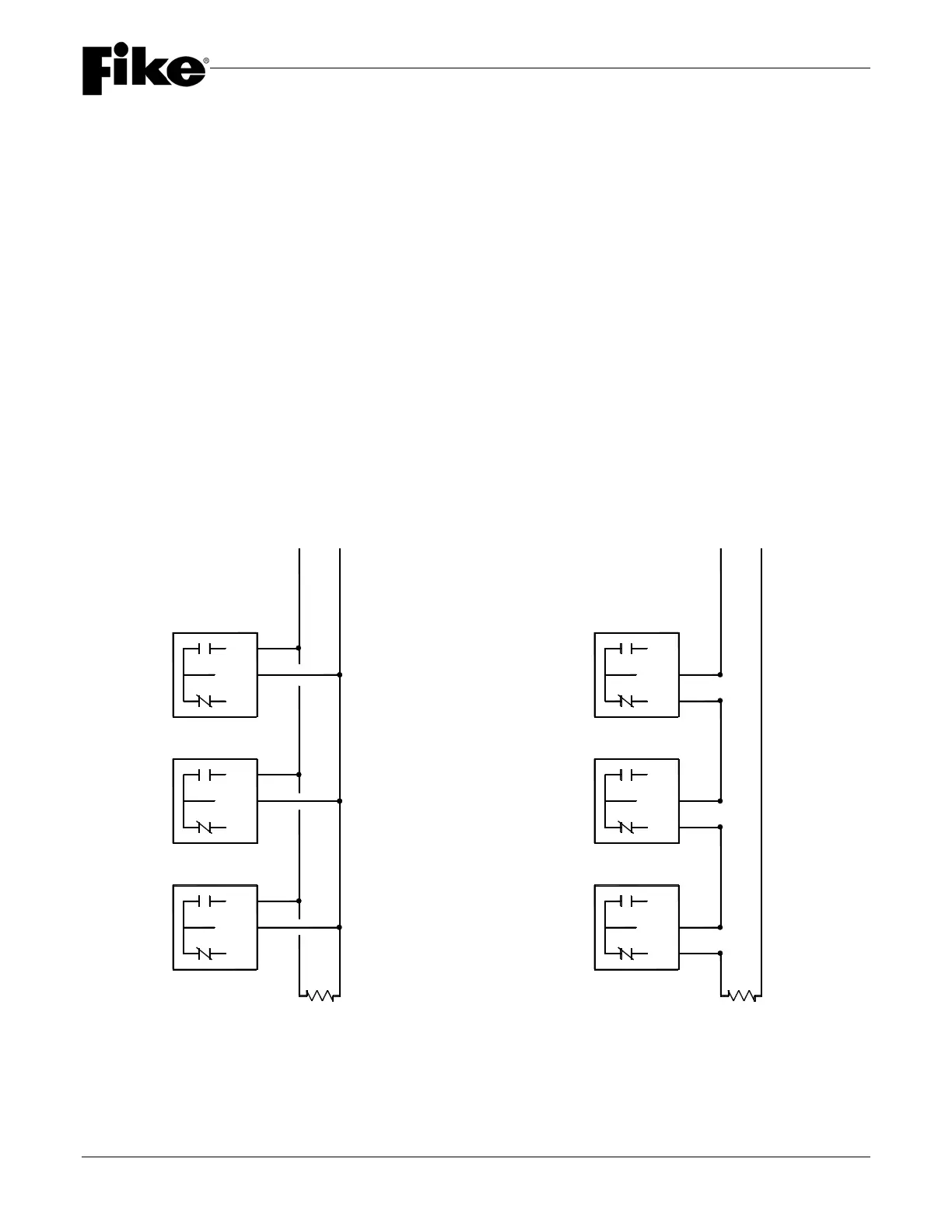

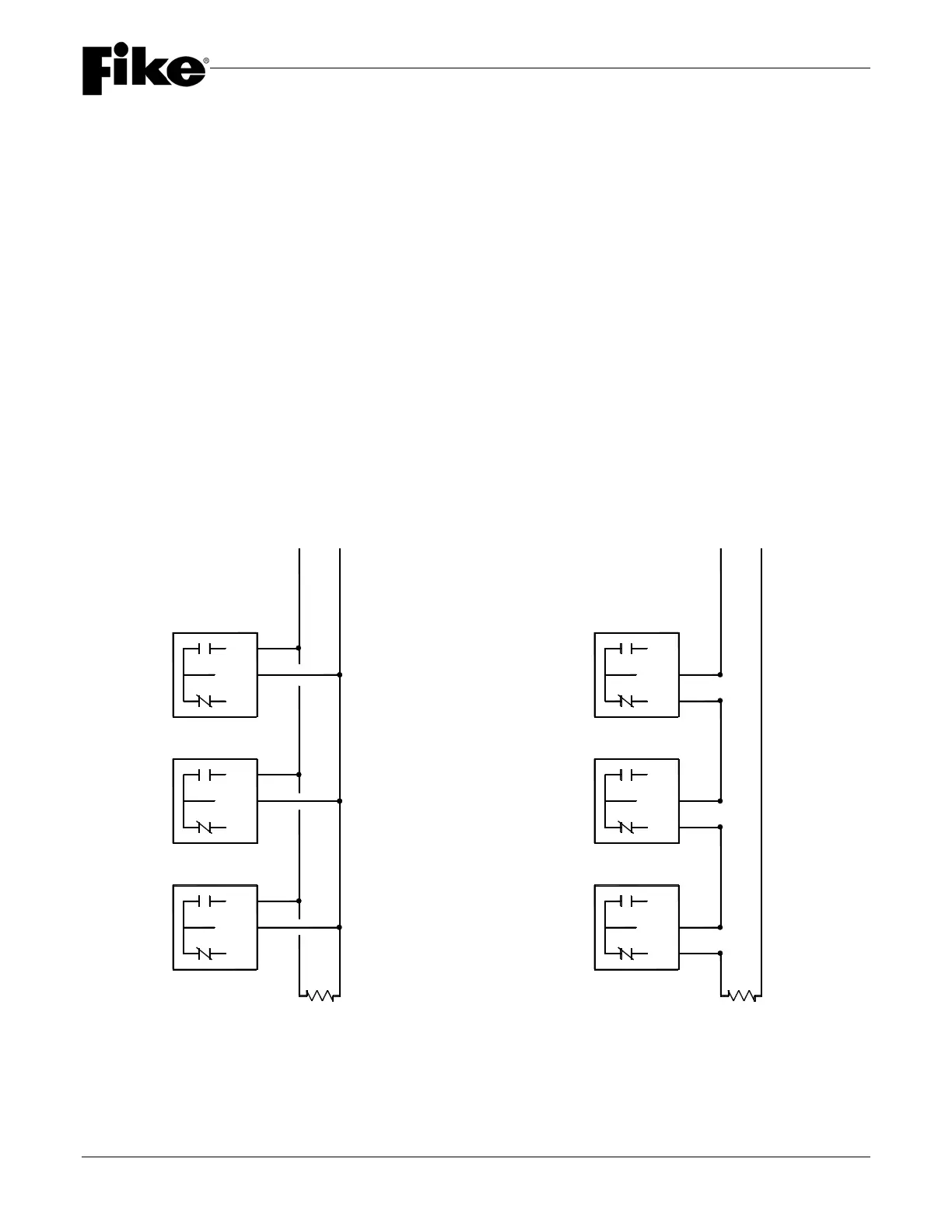

4.8.1 LOW PRESSURE SWITCH WIRING

The Low Pressure Switch can be wired for either of two configurations: normally open or normally closed shelf-

state (de-energized) conditions. When the container is filled and pressurized, the contacts change state. For

example, a normally open switch configuration will be closed when the container is pressurized. If the pressure in

the container drops below 288 psig (196.5 bar kPa), the contact will return to the open (de-energized) position.

The pressure switch should be wired into a supervised circuit in the control panel used to provide a trouble signal

if the container sees a low-pressure condition. The preferred method would be to wire the switch normally open

(closed under pressure).

For applications utilizing a U.L. listed and FMRC approved Cheetah panel, one switch per FRCM (Fast Response

Contact Module) is recommended. Refer to the Installation, Operation & Maintenance Manual for the control

panel being used for specific wiring criteria.

Note:

When the cylinder low pressure switch (p/n 02-9830) is connected to a standard supervisory input circuit, there

will be no distinction between a wiring fault and device actuation. This device is to only be utilized when accepted

by the authority having jurisdiction.

VIOLET

BLUE

N/O

N/C

COM

VIOLET

BLUE

N/C

COM

N/O

VIOLET

BLUE

N/C

COM

N/O

SUPERVISORY

CIRCUIT

N/C

COM

N/O

E.O.L.

BLACK

VIOLET

N/C

COM

N/O

N/C

COM

N/O

BLACK

VIOLET

VIOLET

BLACK

CIRCUIT

SUPERVISORY

E.O.L.

Loading...

Loading...