SECTION 2 – DESIGN

Page 26 of 39 Fike Clean Agent System w/ FM-200™ UL / ULC Ex4623

Revision Date: January, 2010 Manual P/N: 06-215 (Rev G) FM 3010715

2.10 MANIFOLD OPTIONS (ENGINEERED SYSTEMS)

Sometimes, a system will require more agent than a single container can provide. In this case, multiple

containers can be connected together via a common manifold arrangement. Main and Reserve supplies of agent

are also connected together in this manner.

Manifolds are assembled using a combination of grooved pipe and grooved fittings, or threaded pipe and fittings

meeting the pressure requirements of NFPA 2001, Section 2. Every container must be the same type, same size,

and identical fill weight in accordance with NFPA 2001, Section 2. 3” NPT (80 mm) Check Valves are required for

EACH container in accordance with NFPA 2001, Section 2.

Manifold assemblies are configured using 3” (80 mm) through 6” (150 mm) pipe sizes, depending upon the

amount of agent being supplied. The common manifold types are as follows:

Center Exit Manifold

End Exit Manifold

Center Exit Manifold / Main and Reserve

End Exit Manifold / Main and Reserve

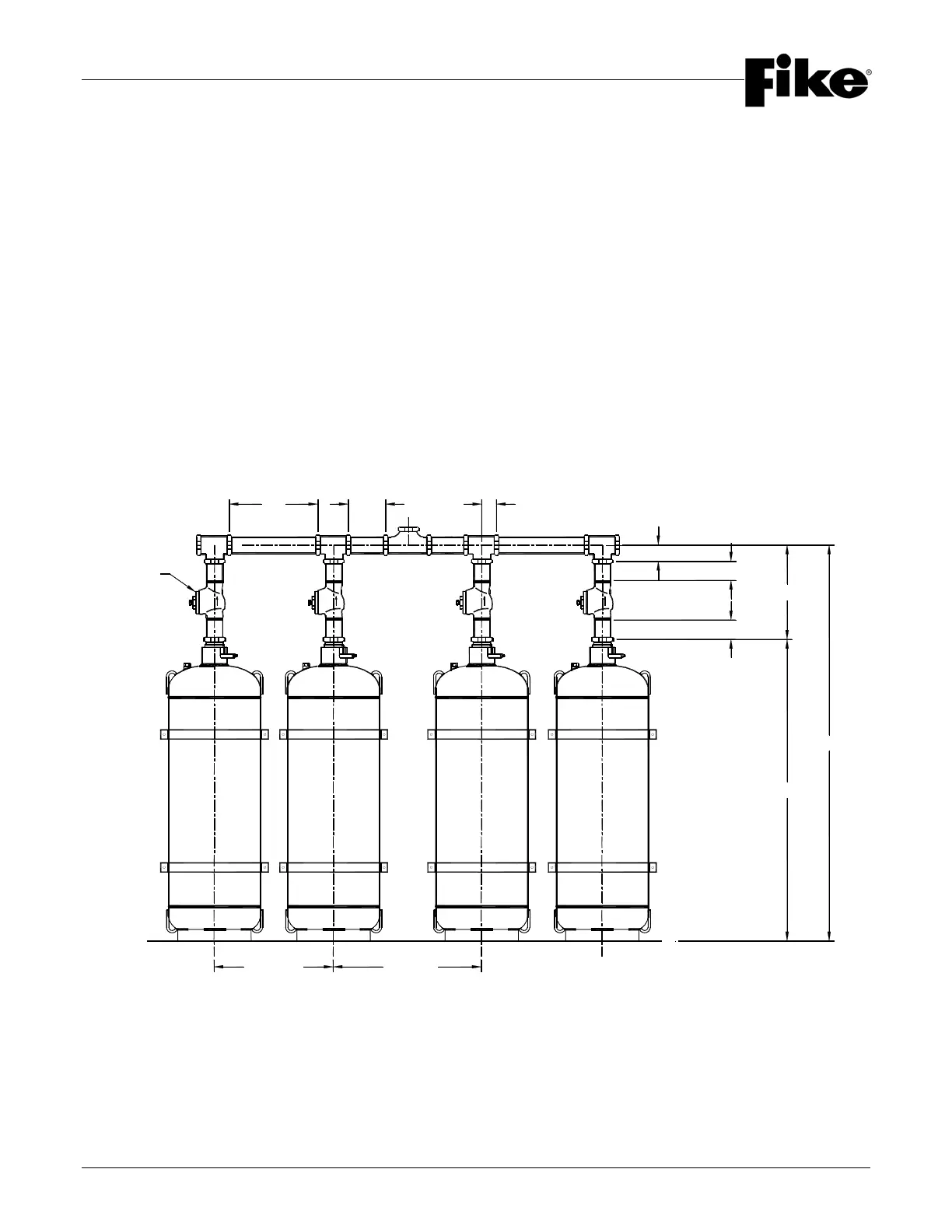

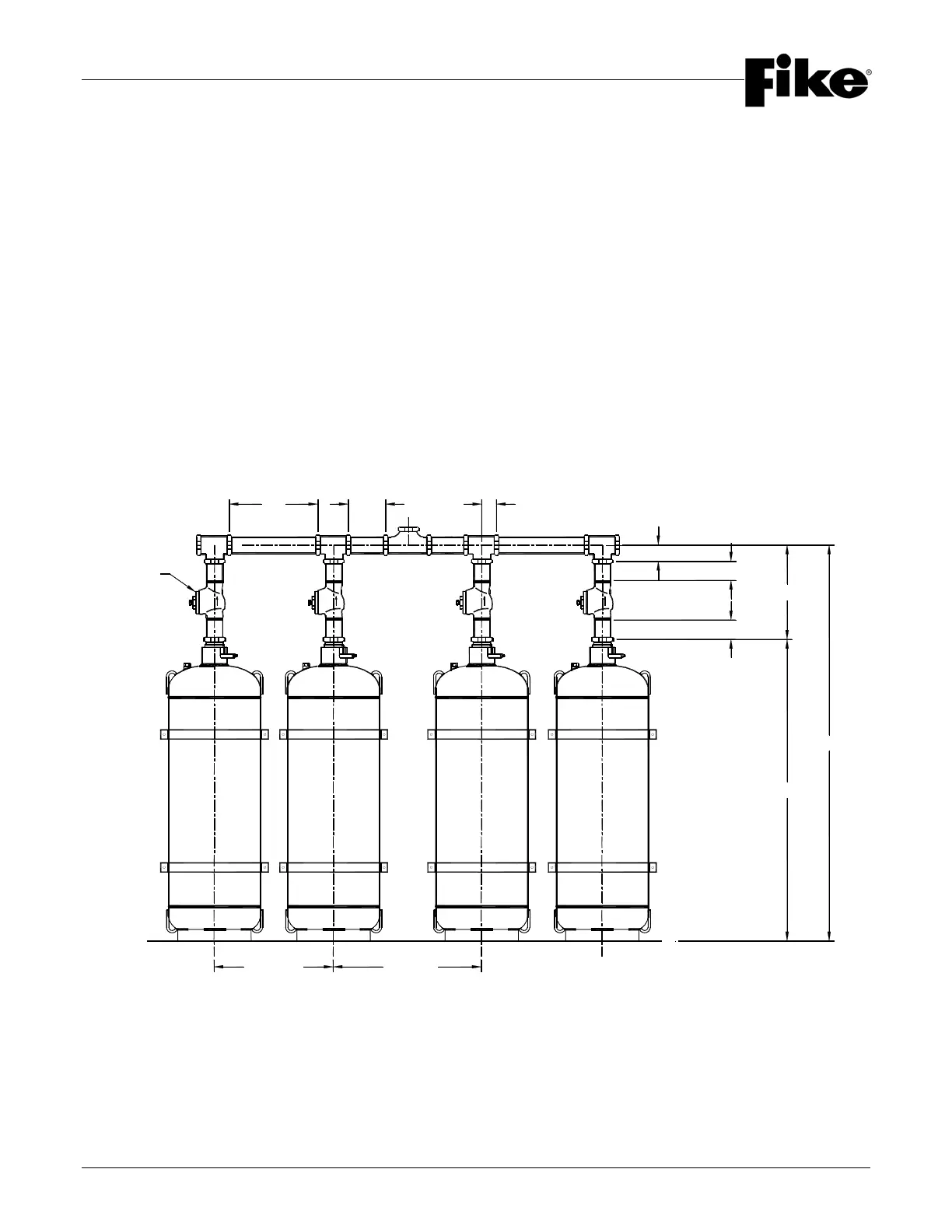

The following diagrams and table show the basic manifold configurations and dimensions. Refer to Section 4 for

additional installation information.

CHECK

VALVE

EE

S S

EE

S

V

EL

CE

l

T

EL

CE

CE

r

30"

(762 mm)

38"

(965 mm)

3" (76 mm)

3" (76 mm)

CENTER EXIT MANIFOLD / 3” THRU 6” (80 mm thru 150 mm)

OR

MAIN & RESERVE MANIFOLD / 3” THRU 6” (80 mm thru 150 mm)

Loading...

Loading...