SECTION 2 – DESIGN

UL / ULC Ex4623 Fike Clean Agent System w/ FM-200™ Page 29 of 39

FM 3010715 Manual P/N: 06-215 (Rev G) Revision Date: January. 2010

2.11 PRE-ENGINEERED SYSTEMS DESIGN

Pre-Engineered Systems are simple 1, 2 or 4 nozzle configurations that have been pre-tested in accordance with

NFPA 2001, UL and FM requirements. The Pre-Engineered concept minimizes the engineering effort required to

design an effective system. As long as nozzle selection, pipe size and pipe length limitations are adhered to,

hydraulic flow calculations are not required. The designer will perform a simple hand calculation to determine a

Total Pressure Drop (TPD) value. If the TPD value is less than 100 (35 for 10 lb/4 L cylinders), the system is

acceptable.

Fike Pre-Engineered Systems MUST be designed and installed within the limitations that follow.

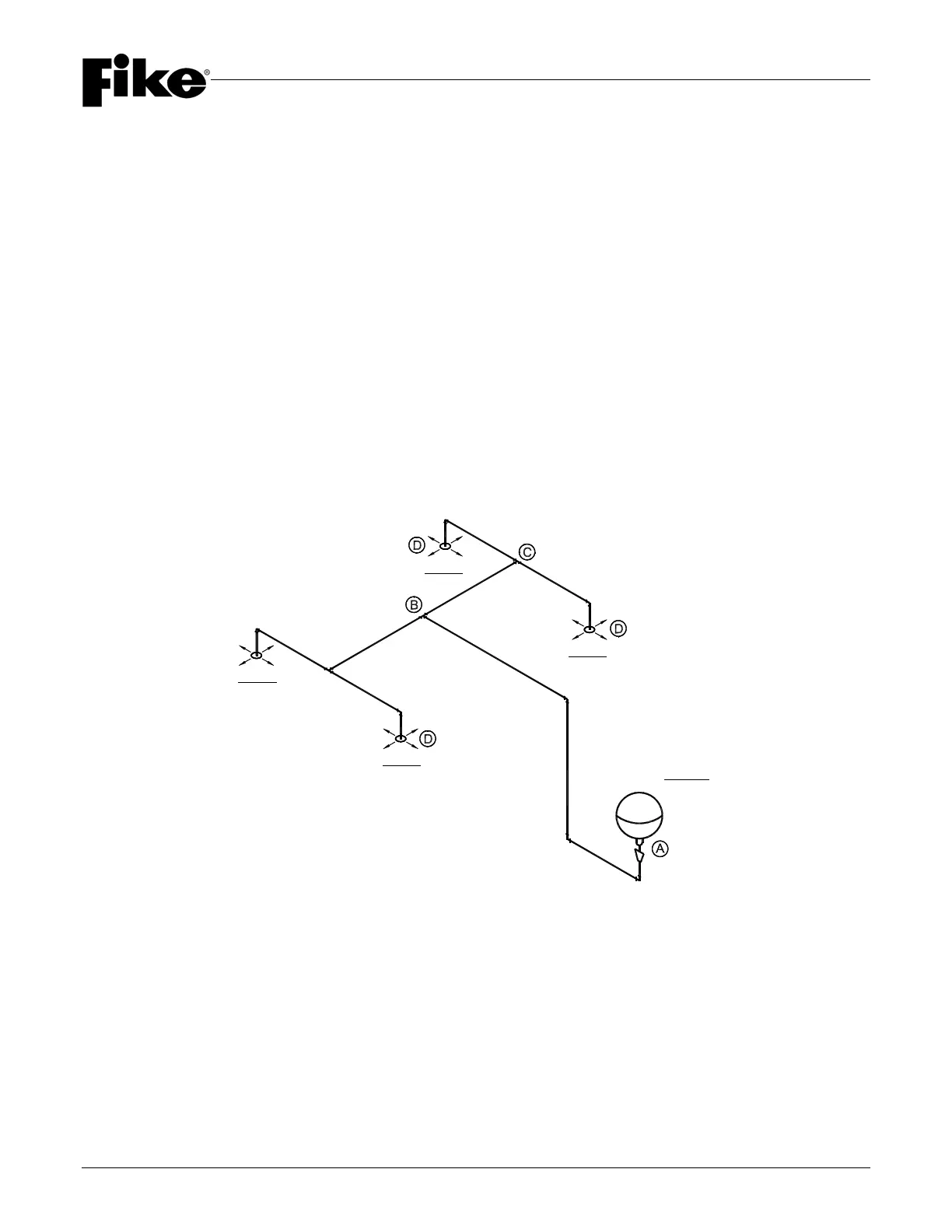

2.11.1 PIPING LAYOUT

After the quantity of nozzles and container locations have been selected, the piping system layout can be

determined. The configuration can be as simple as a single nozzle, or additional nozzles can be added in a two

(2) or four (4) nozzle configuration. Storage containers shall be located as close as possible to or within the

hazard or hazards they protect. (Reference: NFPA 2001, Section 2)

When designing a two or four nozzle Pre-Engineered System, the nozzle and piping layout MUST be installed in a

balanced configuration. To accomplish this, the flow path from the container to each nozzle must be the same

length, using the same pipe sizes, the same quantity and type of fittings, and the nozzles must discharge the

same amount of agent from each nozzle. A piping network is considered to be balanced if the total length from

the container to each nozzle is within 10% of each other.

In addition, all tee splits MUST be made using a Bullhead Tee configuration, and each outlet must be oriented in

the horizontal plane. Refer to the diagram below.

2.11.2 DETERMINING PIPE SIZES

Pipe Sizes have already been pre-determined for Pre-Engineered Systems depending upon the size of the

container and the number of nozzles needed for each system. Refer to one of the following tables.

Single Nozzle Piping Table, 35 lb. thru 215 lb. (15 thru 87 L) Containers

Two Nozzle Piping Table, 60 lb. thru 375 lb. (27 thru 153 L) Containers

Four Nozzle Piping Table, 100 lb. thru 1000 lb. (44 thru 423 L) Containers

(15.9 kg)

35 lbs.

(15.9 kg)

35 lbs.

35 lbs.

(15.9 kg)

35 lbs.

(15.9 kg)

140 lbs.

(63.5 kg)

Loading...

Loading...