SECTION 2 – DESIGN

UL / ULC Ex4623 Fike Clean Agent System w/ FM-200™ Page 7 of 39

FM 3010715 Manual P/N: 06-215 (Rev G) Revision Date: January. 2010

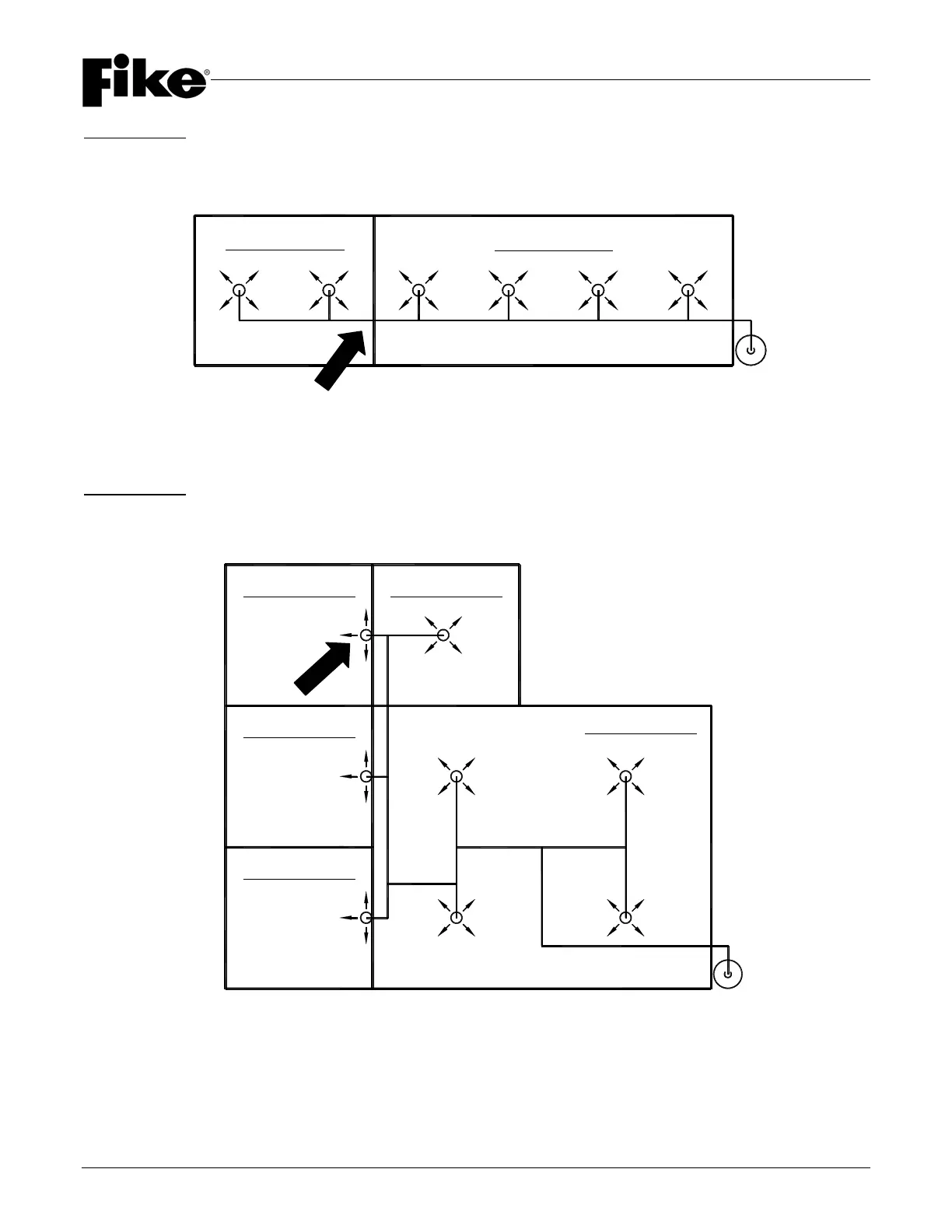

Example No. 1: This example shows a simple, two hazard application. Starting at the point where the piping

enters the hazard that is farthest away (hydraulically) from the container, count the number of tees leading back to

the supply container.

With a tee count of four (4), refer to the Tee Design Factor Table and determine the multiplier required. With this

quantity, an additional 0% (0.00) of agent is required. Therefore, the base quantity of agent calculated is correct.

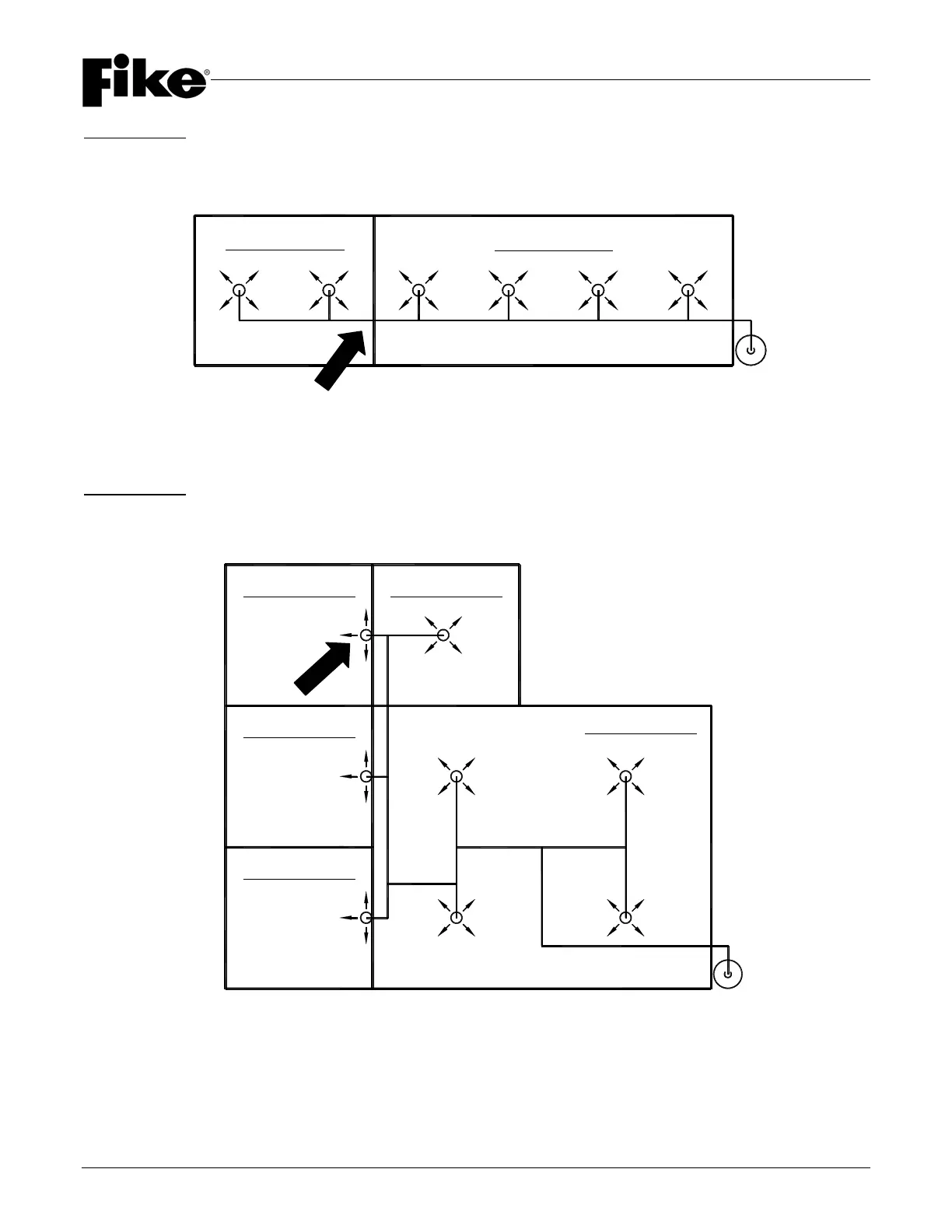

Example No. 2

: This example shows a multi-hazard area arrangement. Starting at the point where the piping

enters the hazard farthest away, count the number of tees leading back to the supply container. If you are not

sure which hazard is the farthest away, count each hazard and use the highest number.

With a tee count of six (6), refer to the Tee Design Factor Table and determine the multiplier required. With this

quantity, an additional 2% (0.02) of agent is required. Therefore, the base quantity of agent is multiplied by 1.02

(2%) to determine the adjusted quantity of agent required.

HAZARD #1

#1 #2 #3 #4

HAZARD #2

START HERE

HAZARD #5HAZARD #4

HAZARD #3

HAZARD #2

HAZARD #1

#1

#2

#3

#4

#5

#6

HERE

START

Loading...

Loading...