SECTION 3 – SAMPLE PROBLEM

Page 6 of 17 Fike Clean Agent System w/ FM-200™ UL / ULC Ex4623

Revision Date: January, 2010 Manual P/N: 06-215 (Rev G) FM 3010715

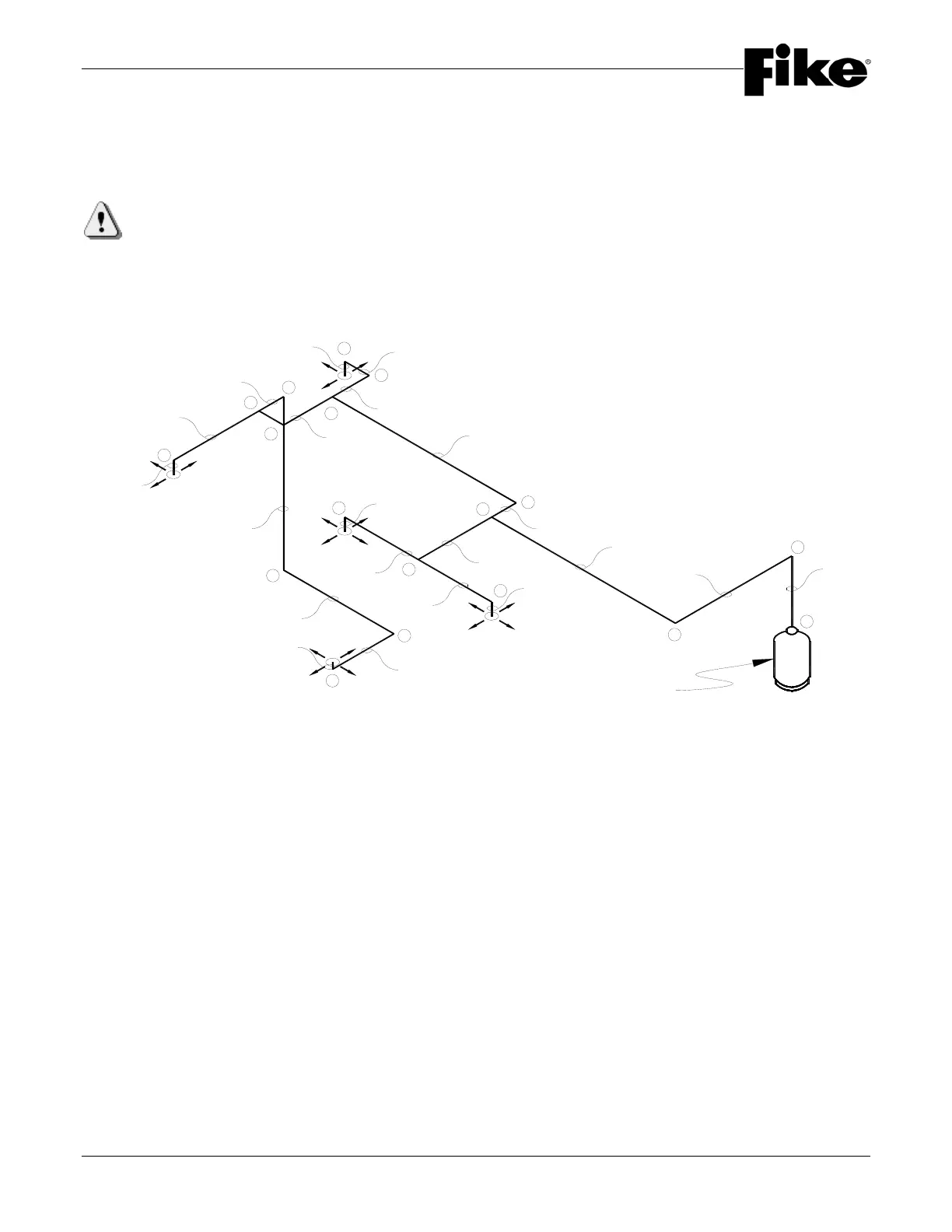

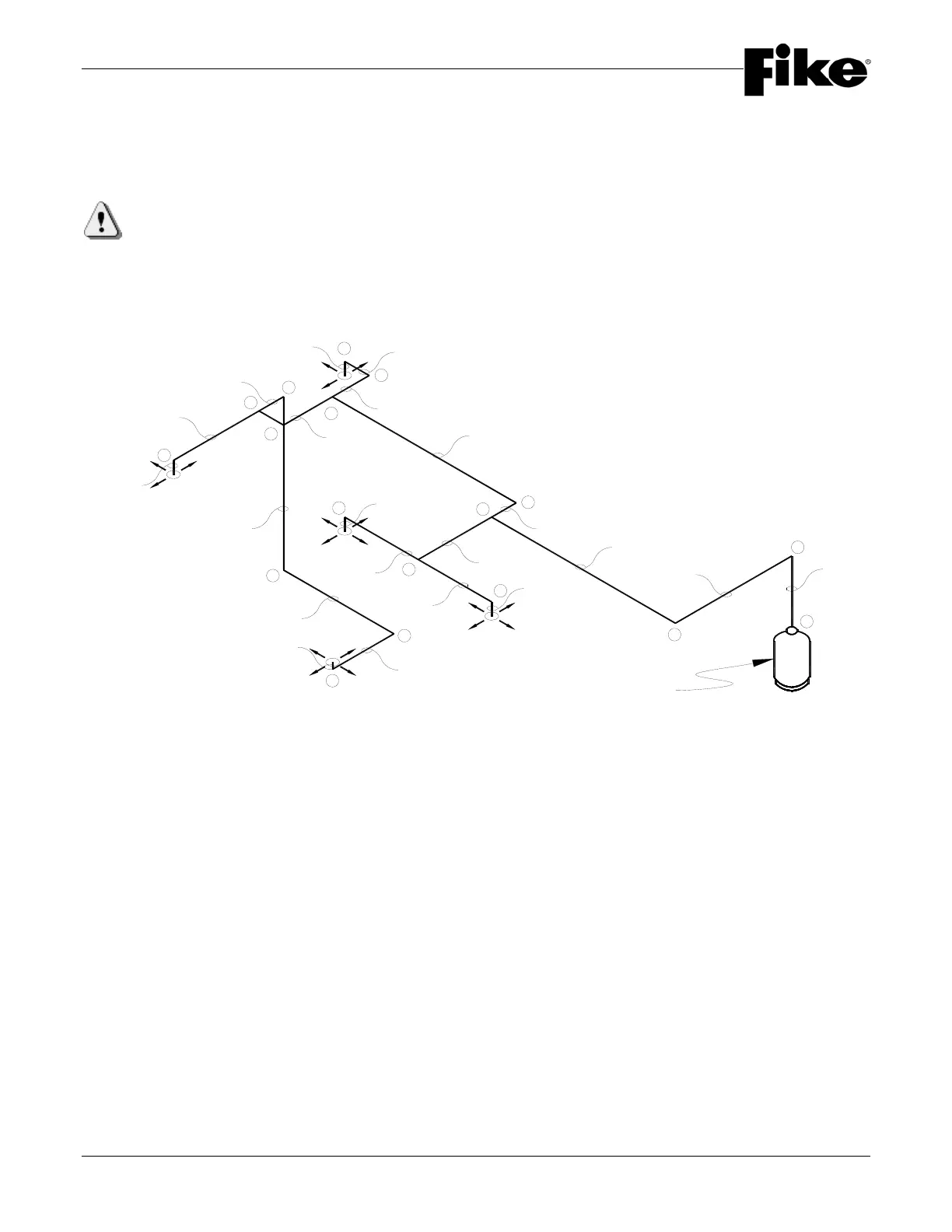

Step 2: Layout a piping isometric to show all elevation changes, fittings, pipe sizes and lengths. Pipe

sizes will be based on the flow rate for each section and selected from Table 2.6.3. Check the piping

network for tee split ratios, tee orientation, minimum piping distances, proper nozzle screen quantity and

location, etc.

IMPORTANT: Your final design “must” be checked by using Fike's HFC-227ea Engineered System Flow

Calculation Program before installation starts. When using the “Isometric” input portion of the flow

calculation program, it is not necessary to assign “Node” points to the piping isometric as the isometric

input will automatically assign node point numbers as you draw the piping system.

1

2

3

4

10

5

6

8

11

21

22

12

16

13

14

17

18

19

E1-N1

E1-N2

E2-N1

E3-N1

E4-N1

5' (1.5m)

15' (4.6m)

2.0' (0.6m)

1' (0.3m)

6' (1.8m)

1.0' (0.3m)

6' (1.8m)

6' (1.8m)

15' (4.6m)

3' (0.9m)

4' (1.3m)

2' (0.6m)

1' (0.3m)

2' (0.6m)

7' (2.1m)

1' (0.3m)

12'-3" (3.7m)

9' (2.7m)

5' (1.5m)

0.5' (0.2m)

650 lb. Container

9'-6" (2.9m)

FIGURE 3.4-C

The following pages are a copy of the Fike's HFC-227ea Engineered System Flow Calculation Program printout

showing the inputs and outputs of the program.

Loading...

Loading...