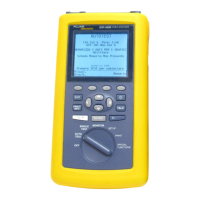

DSX-600 CableAnalyzer

Technical Reference Handbook

122

A test passes, but the plot shows that measurements exceed the limit

A dB rule possibly applies. See “About dB Rules” on page 90.

Resistance test gives a FAIL, FAIL*, or PASS* result

Link is too long (may need to remove coiled service loops)

Bad connection due to oxidized or loose contacts

Wire gauge is too thin

Wires in a pair have too much difference in the number of twists

(resistance is unbalanced)

Wrong type of patch cord used

Notes

The HDTDR analyzer can help you locate the cause of

a resistance failure. See page 137.

To do the resistance test continuously while you look

for a fault, tap TOOLS > Single Tests > Resistance.

Length gives a FAIL result

Link is too long (may need to remove coiled service loops)

NVP is set incorrectly

Note

To do the length test continuously while you look for

a fault, tap TOOLS > Single Tests > Length.

Length exceeds the limit, but the length test did not fail

If the length of the shortest pair does not exceed the limit by 10 %, then the

length test passes even if other pairs exceed the limit. This is the 10 % rule for

length, as given in the ANSI/TIA standard. See the Fluke Networks Knowledge

base for details.

Propagation delay or delay skew gives a FAIL result

Link is too long (may need to remove coiled service loops)

Cable has different insulation materials on different pairs. This causes

differences in the twist ratios, which causes differences in propagation

delays among pairs.

Table 7. Causes of Twisted Pair Test Failures (continued)

Loading...

Loading...