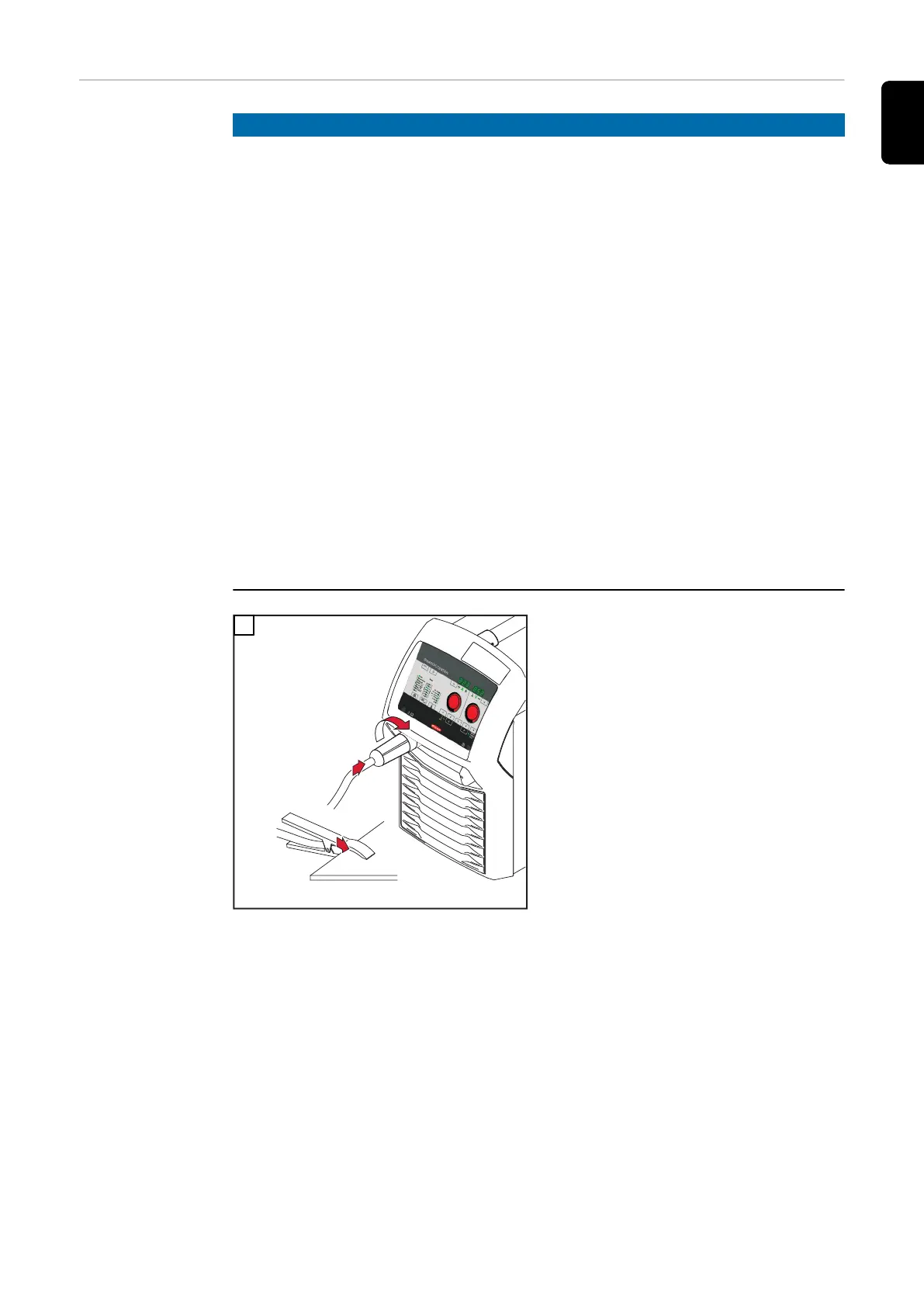

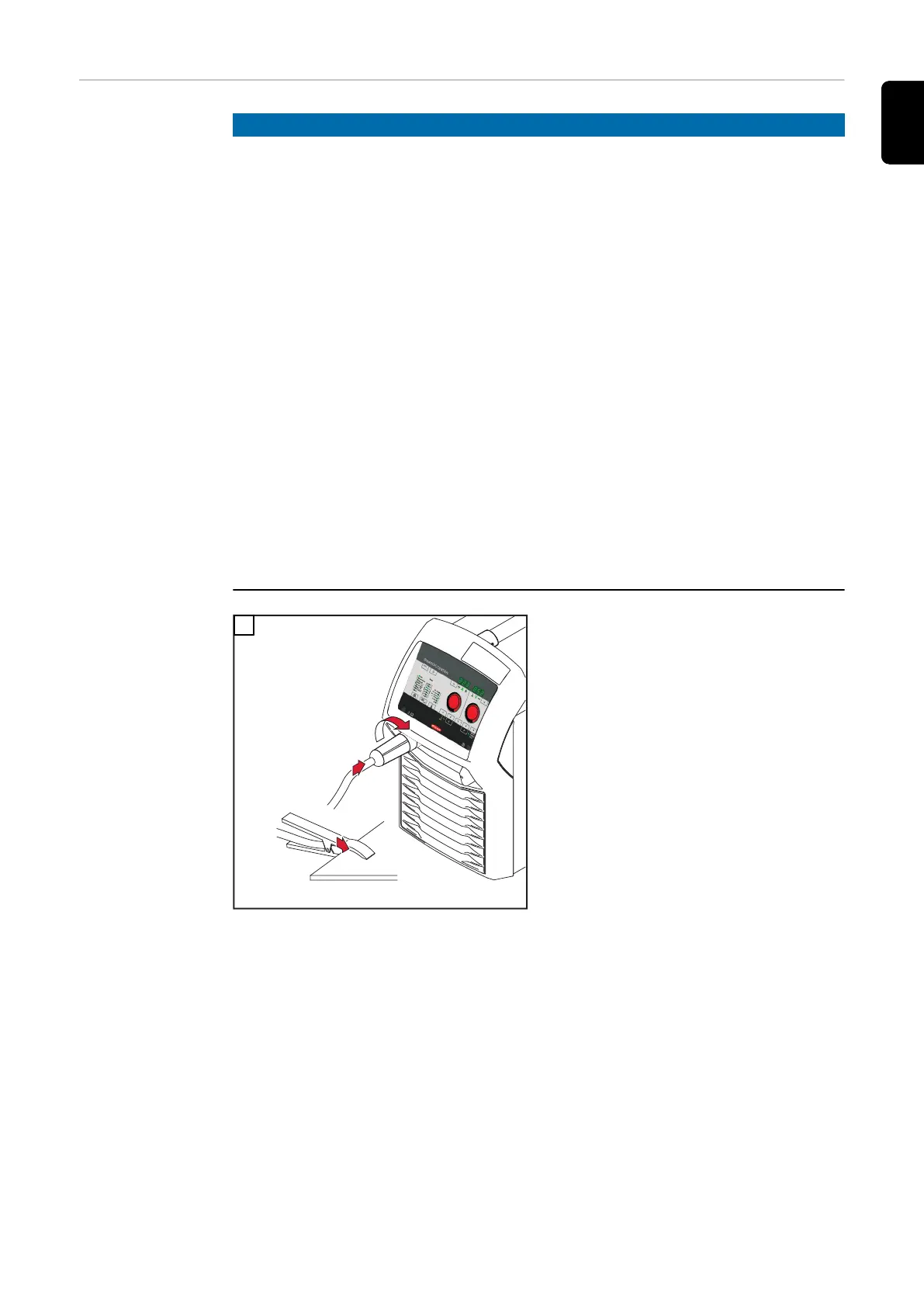

Establishing a

ground earth

connection

NOTE!

When establishing a ground earth connection, observe the following points:

▶

Use a separate grounding cable for each power source

▶

Keep positive cables and grounding cables together as long and as close as

possible

▶

Physically separate the welding circuits of individual power sources

▶

Do not route several grounding cables in parallel;

if parallel routing cannot be avoided, keep a minimum distance of 30 cm

between the welding circuits

▶

Keep the grounding cables as short as possible, provide a large cable cross-

section

▶

Do not cross over grounding cables

▶

Avoid ferromagnetic materials between the grounding cables and the inter-

connecting hosepack

▶

Do not wind long grounding cables - coil effect!

Route long grounding cables in loops

▶

Do not route grounding cables in iron pipes, metal cable trays, or on steel

beams, avoid cable ducts;

(routing positive cables and grounding cables together in an iron pipe does

not cause any problems)

▶

If several grounding cables are used, separate the part's ground points as far

as possible and do not allow crossed current paths under the individual arcs.

▶

Use compensated interconnecting hosepacks (interconnecting hosepacks

with integrated grounding cable)

1

57

EN-US

Loading...

Loading...