4.10 Operation Check

4-42

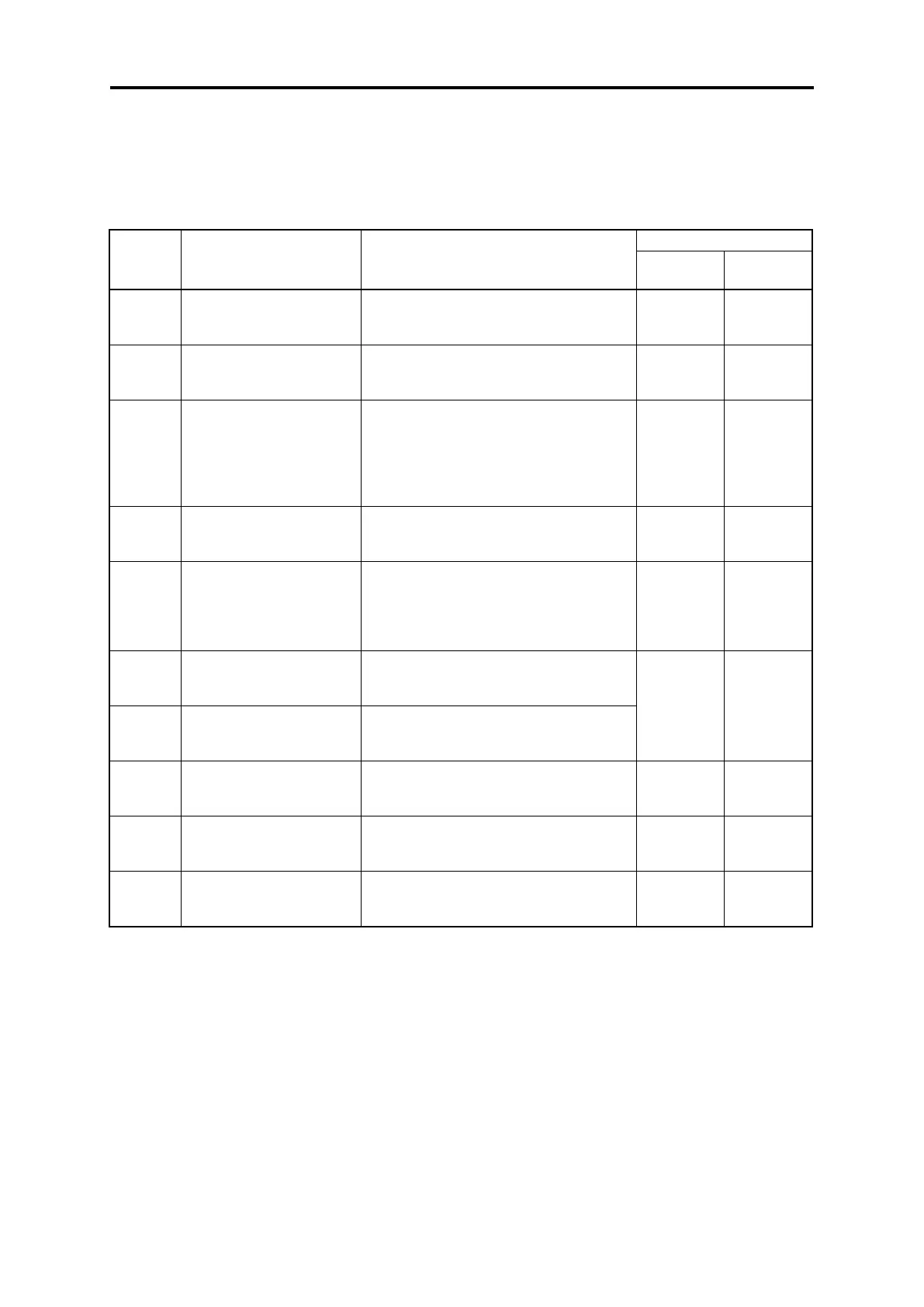

4.10.3 Adjusting the function code for motor control

Adjusting the current function code data sometimes resolve issues such as insufficient torque or overcurrent.

Table 4.9 1 lists the major function codes to be accessed.

Refer to Chapter 5 “FUNCTION CODES” and Chapter 6 “TROUBLESHOOTING” for details.

Table 4.10-1

If the current limiter is activated due to a

short acceleration time and large drive

current, prolong the acceleration time.

If an overvoltage trip occurs due to a short

deceleration time, prolong the deceleration

time.

If the starting motor torque is deficient

under V/f control mode, increase the

torque boost.

If the motor with no load is overexcited

(current increasing), decrease the torque

boost.

If the stall prevention function is activated

by the current limiter during acceleration or

deceleration, increase the operation level.

If the starting motor torque is insufficient

under automatic torque boost and torque

vector control, increase %R1. If the motor

with no load is over-excited (current

increasing), decrease %R1.

Motor 1

(Slip compensation gain for

driving)

For excessive slip compensation during

driving, decrease the gain; for insufficient

one, increase the gain.

V/f

(sensorless)

(sensorless

vector)

Motor 1

(Slip compensation gain for

braking)

For excessive slip compensation during

braking, decrease the gain; for insufficient

one, increase the gain.

Curve

acceleration/deceleration

If overshoot to the change in speed

command is large, make curve

acceleration/deceleration speed effective.

Anti-regenerative control

If an overvoltage alarm occurs without a

braking resistor, enable the

anti-regenerative control function.

Output current fluctuation

damping gain for motor 1

If motor current vibration occurs, adjust in

the direction that increases the damping

gain.

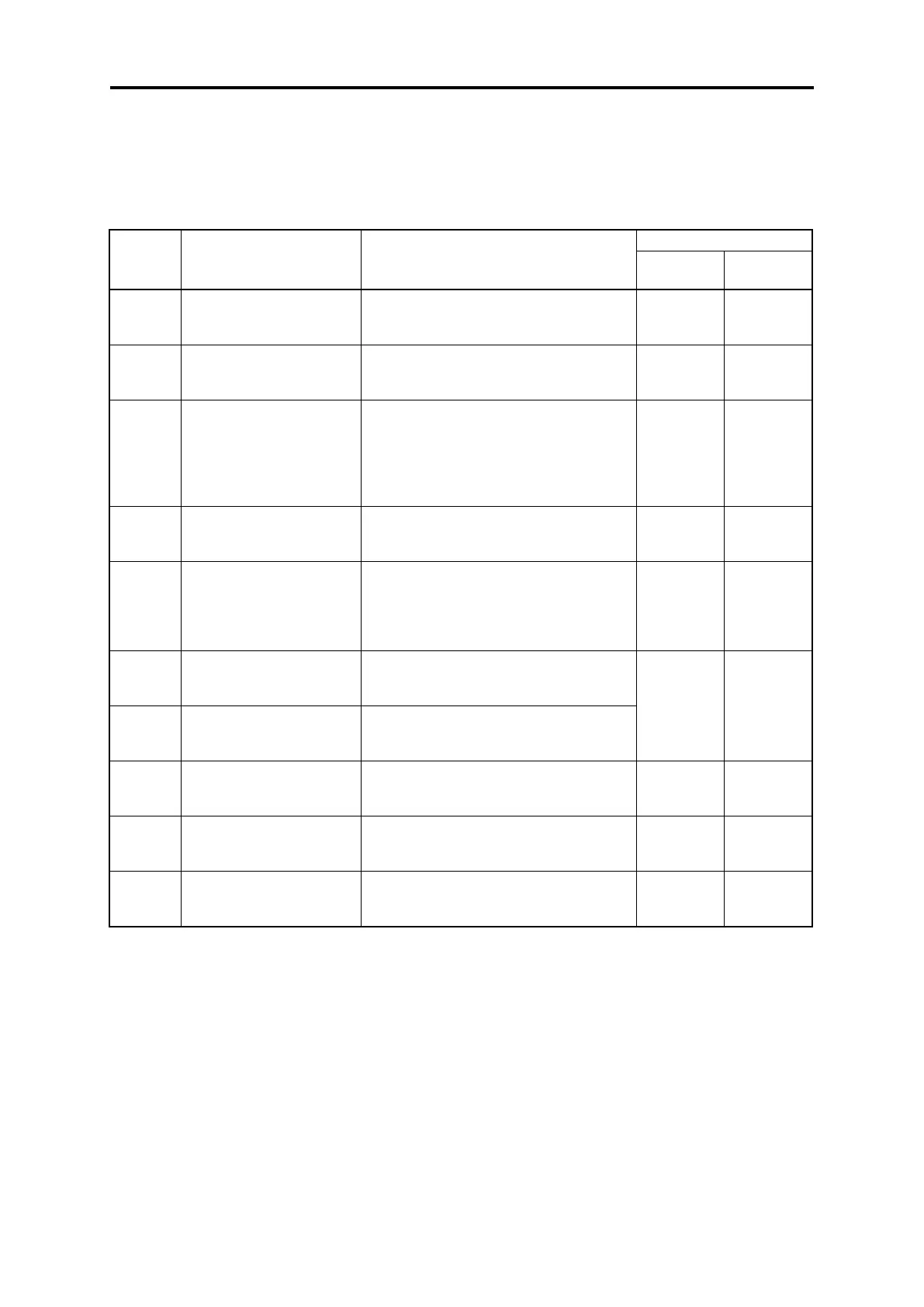

If there is no improvement by adjusting the above function codes when performing V/f control with sensor, with

sensor/sensorless vector control, with sensor/sensorless vector control for synchronous motors, adjust the

following function codes also. In the above control methods, PI regulator is used for speed control. The desired

response can be obtained by adjusting the control constants (PI constants) to match the load inertia. The major

function codes to adjust are shown below.

Loading...

Loading...