11.8 Braking Resistors (DB) and Braking Units

11-17

SELECTING PERIPHERAL EQUIPMENT

11.8.2 Overview of Braking Resistors (DB) and Braking Units

A braking resistor converts regenerative energy generated from the deceleration of the motor to heat. Use of a

braking resistor results in improved deceleration performance of the inverter. FRENIC-MEGA (GS2) 200V series

FRN0288G2S-2G or lower models and 400V series FRN0180G2□-4G or lower models are equipped with built-in

braking resistor drive transistors, allowing braking resistors to be connected directly to the inverter.

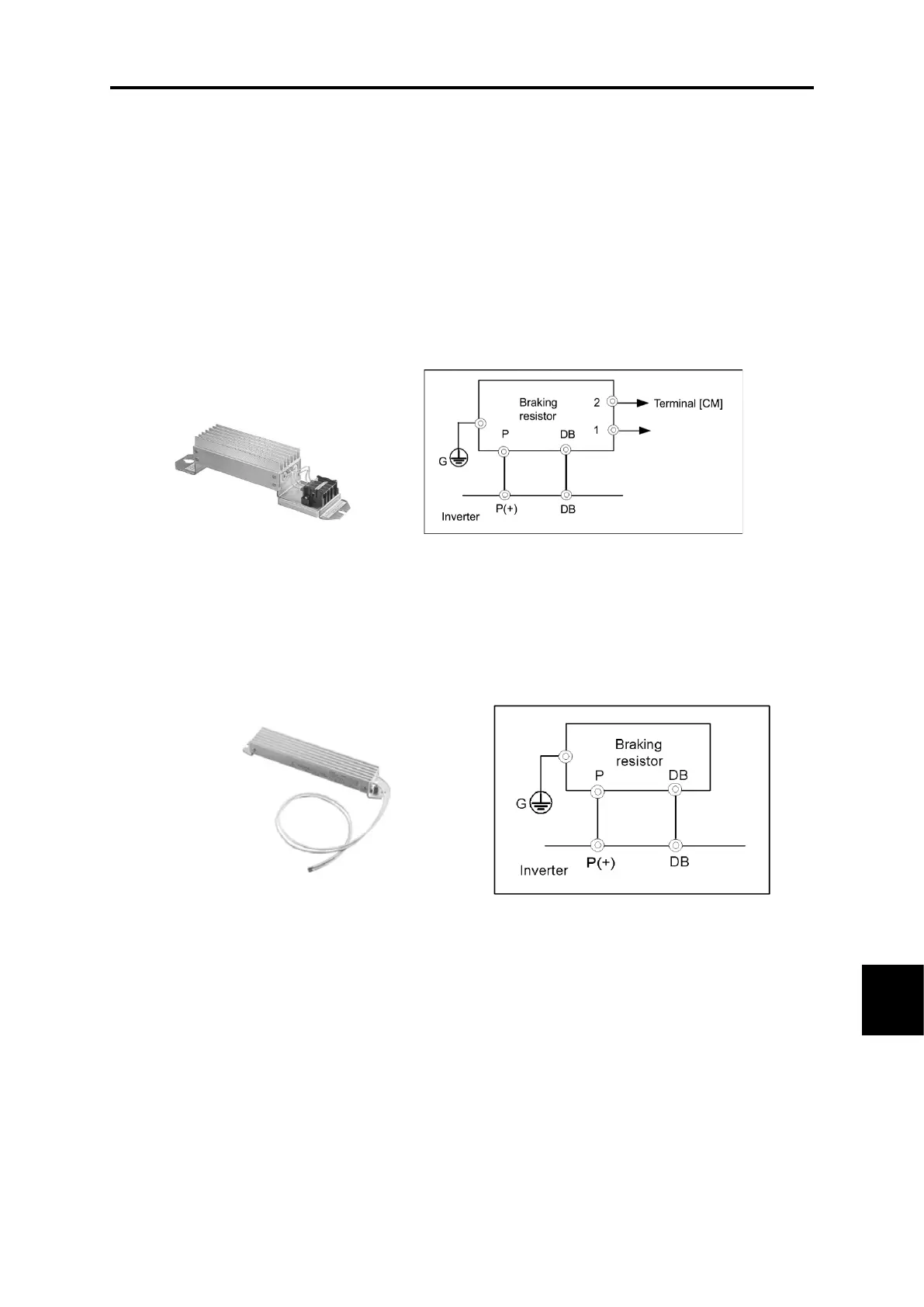

[ 1 ] Standard type

The standard type is equipped with a function for outputting temperature detection signals. To detect temperature

detection signals with FRENIC-MEGA, assign external alarm “THR” to terminal [X1] to [X9], and connect to braking

resistor terminal 2 and terminal 1. Upon detection of the warning signal (preset detection level: 150 °C), the inverter

displays alarm 0H2 on the LED monitor and stops the alarm.

Fig. 11.8-2 Braking resistor (standard type) and connection example

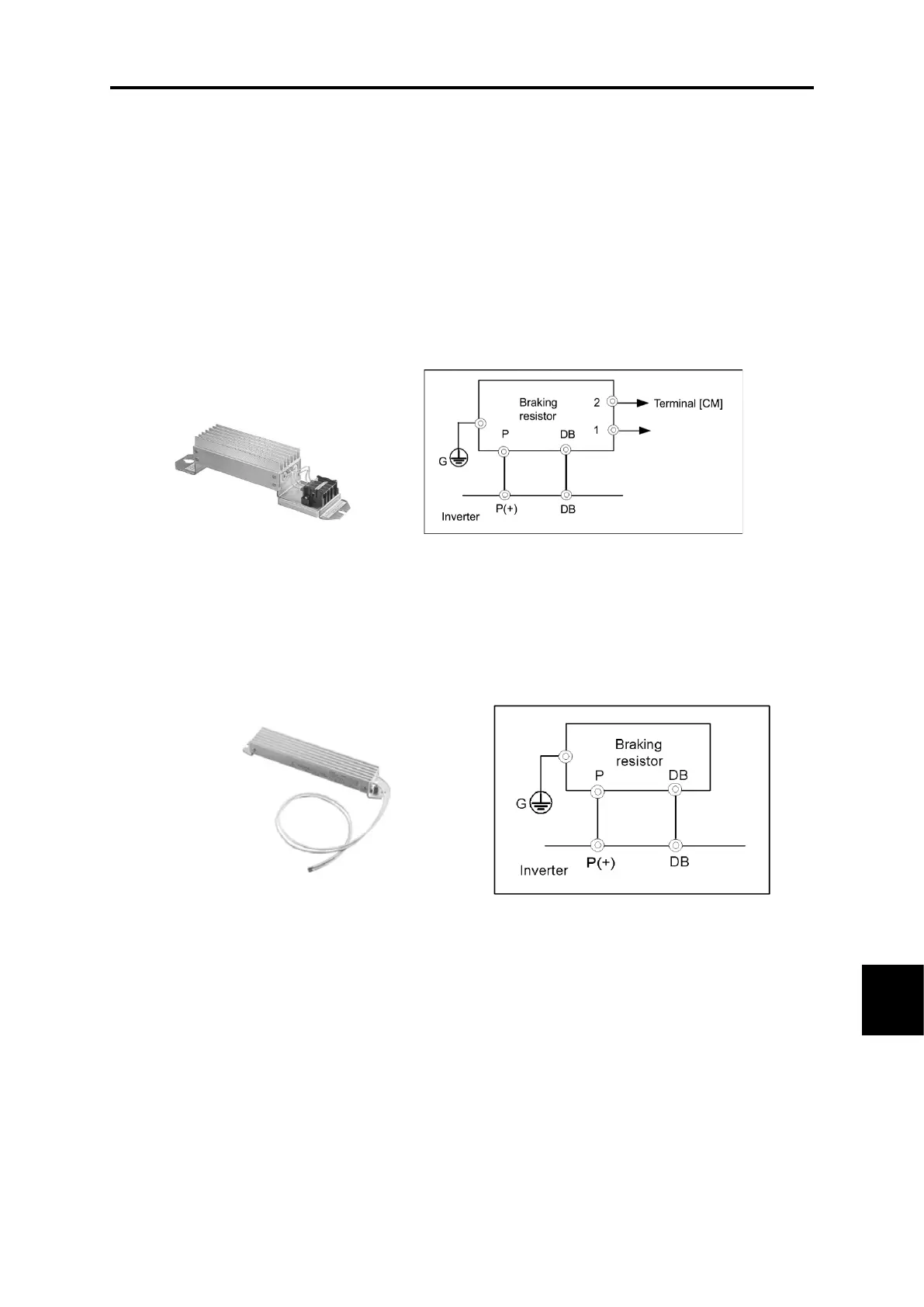

[ 2 ] 10%ED type

The 10%ED type is not equipped with a function for outputting temperature detection signals, and therefore it is

necessary to specify electronic thermal overload relay function (function code F50, F51, F52) settings for braking

resistor protection.

Fig. 11.8-3 Braking resistor (10%ED type) and connection example

For the specifications and external dimensions, refer to “11.8.3 Specification” and “11.8.4 External

dimensions”.

Terminal [X1] to [X9]

(External alarm)

(“THR”)

Loading...

Loading...