11.9 High Power Factor Power Supply Regeneration PWM Converters (RHC Series)

11-29

SELECTING PERIPHERAL EQUIPMENT

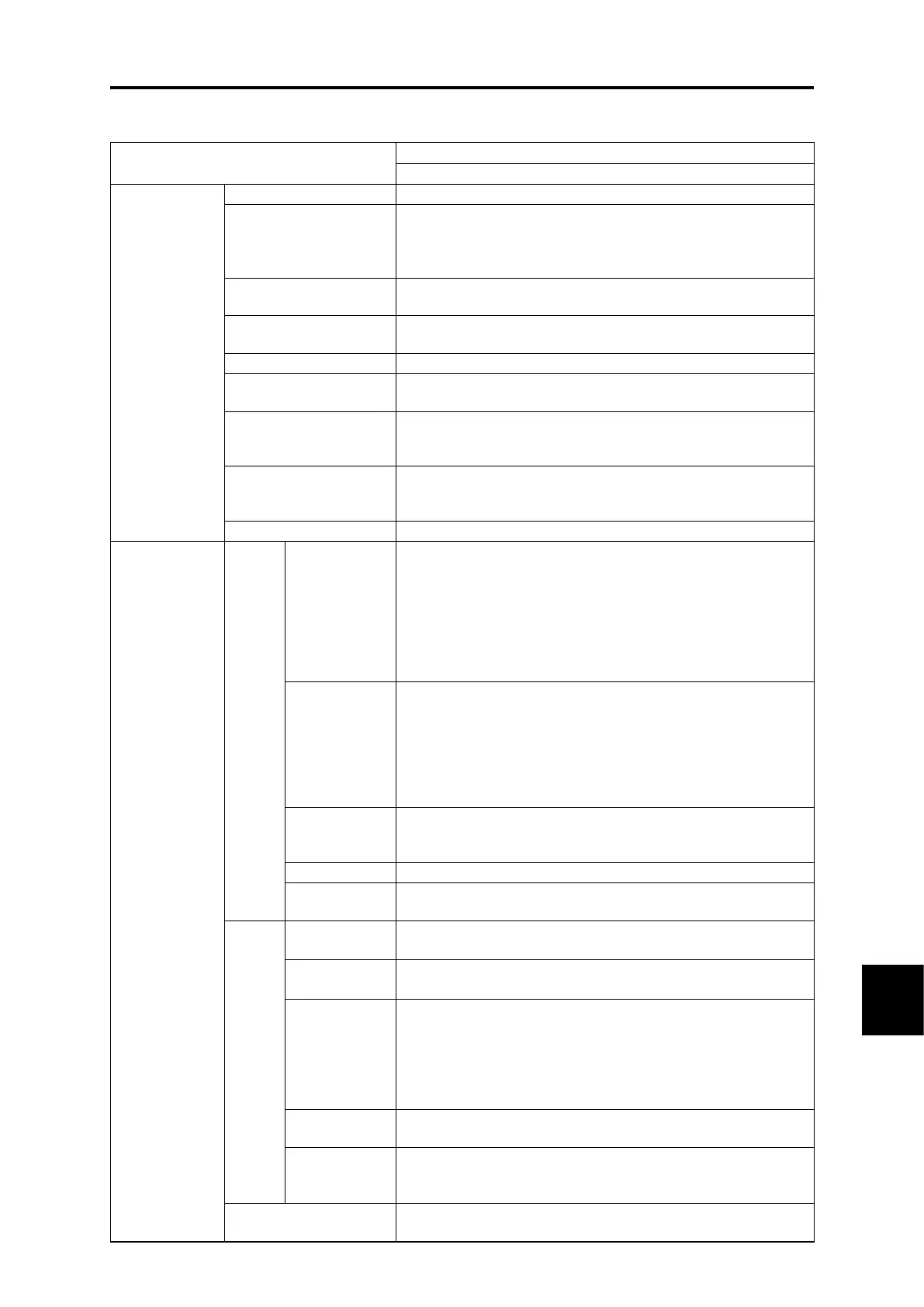

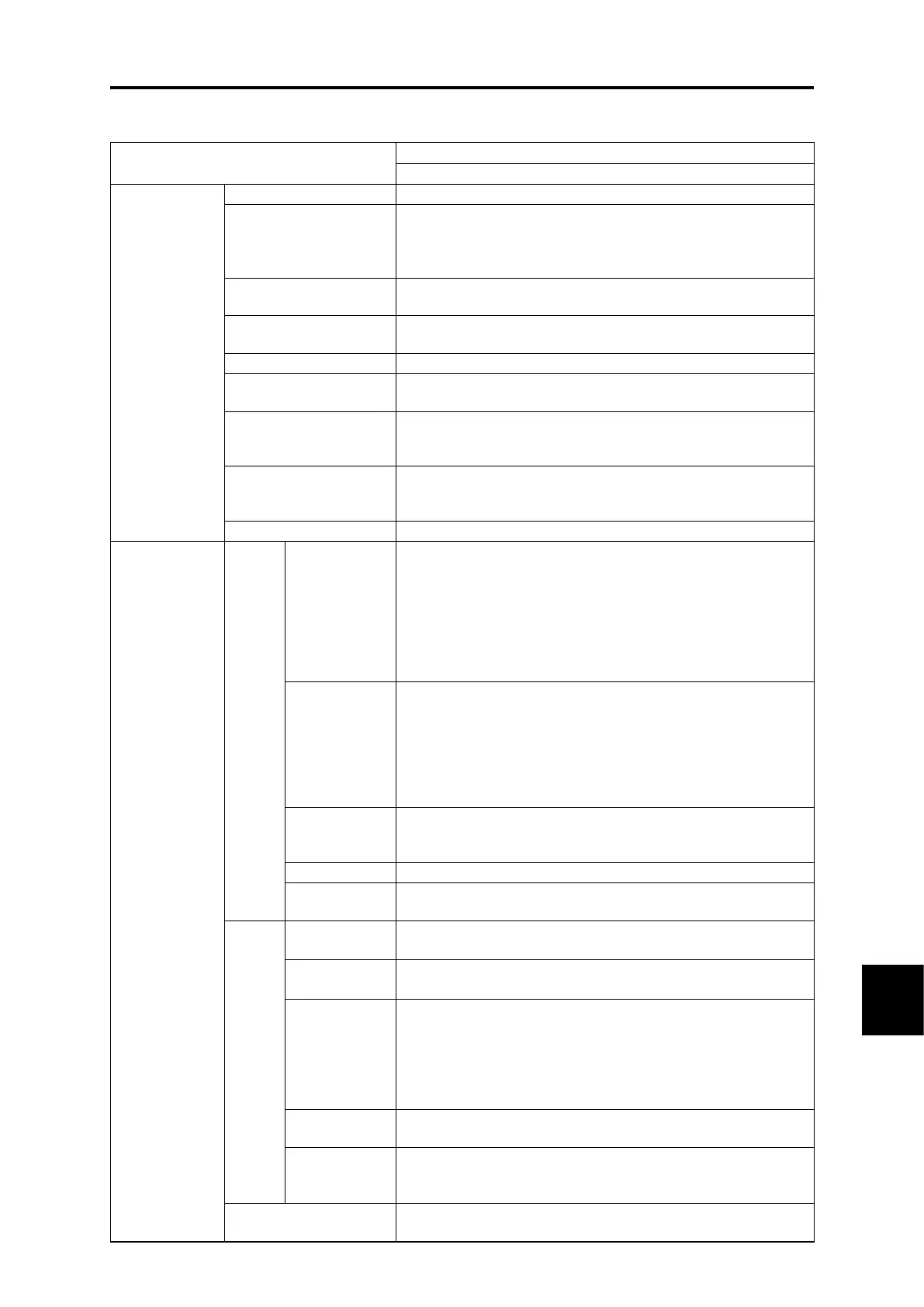

[ 2 ] Common Specifications

By turning the power ON following connection, rectification is performed,

boosting operation is performed with a run command (short

circuit across RUN-CM, or run command via communication),

and the unit is ready for operation.

Running, powering, regenerating, ready for operation, batch

fault, etc.

MD (CT)/LD (VT)

switching

MD (CT): Overload rating of 150% for 1 min, LD (VT): overload

rating of 120% for 1 min selection

2.5 to 15 Hz (see individual specifications for details.)

0.99 or higher (with 100% load, excl. when equipped with OPC-

RHCE-TBSI-□) (*1)

A conversion coefficient of Ki = 0 can be used in accordance

with the harmonic suppression countermeasure guidelines

issued by the Ministry of Economy, Trade and Industry.

Restart after momentary

power failure

When a momentary power failure occurs, the gate is shut off at

the insufficient voltage level, and the converter resumes

operation automatically following recovery.

Control is possible at the previously set limit value or less.

Alarm display

(protective

functions)

AC fuse blown, AC overvoltage, AC undervoltage, AC overcurrent,

AC input current error, input phase loss, synchronous power

supply frequency error, DC fuse blown (*2), DC overvoltage, DC

undervoltage, charging circuit error, fin overheating, external fault,

converter overheating, overload, memory error, touch panel

communication error, CPU error, network equipment error,

operating procedure mistake, A/D converter error, optical network

error, DC fan lock, hardware error, simulation failure

The latest and older alarm codes (up to 10 times), and the latest

and older alarm detailed information (up to 10 times) are saved

and displayed, and the date and time at which alarms occurred

are saved and displayed with the calendar/clock display function

(accuracy: ±27 sec/month (Ta = 25 °C).

Storage period: 5 years or longer (ambient temperature: 25 °C)

* Battery: Built into models of all capacities as standard)

Displays input power, input RMS current value, input RMS

voltage value, intermediate DC current, and power supply

frequency (alarm code).

The load factor can be measured from the keypad.

Function codes can be set and referenced in Japanese, English,

Chinese, and Korean (4 languages).

Sampling data stored in the converter is read and displayed in a graph.

Sampling time: 62.5 us to 1 s

Data is read from the converter in real time and displayed in a graph.

Sampling time: 1 ms to 1 s

Sampling data stored in the converter is read when an alarm

occurs and displayed in a graph.

Sampling time: 62.5 us to 1 s (However, for other than current, the

traceback function can be used with sampling time of 400 us or longer.)

Sampling data is retained in the memory using battery power.

Retention time: 5 years or longer (ambient temperature: 25 °C)

I/O monitoring, system monitoring, and alarm history monitoring,

etc. can be performed.

The function code setting status can be checked.

Function code settings can be edited, transferred, compared,

and initialized.

Lights up while power is being supplied to the converter unit.

Lights up when there is control power.

Loading...

Loading...