5.3 Description of Function Codes 5.3.9 d codes (Applied functions 2)

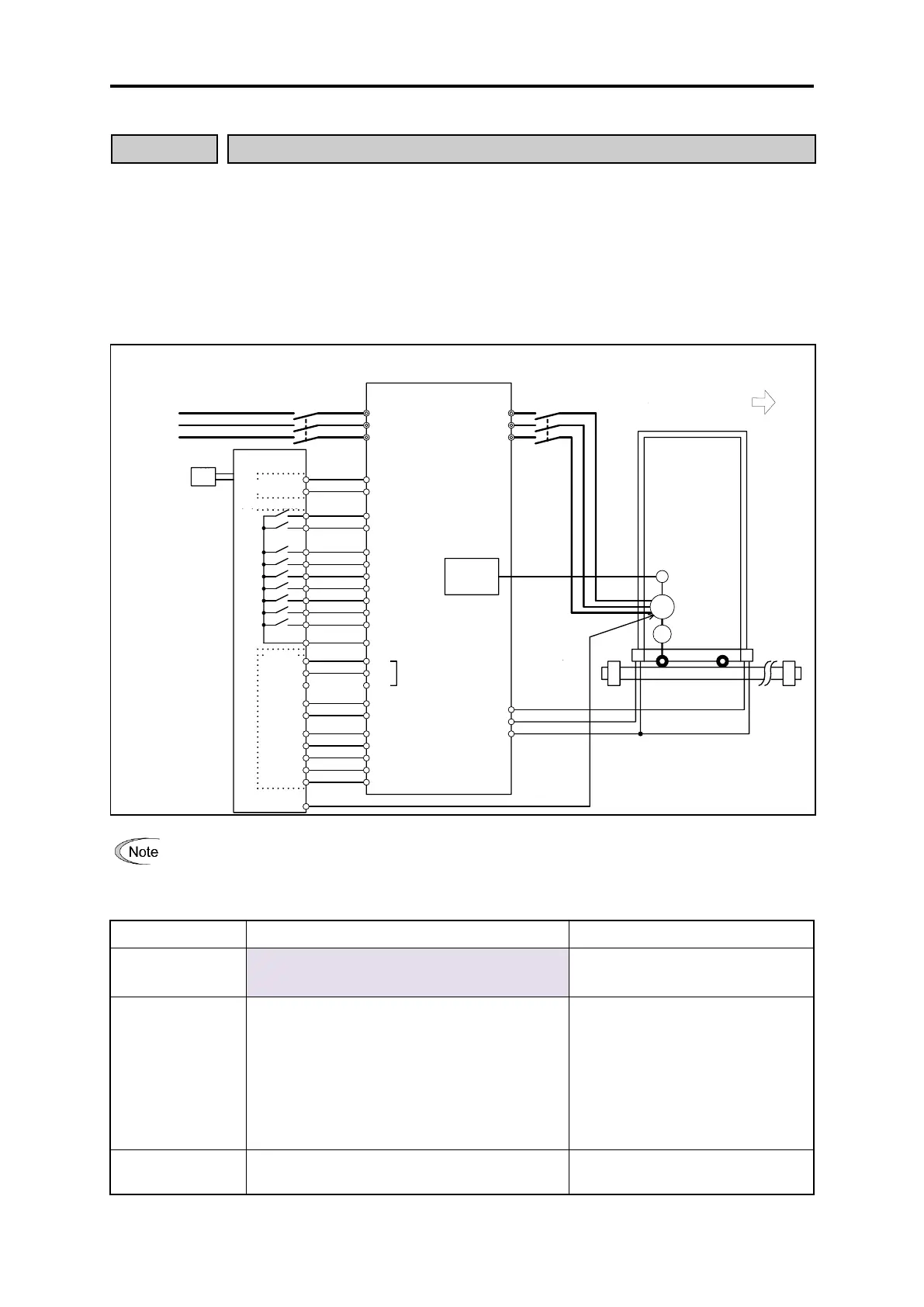

[ 5 ] Position control

Position control can be performed using a feedback signal with PG. Feedback signal pulses are counted at the

inverter, and operation is performed so that the amount of travel is based on the specified position data. Application

is possible under vector control with speed sensor or under V/f control with speed sensor. If performing position

control using a synchronous motor, use an encoder with A-phase, B-phase, Z-phase, and U-phase, V-phase, W-

phase output for the magnetic pole position sensor. With encoders with only an A-phase, B-phase, and Z-phase, it

is not possible to perform position control with a synchronous motor.

An orientation function has also been prepared as a position control response function.

The system configuration is shown in the following diagram.

L1/R

L2/S

L3/T

U

V

W

M

DX+

DX-

RS-485

OPC-PG

PG

OT-(LS) OT+(LS)

30C

30B

30A

X8 (+OT)

X9 (-OT)

CM

FWD

REV

CM

X1 (POS/Hz)

X2 (POS-SET)

X3 (POS-SEL1)

X4 (POS-SEL2)

X5 (POS-SEL3)

X6 (BX)

X7 (TEACH)

CMY

Y1

Y2

Y3

Y4

Y5C

Y5A

FRENIC-MEGA

PG

U

V

W

Do not set direction limit [H08] to 1 or 2 when performing position control. Position control will not function

normally.

The control specifications are shown in the following table.

Vector control with speed sensor: 1:1500

V/f control with speed sensor: 1:200

PG: 1024P/R direct connection

Position control

accuracy

• Motor shaft direct connection:

±1 pulse

• Machine shaft (vector control):

±3 pulses

• Machine shaft (dynamic torque vector control

with speed sensor):

±5 pulses

PG: when 1024P/R used

Control accuracy when multiplying

by 4

Reduction ratio: 1 (excl. gear

backlash)

-99,999,999 to 99,999,999 (user value)

The user value is based on the

electronic gear setting.

Three-phase

AC power supply

Movement direction during

motor forward rotation

RS-485 communication port

Motor

machine brake

operation signal

Loading...

Loading...