6.3 If an Alarm Code Appears on the LED Monitor

6-16

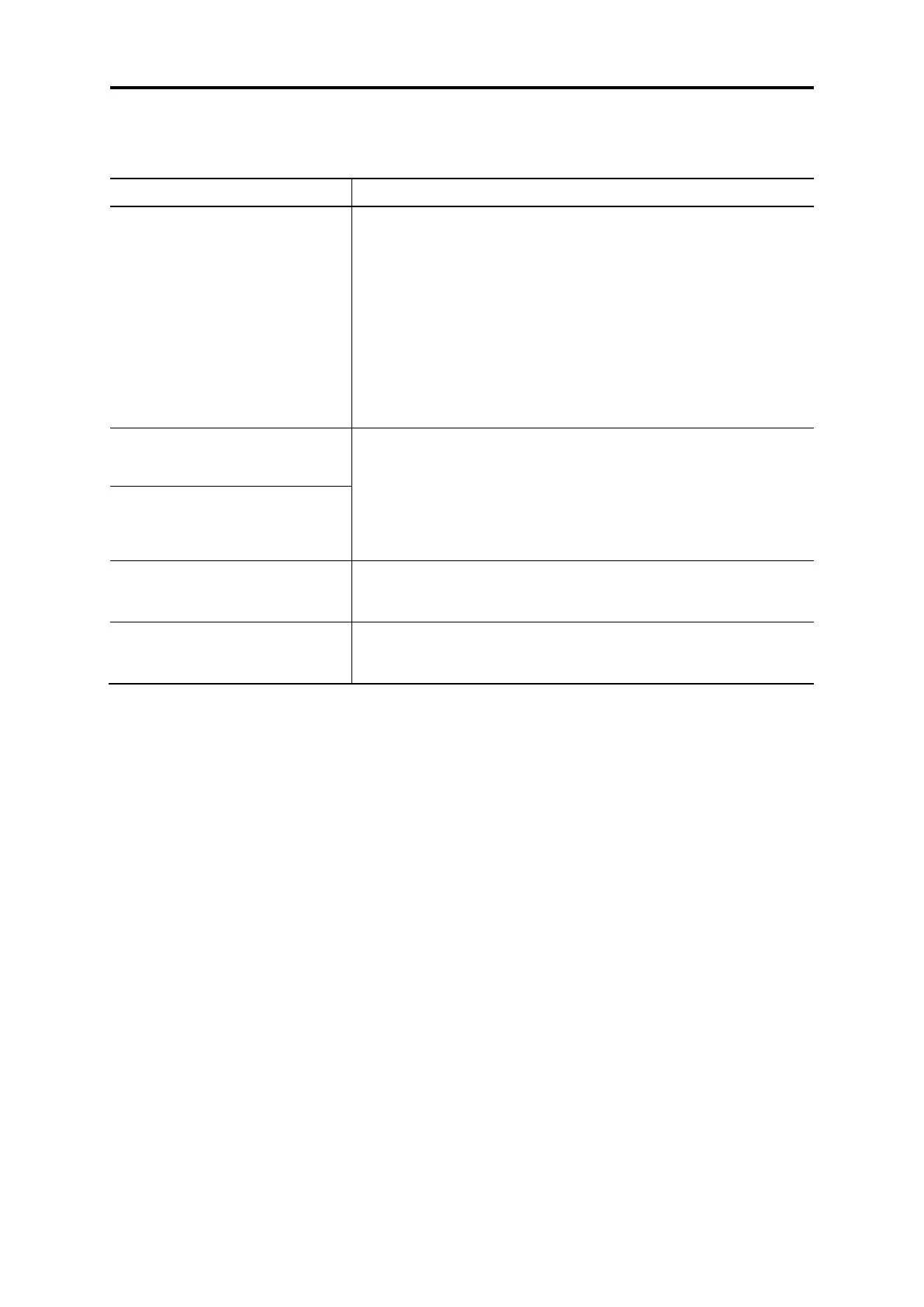

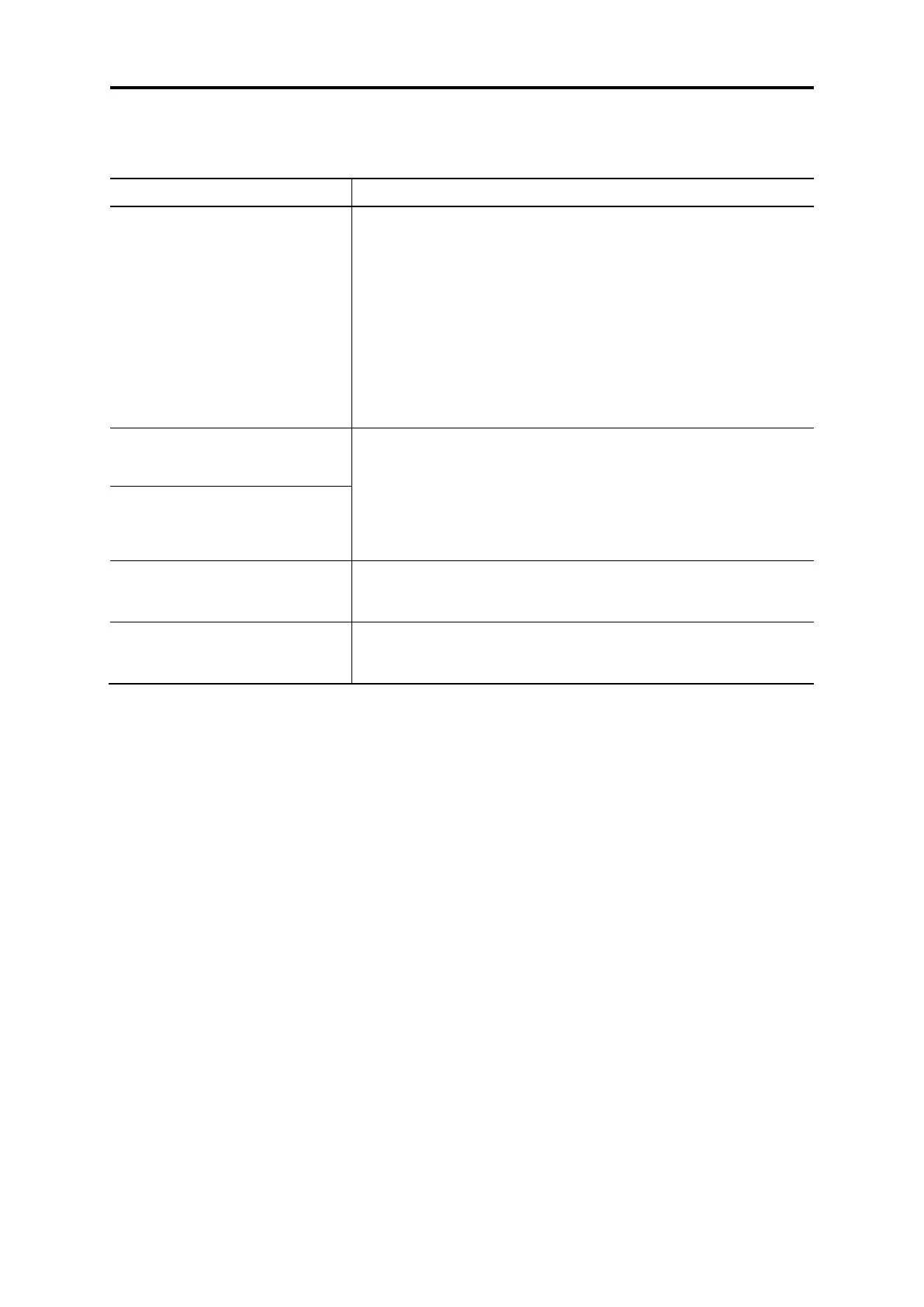

[ 17 ] erC Magnetic pole position detection error

Phenomenon: When performing vector control with sensor (synchronous motors), an error occurred when

performing synchronous motor magnetic pole position detection.

(1) The inverter settings are not

appropriate.

Check whether the motor being used, the existence and type of the

speed/magnetic pole position sensor, the control method (F42*) and

feedback pulse input method (d14), and the feedback pulse count (d15)

are consistent.

➔ Check the machine configuration (motor speed/magnetic pole

position sensor type and specifications), and set F42*, d14, and d15

correctly.

Ensure that the magnetic pole position detection method selection

(P30*) has been set to either “0” or “3”, and that the magnetic pole

position sensor offset (P95*) is not “999 (offset not adjusted)”.

➔ Set P95* correctly. (Auto tuning is also possible.

See “4.7.2 [3] Synchronous motor tuning method”.)

(2) There is a problem with the

speed/magnetic pole position

sensor connection.

Check for speed/magnetic pole position sensor output wiring contact

defects, and check the AB phase or UVW phase sequence.

➔ Connect the feedback input option card and speed/magnetic pole

position sensor correctly.

Check for motor wiring contact defects, and check the phase

sequence.

➔ Connect the motor correctly to the inverter.

(3) The motor rotation direction and

sensor output do not match.

(4) There is a problem with the

option card connection.

Check whether the connector on the option card is properly engaged

with that of the inverter.

➔ Reinsert the option card into the inverter.

(5) The inverter was affected by

strong electrical noise.

Check noise countermeasures (grounding condition, signal line and

communication cable/main circuit wiring installation method, etc.)

➔ Take noise countermeasures.

The explanations for function codes with an asterisk (*) are limited to motor 1. If using motor 2 to 4, replace

with the relevant function codes in Chapter 5 "Table 5.3-21 Function codes to be switched".

Loading...

Loading...