-93-

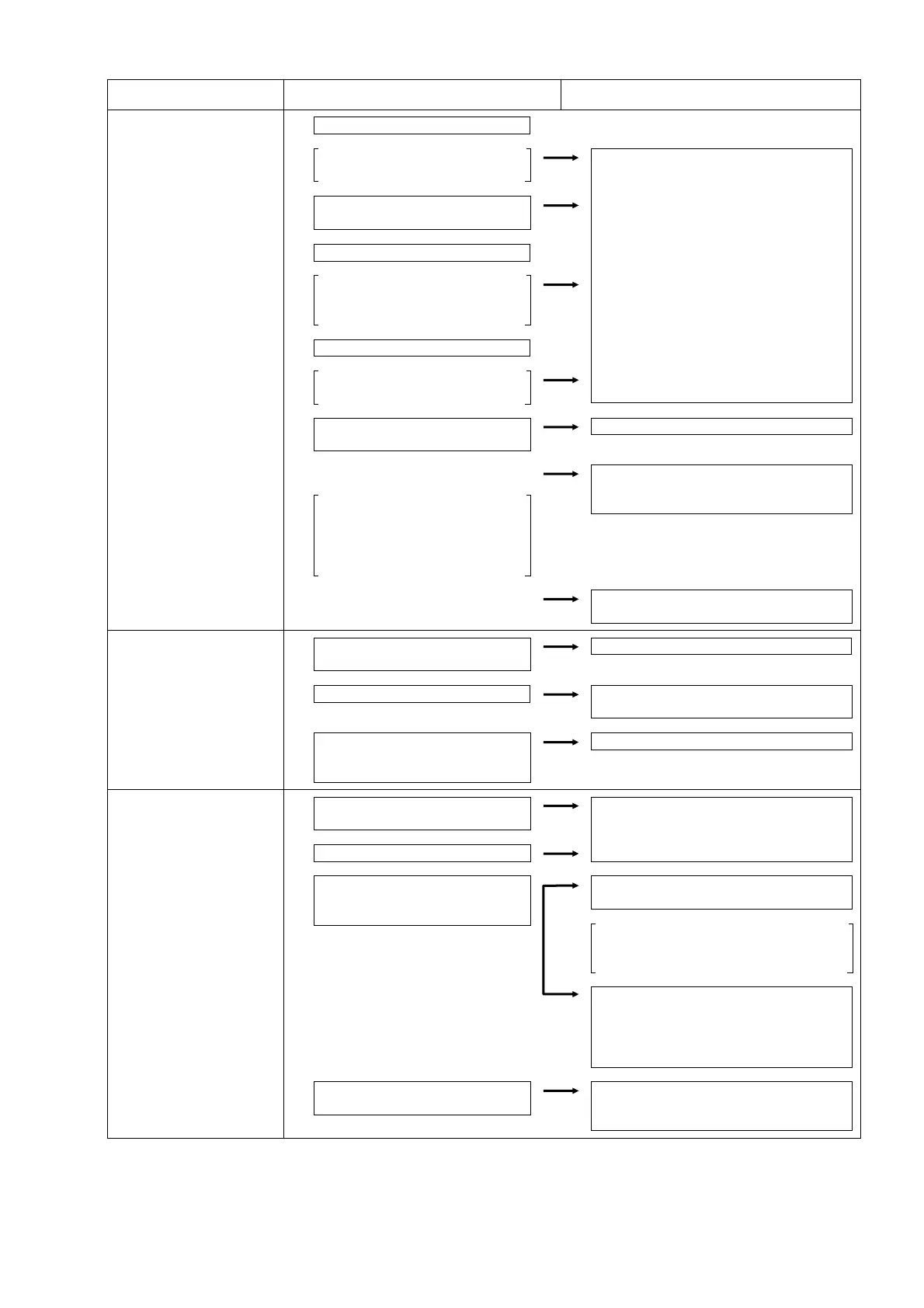

Status Probable cause Troubleshooting

(Continued from the

previous page.)

High turbidity

Turbidity is higher than those of

sewage and return sludge.

Move sensor to a place of smaller

diameter on the same pipeline.

Move the sensor to other places or to

different piping.

Pipe is old and scale is attached

on inside.

Lining is thick.

Because of mortar lining or the

like, thickness is tens mm or

more.

Lining is peeled.

There is a gap between the lining

and the pipe.

Sensor is mounted on bend pipe

or tapered pipe.

Mount the sensor on straight pipe.

3. Effect of external noise

Reduce the length of main unit

sensor cable to a minimum.

Ground the main unit and piping.

There is a radio broadcasting

station nearby.

Measurement conducted near

a passage of vehicles or

electric cars.

4. Hard failure

Refer to “6.5.7. Remedying a hardware

fault”.

Measured value not zero

when fluid stops flowing.

Fluid forms a convection inside

the pipe.

Normal

Zero point adjustment

Readjust the zero point after fluid has

completely stopped flowing.

Pipe is not completely filled or is

empty when water is at a

standstill (LED lit red).

Normal

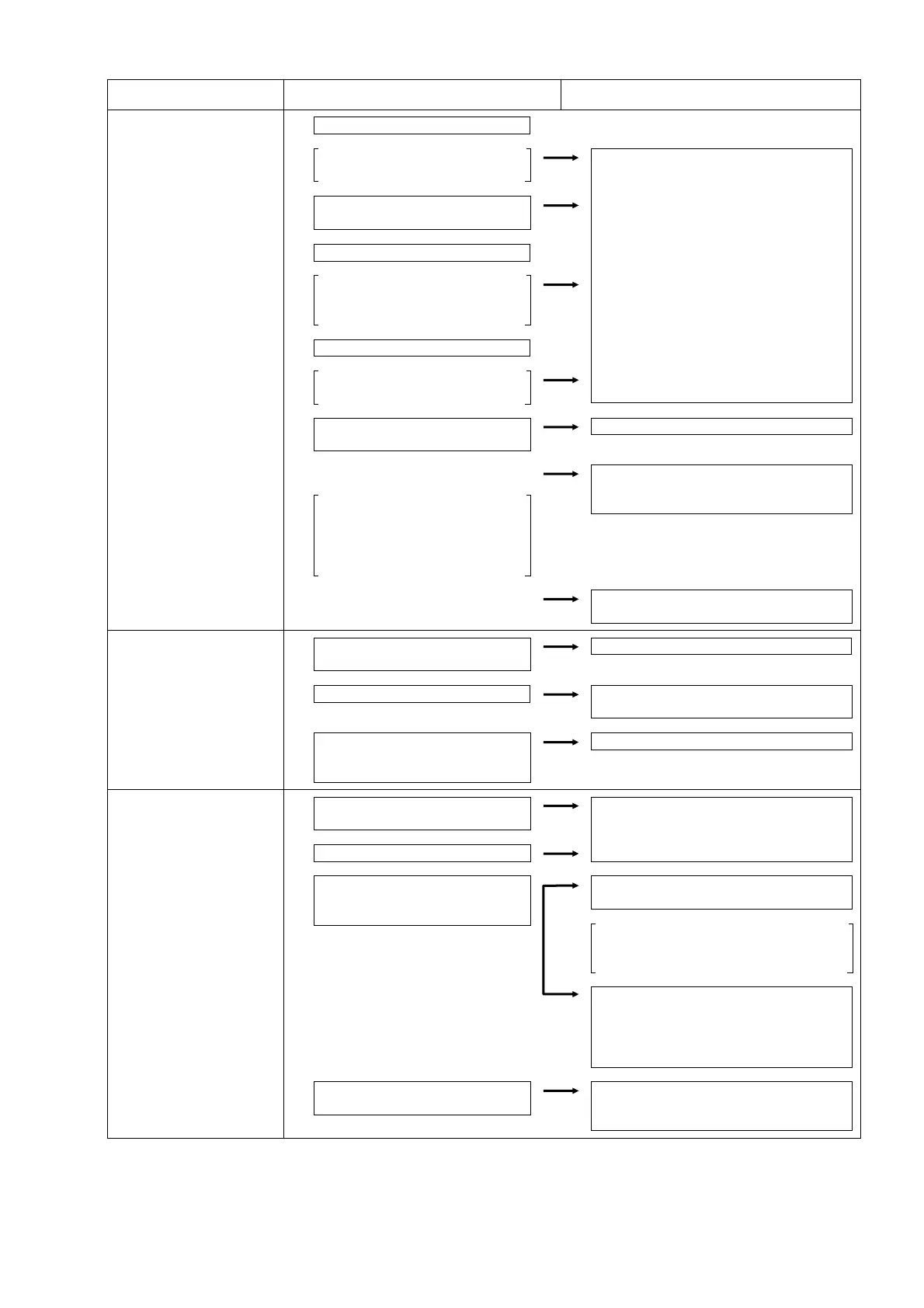

Error in measured value

Input piping specifications differ

from the actual ones.

A difference of 1% in inner diameter

causes an error of about 3%.

Input the correct specifications.

Input scale as lining.

Scales exist on wall of old pipe.

Insufficient linear pipe length

(10D or more for upstream and

50D or more for downstream)

Find another mounting place (upstream

of disturbing objects).

No disturbing objects in flow within 30D

upstream without pump, valve,

combined pipe, etc.

Mount the sensor at different angles

with respect to the cross section of

pipe to fine the location where mean

value is obtainable. The mount the

sensor at that location.

Pipe is not filled with fluid or

sludge is deposited in the pipe.

Occurs particularly where sectional

area is small.

Move sensor to a vertical pipe.

Loading...

Loading...