PREVENTIVE MAINTENANCE

General

The required maintenance interval will depend largely on the quality of the media used and how often the

machine is used. The maintenance interval must be determined on an individual basis. We recommend

that the specified maintenance work be completed at the specified intervals. We also recommend a

function check be completed once or twice per year.

Maintenance must only be done by authorized personnel.

The machine is connected to the electricity supply and some components are live.

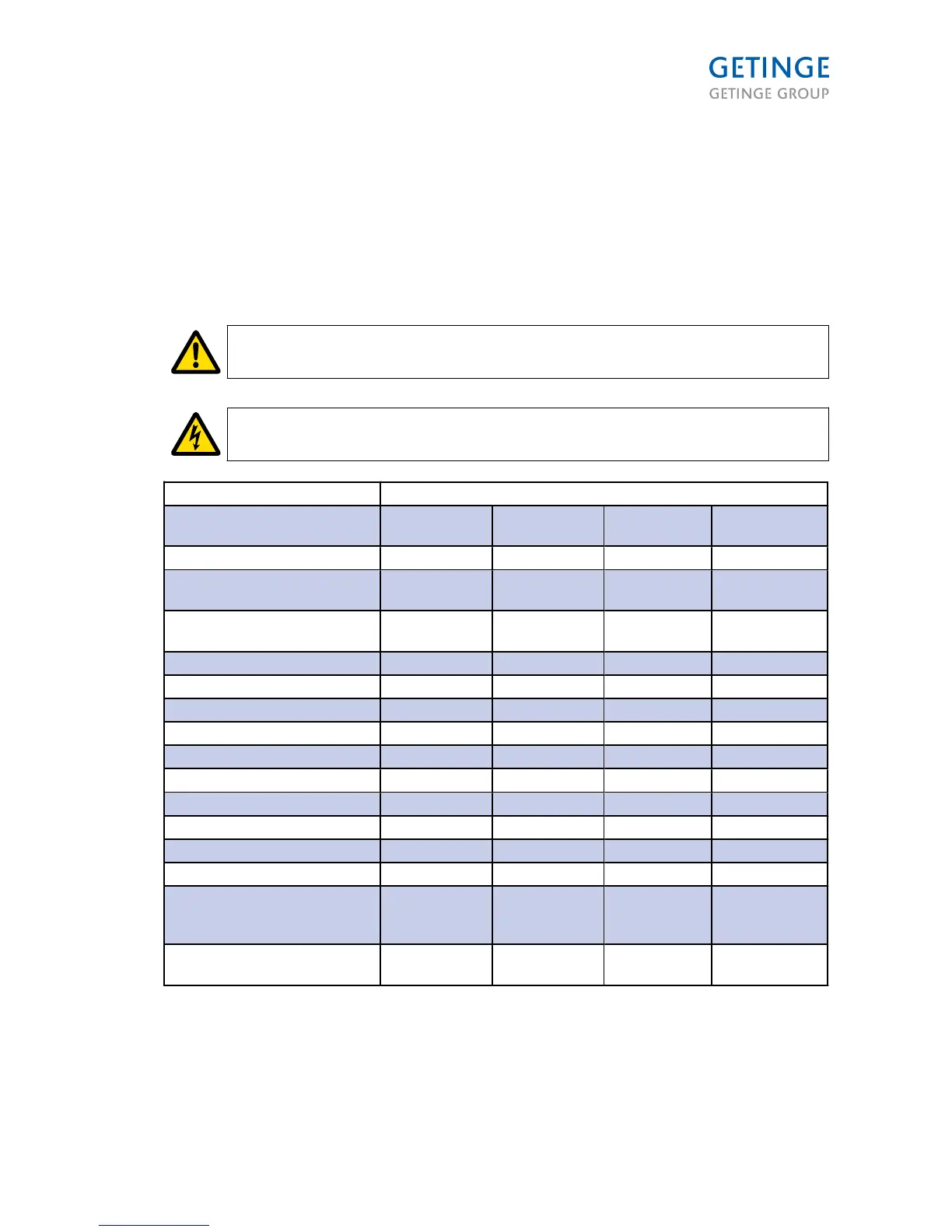

Component Interval

Check yearly Replace if

necessary

Replace yearly Replace every

second year

Door seal • •

Hoses between dosing pump

and detergent container

• •

Hose between dosing pump and

machine

• •

Hose in dosing pump • •

Bearing in wash arms • •

Sterile filter in the dryer • • •

Hoses to dryer • • •

Hoses to waste pump and tanks • •

Electrical connections •

Crush protection •

Safety line •

Instrumentation •

Emergency stop button •

Check that the electrical cables

are correctly connected to the

outlet.

•

Fan filter on the electrical

cabinet.

• •

In places where items can be soiled with gravel or sand, an extra weekly cleaning of the machine sump is

recommended. A wet-vac can be used for cleaning the sump.

Page 121 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Loading...

Loading...