ENGINEERING MANUAL OF AUTOMATIC CONTROL

PNEUMATIC CONTROL FUNDAMENTALS

90

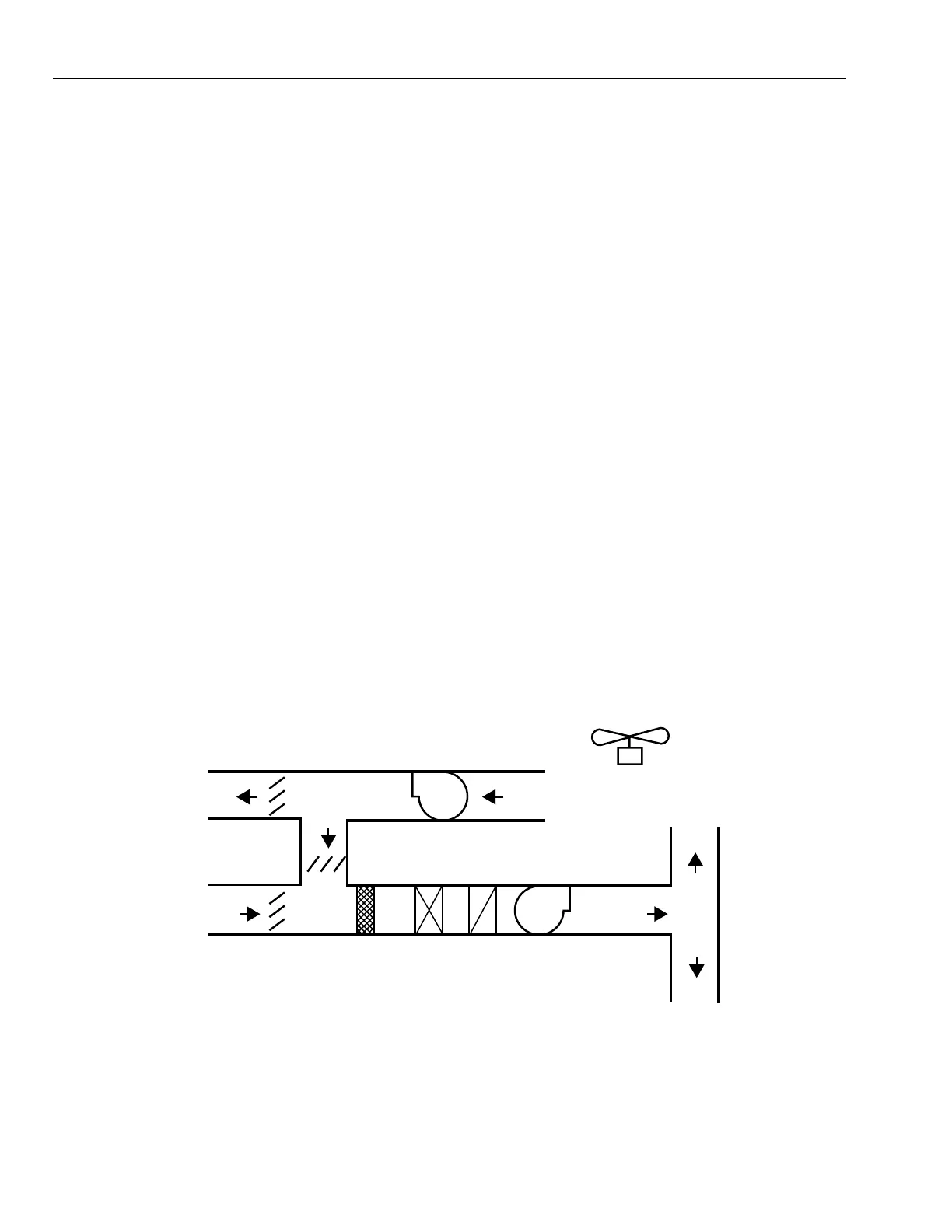

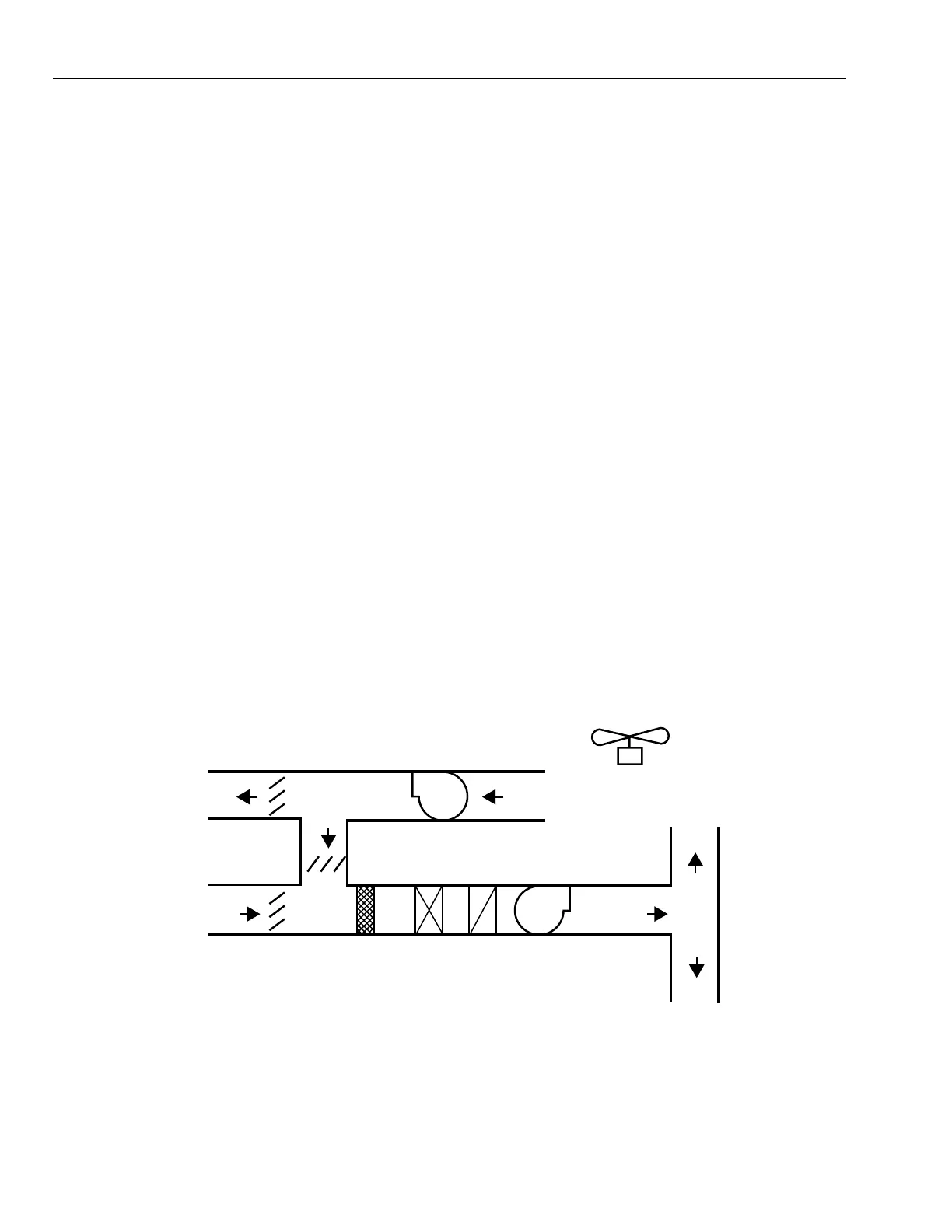

PNEUMATIC CONTROL SYSTEM EXAMPLE

The following is an example of a typical air handling system

(Fig. 74) with a pneumatic control system. The control system

is presented in the following seven control sequences (Fig. 75

through 79):

— Start-Stop Control Sequence.

— Supply Fan Control Sequence.

— Return Fan Control Sequence.

— Warm-Up/Heating Coil Control Sequence.

— Mixing Damper Control Sequence.

— Discharge Air Temperature Control Sequence.

— Off/Failure Mode Control Sequence.

Controls are based upon the following system information

and control requirements:

System Information:

— VAV air handling system.

— Return fan.

— 16.5 m

3

/s.

— 1.9 m

3

/s outside air.

— 1.4 m

3

/s exhaust air.

— Variable speed drives.

— Hot water coil for morning warm-up and to prevent

discharge air from getting too cold in winter .

— Chilled water coil.

— Fan powered perimeter VAV boxes with hot water reheat.

— Interior VAV boxes.

— Water-side economizer.

— 8:00 A.M. to 5:00 P.M. normal occupancy.

— Some after-hour operation.

GRAVITY

RELIEF

RETURN

AIR

RETURN FAN

SUPPLY FAN

EAST

ZONE

DISCHARGE

AIR

WEST

ZONE

MIXED

AIR

OUTSIDE

AIR

EXHAUST

M10298

Control Requirements:

— Maintain design outside air airflow during all levels of

supply fan loading during occupied periods.

— Use normally open two-way valves so system can heat

or cool upon compressed air failure by manually running

pumps and adjusting water temperatures.

— Provide exhaust/ventilation during after-hour occupied

periods.

— Return fan sized for 16.5 m

3

/s.

START-STOP CONTROL SEQUENCE

Fans 1M through 3M (Fig. 75) operate automatically subject

to starter-mounted Hand-Off-Automatic Switches.

The Supply Fan 1M is started and controls are energized by

Electric-Pneumatic Relay 2EP at 0645 by one of the following:

— An Early Start Time Clock 1TC

— A drop in perimeter space temperature to 18°C at Night

Thermostat TN

— An after-hour occupant setting the Spring-Wound Interval

Timer for 0 to 60 minutes.

The Supply Fan 1M operation is subject to manually reset

safety devices including Supply and Return Air Smoke

Detectors; a heating coil, leaving air, Low Temperature

Thermostat; and a supply fan discharge, duct High Static

Pressure Cut-Out.

Fig. 74. Typical Air Handling System.

Loading...

Loading...