ENGINEERING MANUAL OF AUTOMATIC CONTROL

CHILLER, BOILER, AND DISTRIBUTION SYSTEM CONTROL APPLICATIONS

346

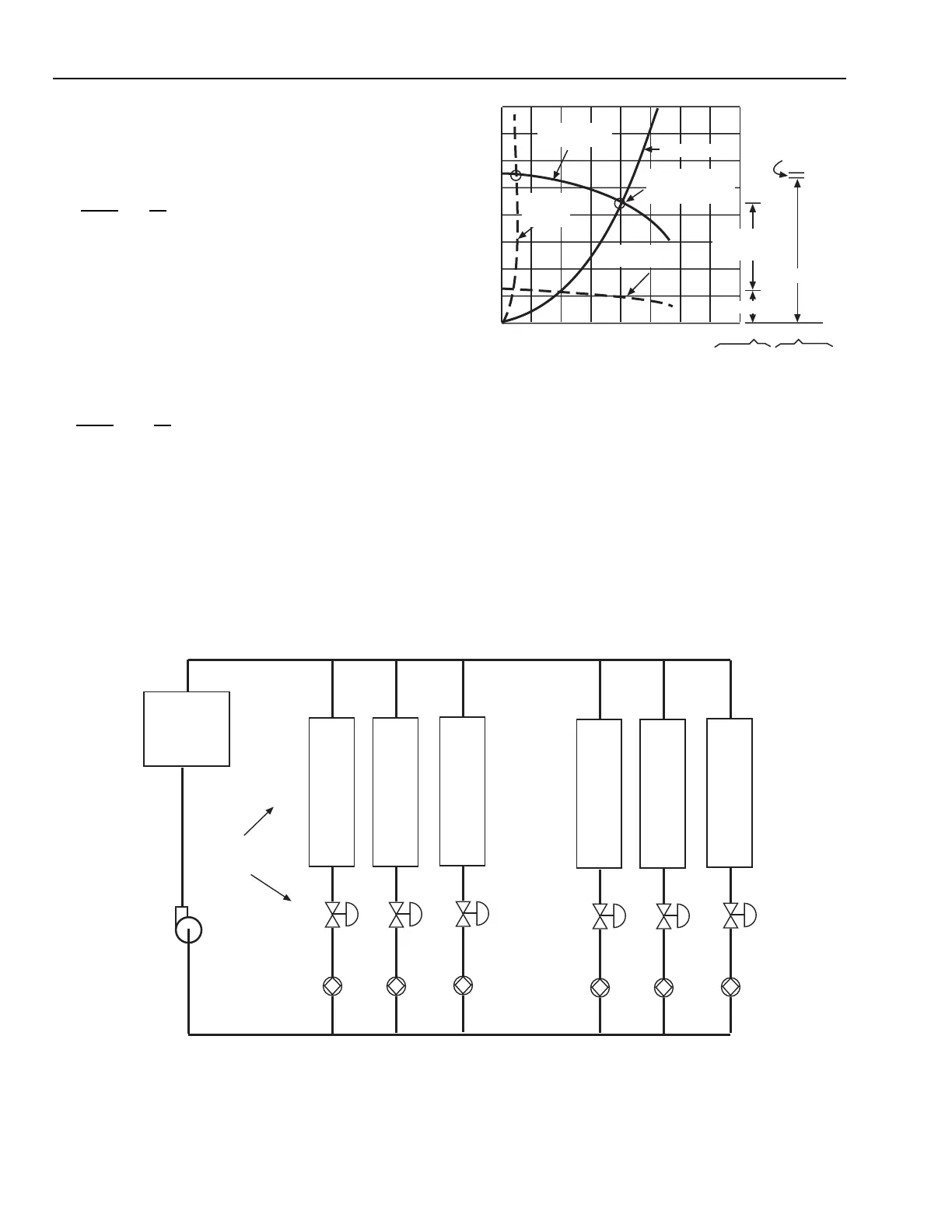

As flow through the system is reduced, a new system curve

is established. See the 0.375 L/s curve in Figure 69. When the

flow is reduced, the new pressure loss in source and supply and

return piping can be calculated using the formula:

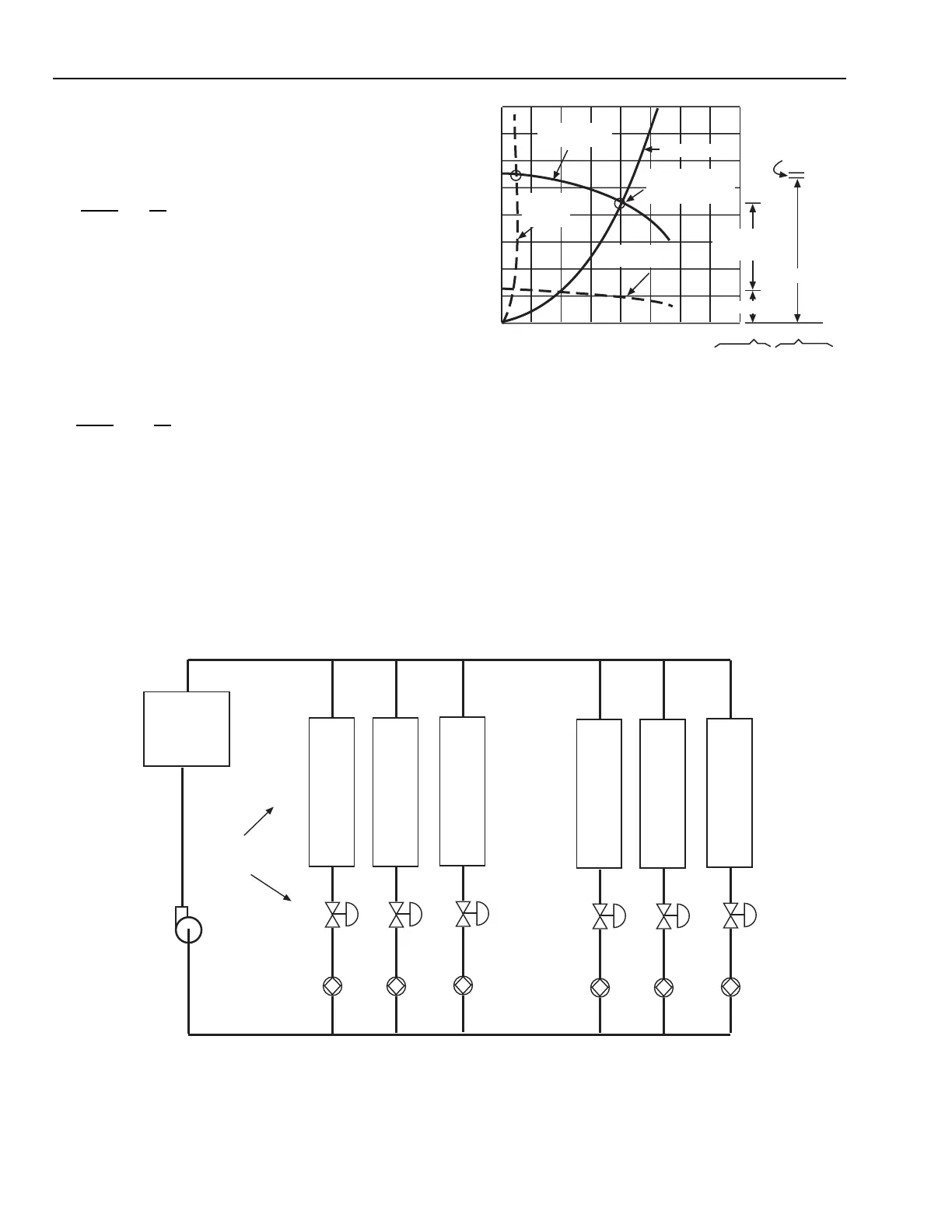

Fig. 70. Direct Return Piping System

Where:

flow

1

= present flow

flow

2

= next flow

p

1

= present pressure drop

p

2

= next pressure drop

For example: If flow

1

= 2.5 L/s, flow

2

= 0.375 L/s, and p

1

=

99 kPa, then p

2

= 2.2 kPa.

p

2

= 99 x 0.0225

= 2.2 kPa

At low flow, the pressure drops through the coils, coil piping,

and heat source tend to disappear and nearly all of the now

elevated pump pressure appears across the partially closed

valves V1, V2, and V3. This can cause valve noise, poor control,

or failure of valves to seat. Control solutions are discussed in

following sections.

Fig. 69. System and Pump Curves for a

Closed System at Various Loads.

DIRECT VS REVERSE RETURN PIPING SYSTEMS

Distribution system control solutions vary dependent upon

whether the designer chose a direct or reverse return piping system.

Systems are sometimes configured as a combination of both; a

high-rise building could, for example be reverse return on the

riser and direct return on the floor run-outs. Direct return systems

are usually lower cost and used in smaller installations. Reverse

return systems are used in both small and large installations.

flow

2

flow

1

2

=

p

2

p

1

()

0.375

2.5

2

=

p

2

99

PUMP CURVE

AT 817 RPM

PUMP 1750 RPM

CURVE

C4604

SYSTEM CURVE

SYSTEM

CURVE

AT 0.375 L/s

OPERATING POINT

AT DESIGN OF

2.5 L/s

COIL,

SUPPLY/RETURN

PIPING 99 kPa

COIL,

SUPPLY/

RETURN

PIPING 2.2 kPa

VALVE162 kPa

VALVE 33 kPa

54.3753.753.1252.51.8751.250.6250

L/s

DESIGN

CONIDITION

50% LOAD

CONDITION

0

30

60

90

120

150

180

210

240

PRESSURE (kPa)

3 kPa

RETURN

HEAT/

COOL

COIL

1

V1

B1

HEAT/

COOL

COIL

2

V2

B2

HEAT/

COOL

COIL

3

V3

B3

HEAT/

COOL

COIL

4

V4

B4

HEAT/

COOL

COIL

5

V5

B5

HEAT/

COOL

COIL

6

V6

B6

PUMP

75 L/s

143 kPa

HEAT

EXCHANGER

36 kPa

DROP

12.5 L/S

PER

AHU COIL

3 kPa

DROP

3 kPa

DROP

6 kPa

DROP

3 kPa

DROP

3 kPa

DROP

12 kPa

DROP

SUPPLY

24 kPa

DROP

24 kPa

DROP

DESIGN DROPS,

ALL COILS &

VALVES

36 kPa

DROP

3 kPa

DROP

3 kPa

DROP

6 kPa

DROP

3 kPa

DROP DROP

12 kPa

DROP

30 kPa

DROP

24 kPa

DROP

12 kPa

DROP

6 kPa

DROP

0 kPa

DROP

M15283

Loading...

Loading...