INDIVIDUAL ROOM CONTROL APPLICATIONS

ENGINEERING MANUAL OF AUTOMATIC CONTROL

419

TWO-PIPE HEATING/COOLING

The flow of medium thr ough a f an coil unit can be contr olled

in two ways. One method uses a tw o-way valve to contr ol the

flow of steam or hot or c hilled water. The second method , shown

in Figure 31, uses a thr ee-way valve to contr ol hot or c hilled

water f low.

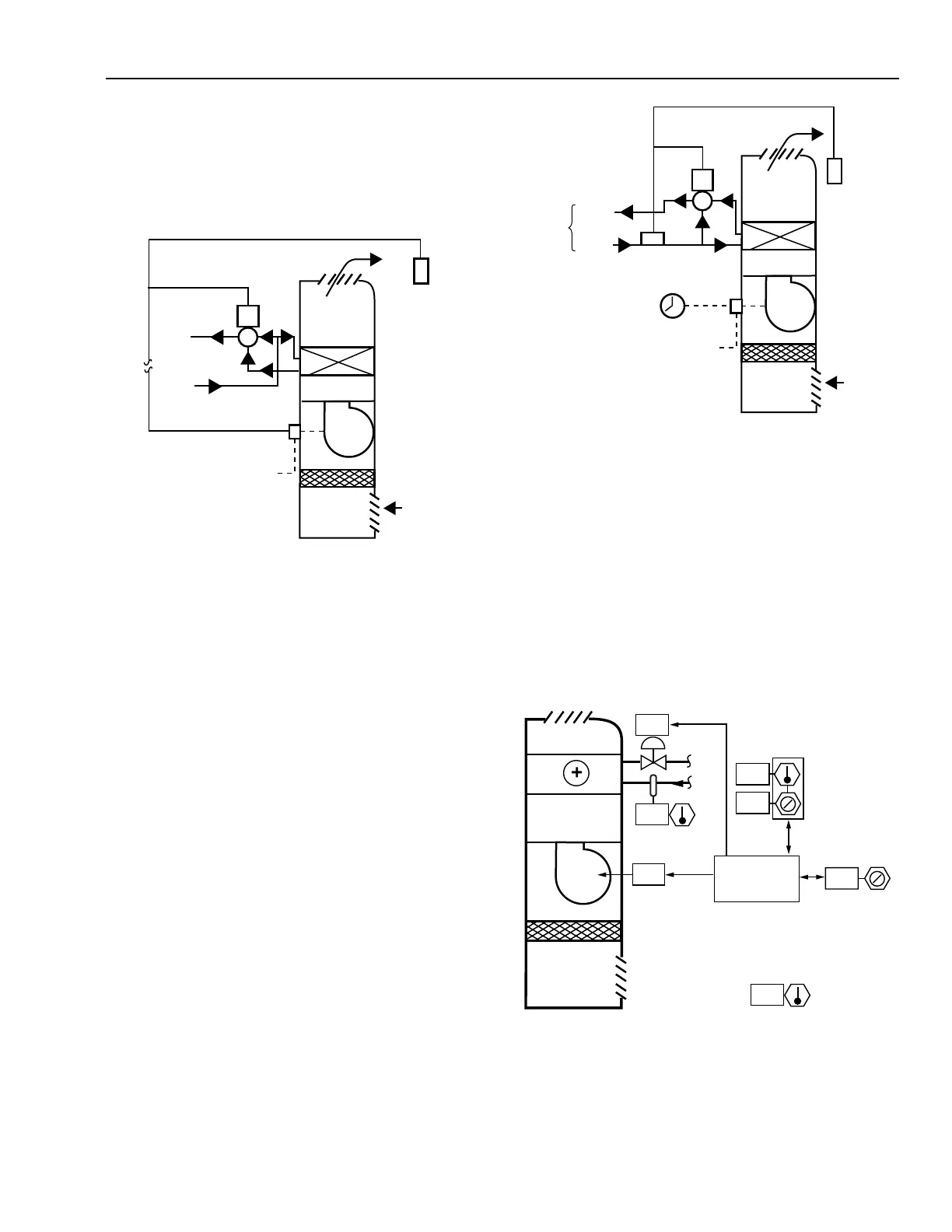

Fig. 32. Two-Pipe Heating/Cooling Fan Coil Unit.

The r oom ther mosta t opens the coil v alve on a fall in space

temper atur e dur ing the hea ting cycle. In the cooling c ycle,

chilled water in the pipes causes the pipe-mounted sensor to

reverse the ther mosta t action and the ther mosta t opens the v alve

as space temper atur e rises. The fan can be oper ated fr om a local

switch or a central time clock.

The surf ace ar ea of the coil is lar ge to accommoda te cooling

requir ements. Therefore, when a single coil is used f or both

heating and cooling , the hot w ater suppl y temper atur e should

be lower. Typical hot w ater suppl y temper atur es range between

32 and 60 °C.

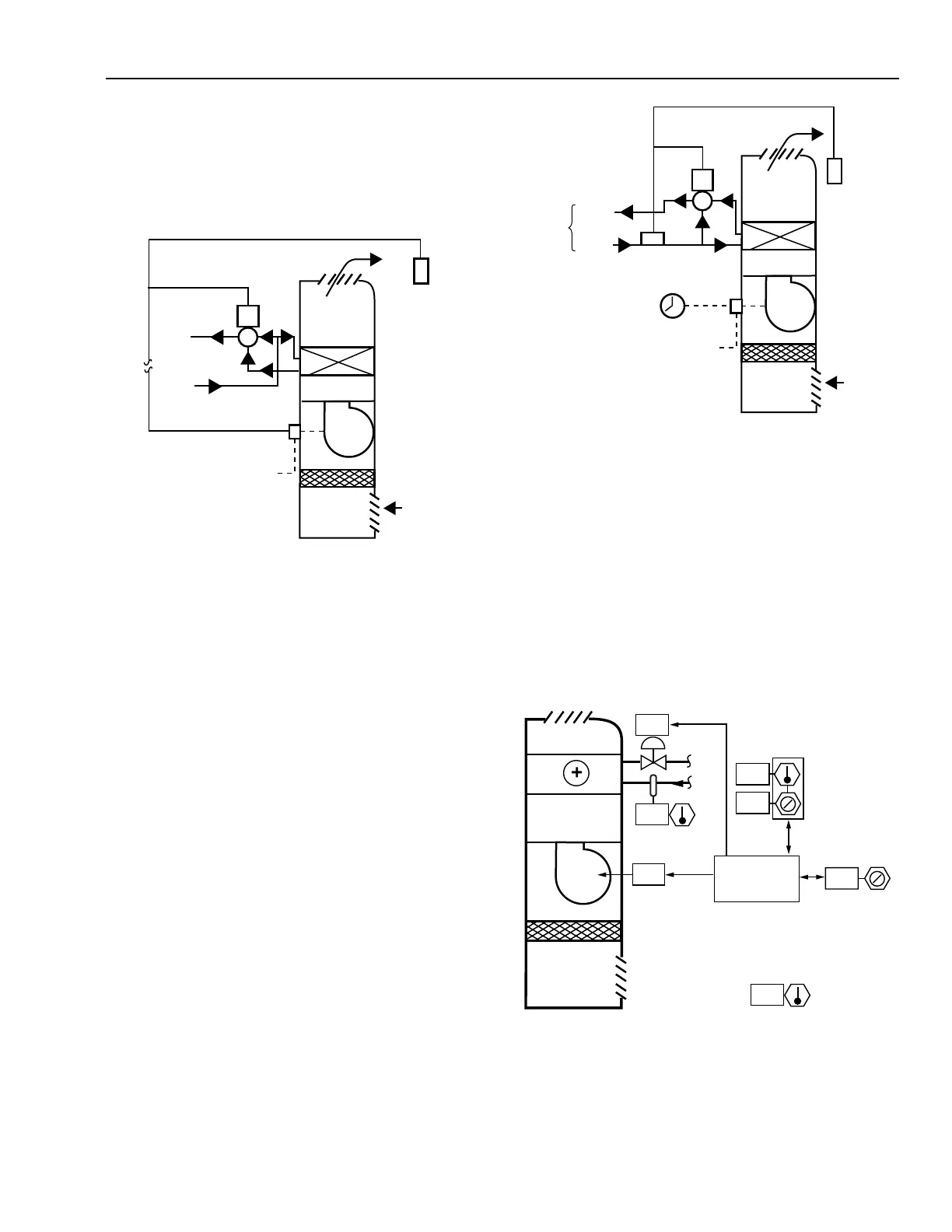

Fig. 31. Two-Pipe Heating Fan Coil Unit

Using Three-Way Mixing Valve.

The thr ee-way valve provides constant f low in the suppl y

and r etur n lines and minimiz es pr essur e fluctua tions a t the v alve.

A modula ting ther mosta t contr ols the thr ee-way valve to

regulate water f low thr ough the coil. In a hea ting a pplica tion,

when the ther mosta t senses space temper atur e below the

ther mosta t setpoint, the valve is positioned to allo w full flow

thr ough the coil. As space temper atur e rises, the ther mosta t

contr ol signal modula tes the v alve to decr ease the amount of

flow thr ough the coil and incr ease the b ypass flow around the

coil. At the upper end of the ther mosta t thr ottling r ange, the

valve is in the coil b ypass position, elimina ting flow thr ough

the coil. The fan r uns contin uously or is stopped as space

temper atur e rises above setpoint. Cooling-onl y systems oper ate

in a similar w ay.

TWO-PIPE HEATING/COOLING, SINGLE COIL

Figur e 32 shows a two-pipe fan coil a pplication tha t uses a

single coil for hea ting and cooling with seasonal c hang eover.

Control for this application requires a heating/cooling room

ther mosta t tha t r everses its action fr om a r emote hea ting/cooling

chang eover signal. One method of automa tic chang eover is to

install a pipe-mounted sensor that switches thermostat action

when it senses a change in supply medium between hot and

chilled water. Because it cannot of fer sim ultaneous hea ting and

cooling capability, this system can cause pr oblems dur ing

inter media te seasons w hen hot w ater is in the system and

cooling is needed , or vice versa.

C3033

DISCHARGE

AIR

THERMOSTAT

RETURN

AIR

FILTER

HEATING

COIL

FAN

FAN

SWITCH

POWER

3-WAY

MIXING

VALVE

HOT

WATER

SUPPLY

HOT

WATER

RETURN

C3032

DISCHARGE

AIR

THERMOSTAT

RETURN

AIR

FILTER

HEATING OR

COOLING COIL

FAN

POWER

TIME

CLOCK

3-WAY

MIXING

VALVE

SUPPLY

PIPE-MOUNTED

SENSOR

RETURN

HOT

WATER

OR

CHILLED

WATER

Fig. 33. Digitally Controlled Two-Pipe

Heating/Cooling Fan Coil Unit.

M15317

FILTER

FAN

RA

OUTDOOR AIR

ON

CONTROL

PROGRAM

-1.5

24

24

8

13

77

HEATING

DEADBAND

WALL MODULE

TEMPERATURE

COOLING

SETPOINT

PERCENT

OPEN

Loading...

Loading...