ENGINEERING MANUAL OF AUTOMATIC CONTROL

VALVE SELECTION AND SIZING

438

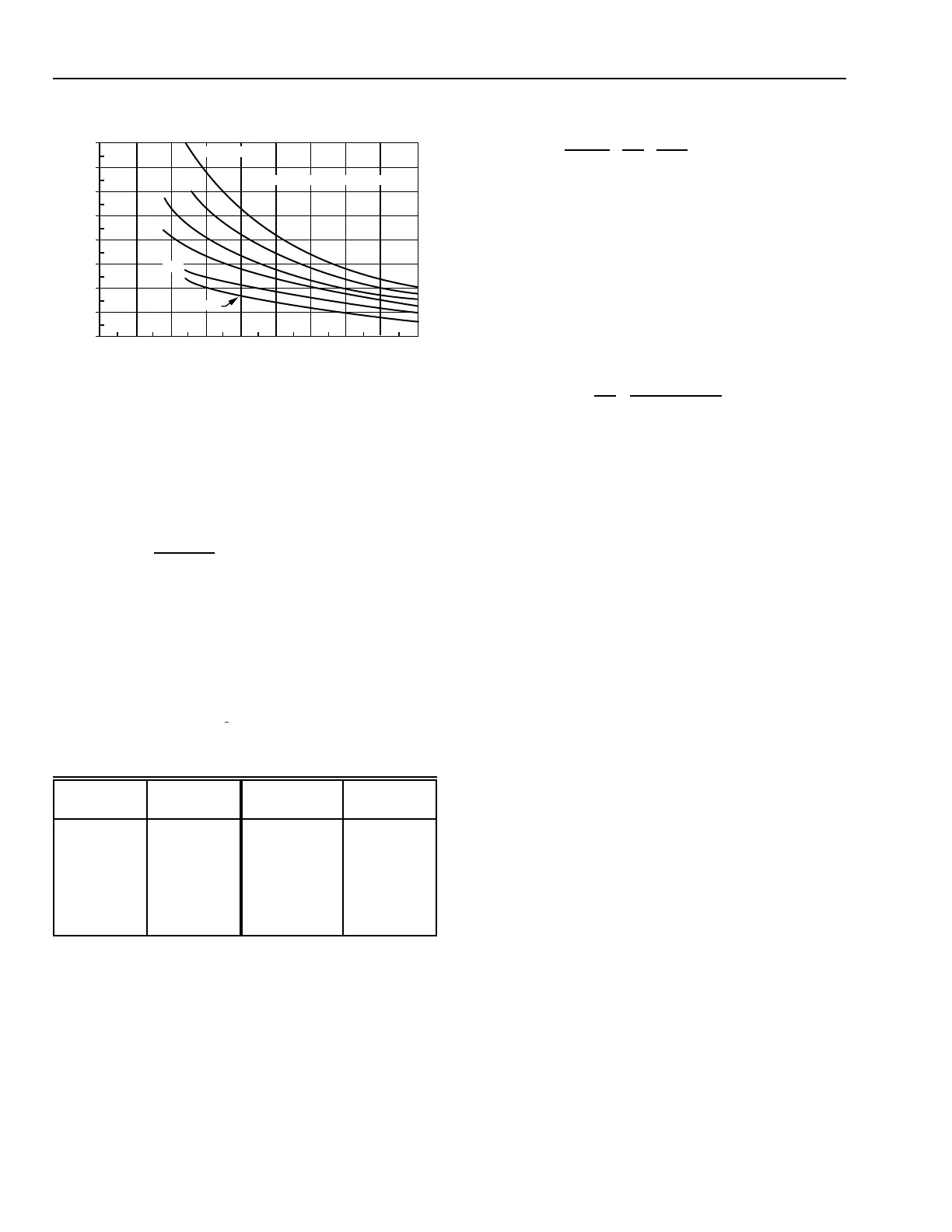

REPRINTED BY PERMISSION FROM ASHRAE HANDBOOK—

1996 HVAC SYSTEMS AND EQUIPMENT

Fig. 15. Pressure Drop Correction for

Propylene Glycol Solutions.

QUANTITY OF WATER

To find the quantity of water (Q) in cubic meters per hour

use one of the following formulas:

1. When heat flow rate is known:

Where:

watts = Heat flow rate.

∆T

w

= Temperature difference of water entering

and leaving the coil.

S = Value from Table 3; based on temperature of

water entering the coil.

Table 3. Water Flow Formula Table.

2. For hot water coil valves:

Where:

m

3

/s = Airflow through the coil.

1202.4 = A scaling constant.

∆Ta = Temperature difference of air entering and

leaving the coil.

S = Value from Table 3; based on temperature of

water entering the coil.

∆T

w

= Temperature difference of water entering

and leaving the coil.

3. For fan system chilled water coil valves:

Q=

watts

S • ∆T

w

Where:

m

3

/s = Airflow through the coil.

Heat removed =Heat per kilogram of dry air removed in kJ/

kg. Includes both sensible and latent heat.

1.02 = A scaling constant.

∆T

w

= Temperature difference of water entering

and leaving the coil.

WATER VALVE PRESSURE DROP

To determine valve pressure drop:

1. For two-way valves consider the following guidelines for

valve pressure drop:

a. Include the pressure drop in the design of the

water circulating system.

— In systems with two-way valves only, it is often

necessary to provide a pump relief bypass or

some other means of differential pressure

control to limit valve pressure drops to the

valve capabilities. For control stability at light

loads, pressure drop across the fully closed

valve should not exceed triple the pressure drop

used for sizing the valve.

— To avoid high pressure drops near the pump,

reverse returns are recommended in large

systems.

-20 -10 0 10 20 30 40 50 60 70

PRESSURE DROP CORRECTION FACTOR

TEMPERATURE, °C

M15320

0.8

0.9

1.1

1.3

1.5

1.0

1.2

1.4

1.6

PROPYLENE GLYCOL SOLUTION

WATER

10%

20%

30%

40%

50% BY MASS

Water

Temp °CS

Water

Temp °CS

20

30

40

50

60

75

90

1158

1154

1150

1145

1141

1134

1128

105

120

135

150

165

180

200

1121

1114

1108

1101

1094

1088

1080

Q = 1.02

m

3

s

•

Heat removed

∆Tw

Loading...

Loading...