ENGINEERING MANUAL OF AUTOMATIC CONTROL

CHILLER, BOILER, AND DISTRIBUTION SYSTEM CONTROL APPLICATIONS

377

C2583

INSTANTANEOUS

CONVERTER

PUMP

OA

DAMPER

ACTUATOR

OA

N.C.

PREHEAT OR

TEMPERING

COIL

LOW TEMP CONTROLLER

TO SHUT DOWN FAN

FAN

TEMPERATURE

CONTROLLER

TEMPERATURE

CONTROLLER

HIGH LIMIT

FOR CONVERTER

(CLOSES VALVE ON

TEMP. RISE)

EXPANSION

TANK

HTWS HTWR

VALVE

RELAY-

CLOSES

VALVE WHEN

FAN STOPS

POWER

FROM

FAN

CIRCUIT

RELAY-CLOSES OA DAMPER

ON FAN SHUTDOWN

A constant temperature hot water supply is used where a

minimum temperature is required for all or part of the converter

load. Normally a converter for space heating does not require

fast response as the load changes only as fast as occupancy and

outdoor air conditions change. Because of the inherent fast

converter response there are several control requirements:

1. The primary sensing element must be located in outlet

water as close to the converter as possible.

2. A stainless steel well that matches the element with heat

conductive compound in the well must be used.

3. A primary control must be used that has integral action

and integral cutout to allow a wider throttling range for

stability with minimum deviation from setpoint and to

eliminate integral windup.

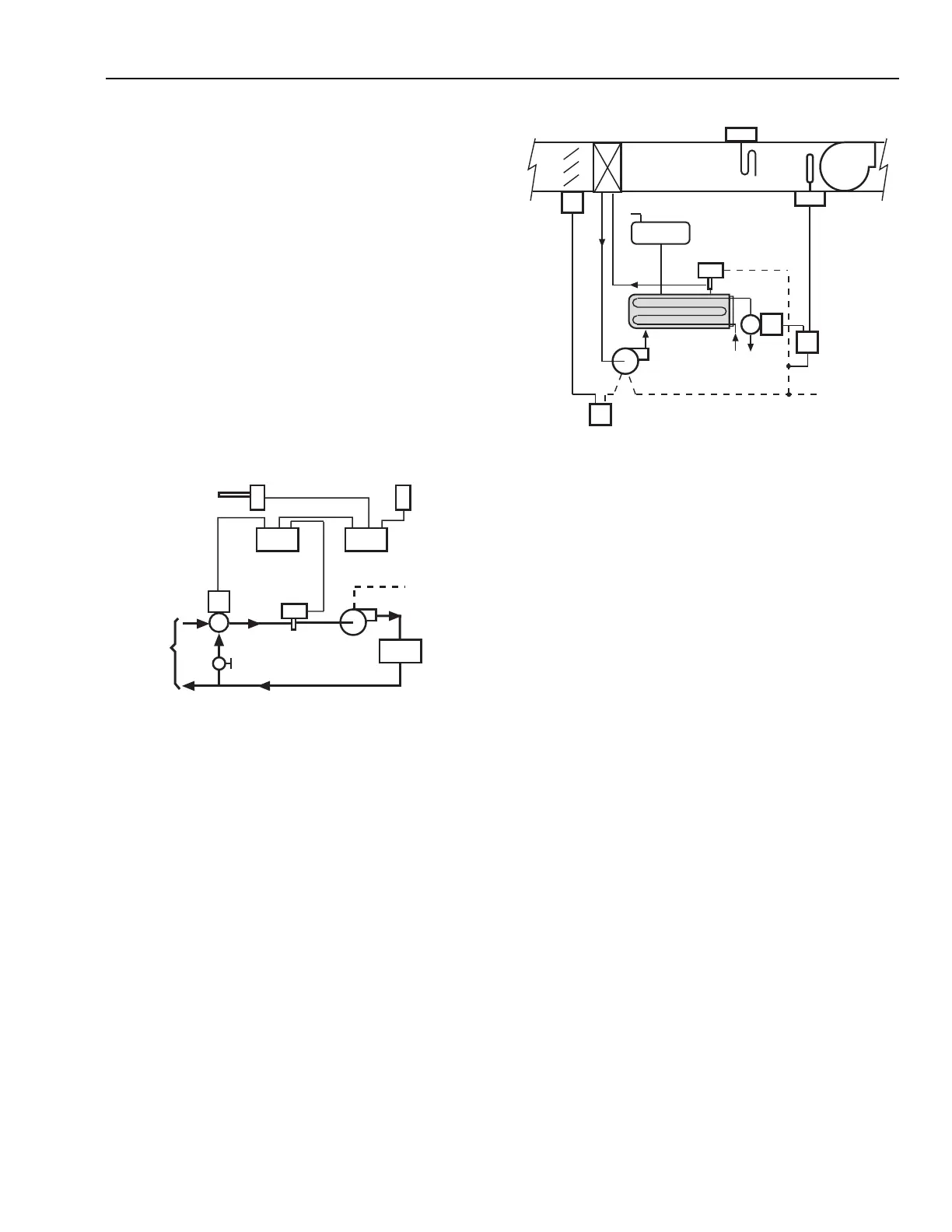

A control arrangement for a typical zone supplied with HW

from a HTW to constant temperature HW converter is shown

in Figure 119. Water temperature in the converter shell must be

reset from the outdoor air temperature for best control. Zones

typically are also reset from outdoor temperature.

Fig. 119. Typical Zone Control of Constant

Temperature HW from HTW Instantaneous Converter.

For modulating control, instantaneous converters must

operate with at least half design flow. To accomplish this, reset

schedules of controller C1 (Fig. 118) and C2 are arranged so

that valve V2 will be between half and full open to the converter

under normal conditions of operation. The reset schedule for

the converter is slightly higher than the temperature normally

required in the zones so that most of the water to supply the

needs of the zones must come from the converter rather than

the bypass.

C2 as the primary control prevents C3 from positioning V2

so the return water bypasses the converter. If flow is cut off

through the converter, the sensor located in the outlet piping

rather than within the shell cannot control V1 in a stable manner.

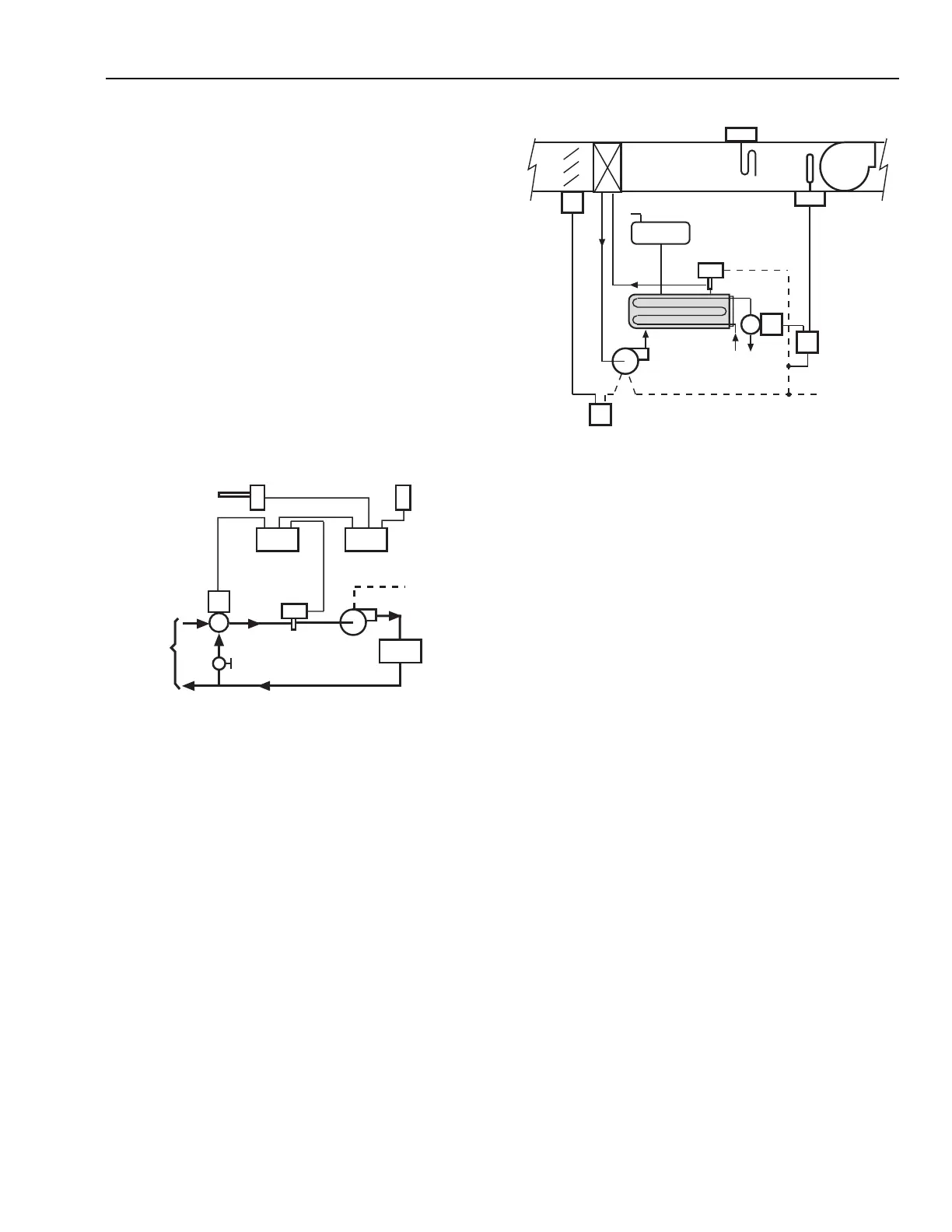

The use of an instantaneous converter (Fig. 120) for heating

water supplied directly to an air heating coil provides fast

response. Control system selection problems are the same as

for the control of a coil supplied with low or medium

temperature water except that a high quality valve with fast

control response is required for HTW.

Fig. 120. Instantaneous Converter Control for HTW

to Glycol Solution for Outdoor Air Preheat.

Where coils are exposed to freezing temperatures, as in a

100 percent outdoor air supply unit, the cost of installing a

foolproof control system plus necessary duct work and dampers

make the use of a water supplied coil questionable. Flow to the

coil should be constant with variable temperature. Better

protection against freezing is obtained by use of a heat transfer

fluid such as a glycol solution.

Glycol solutions used with HTW heating must be closely

monitored. Solutions of ethylene or propylene glycol assume

the corrosivity of the water from which they are prepared and

are oxidized by air into acidic products. The deterioration rate

of inhibitors and stabilizers added to commercial glycol is

influenced by temperature, amount of air in the solution, and,

to some extent, the metals in the piping system. Heat exchanger

surfaces should be kept below 140°C as temperatures above

148°C accelerate deterioration of inhibitors.

If HTW flow is stopped while the air handling unit continues

to operate with below freezing entering air temperature, heat

transfer solution returning to the converter could cause the

converter to freeze. A low-limit duct temperature controller is

recommended to stop the fan if a low air temperature leaving

the coil is sensed.

HTW COILS

Figure 121 shows an acceptable method of mixed air control

when there is a possibility of freezing air passing through the

heating coil. Face and bypass dampers control the heat output

of the coil during normal operation. When the outdoor

temperature rises so that no heat is needed from the coil, valve

V1 closes preventing overheating from the down stream side

of the coil. The low-temperature limit controller senses the air

temperature leaving the coil and opens the valve on sensing a

freezing temperature. Use of a glycol solution as shown in

Figure 120 is recommended.

C2934

OUTDOOR

AIR SENSOR

TO HTW

CONVERTER

ZONE

HIGH-LIMIT

INTERLOCKED

TO CLOSE

HTW VALVE

WHEN

ALL PUMPS OFF

MANUAL

BALANCING VALVE

VALVE V2

CONTROLLER

C2

CONTROLLER

C3

IMMERSION

SENSOR

LOAD

Loading...

Loading...