ENGINEERING MANUAL OF AUTOMATIC CONTROL

VALVE SELECTION AND SIZING

441

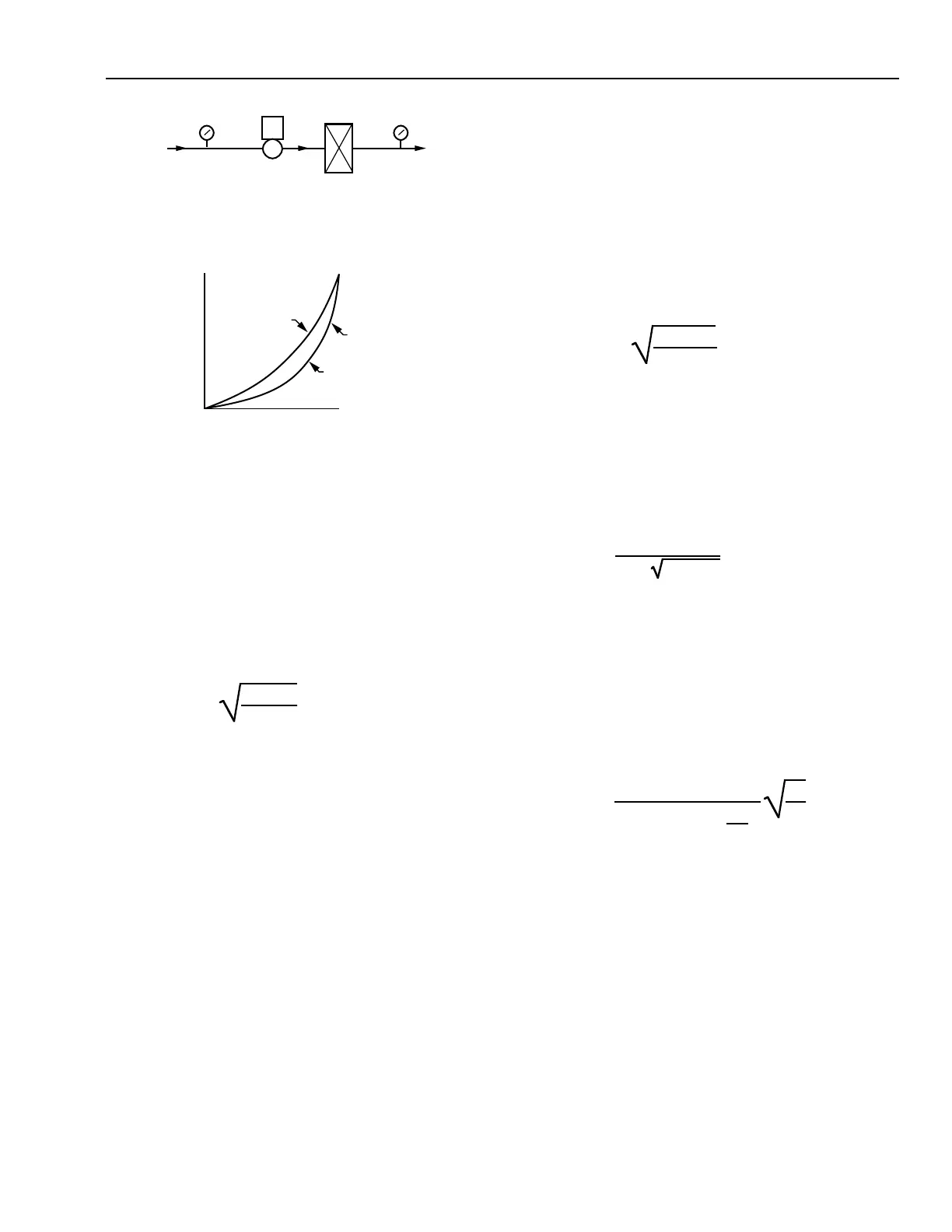

Fig. 17. Equal Percentage Valve Hot Water Application.

Since the valve pressure drop (∆P) should be equal to or

greater than the drop through the heat exchanger and

fittings, 4.82 kPa is used as the valve pressure drop.

For optimum control, a manual balancing valve is

installed in the bypass line to equalize the pressure drops

in the exchanger and bypass circuits.

Substituting the flow of water, density of water, and

pressure drop in the K

v

formula shows that the valve

should have a K

v

of 72.8 or 73.

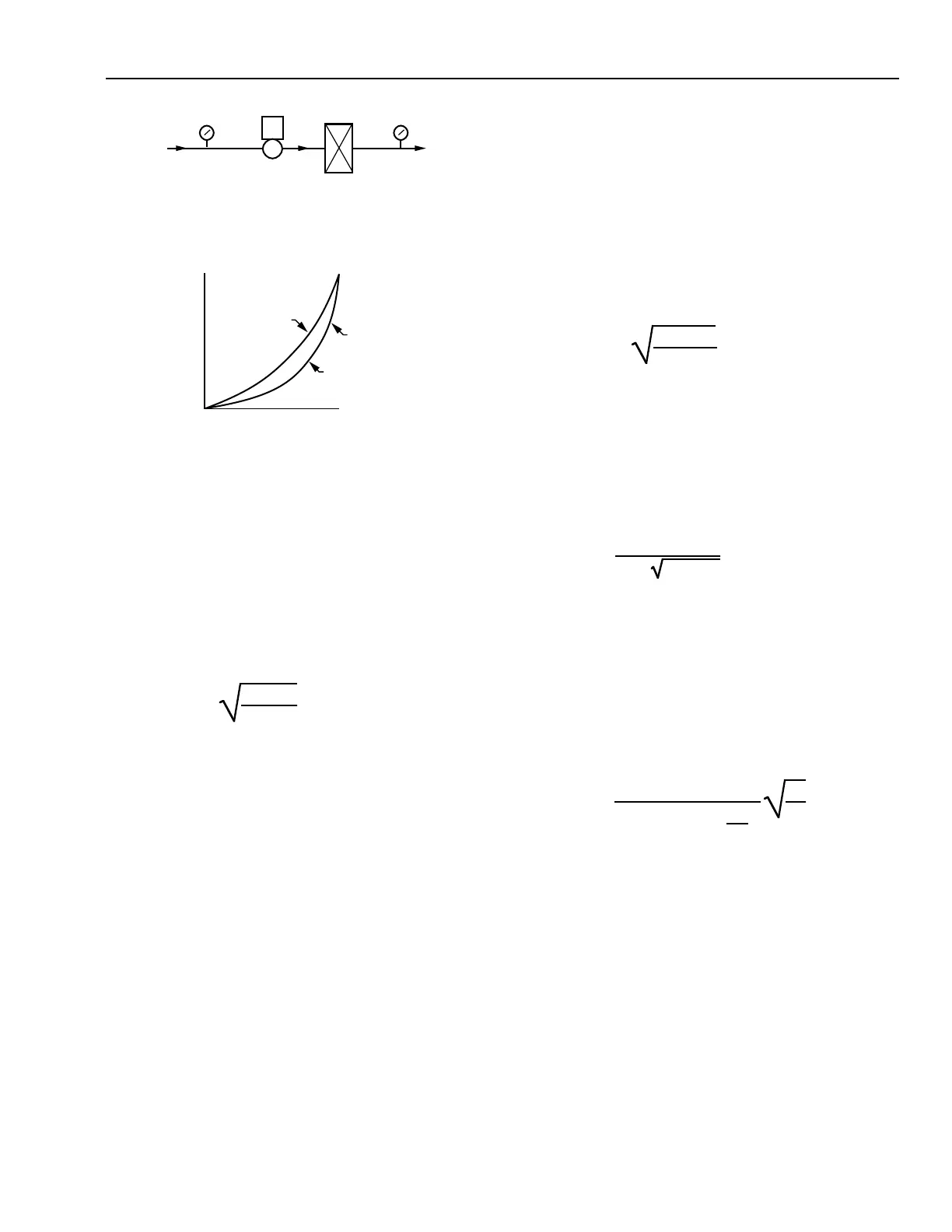

Fig 18. Effect of Pressure Drop

in Hot Water Valve Sizing.

EXAMPLE 4:

A three-way mixing valve is needed for a heat exchanger

application with a bypass line. Water flow is specified at

the rate of 16 m

3

/h. Manufacturer data for the exchanger

indicates a pressure drop of 4.2 kPa through the exchanger

coils.

Use the water valve K

v

formula to determine capacity

index for Valve V1 as follows:

100%

0% 100%

STEM TRAVEL

FLOW AT CONSTANT

PRESSURE DROP

C2340

70%

PRESSURE

DROP

30%

PRESSURE

DROP

IDEAL EQUAL

PERCENTAGE

VALVE

CHARACTERISTIC

Where:

Q = Flow of fluid required to pass through the

valve is 16 m

3

/h.

ρ = Density of water is 1000.

∆P = Pressure drop across the valve. Plans of the

heating system indicate 80-mm supply and

return mains. From an elbow equivalent

table and pipe friction chart found in the

ASHRAE Handbook or other reference

manuals, the calculated pressure drop

through a 80-mm tee and the piping from the

valve and the tee to the exchanger is

0.62 kPa. Heat exchanger pressure drop is

4.2 kPa. Total pressure drop from bypass

connection through the heat exchanger and

to the hot-water input of the three-way valve

is 4.2 kPa + 0.62 kPa or 4.82 kPa.

Select a linear valve providing close control with a

capacity index of 73

STEAM VALVES

Calculate the required capacity index (K

v

) for a valve used

in a saturated steam application, using the formula:

Where:

Q = Quantity of steam in kilograms per hour

required to pass through the valve.

0.224 = A scaling constant.

∆P = Pressure drop in kPa.

P

o

= Absolute outlet pressure of valve in

kilopascals (P

1

– ∆P).

Calculate the required capacity index (K

v

) for a valve used

in a superheated steam application, using the formula:

Where:

Q = Quantity of steam in kilograms per hour

required to pass through the valve.

∆P = Pressure drop in kPa.

P

1

= Absolute inlet in kilopascals.

V

1

= Inlet specific volume in cubic centimeters

per kilogram.

Determining the K

v

for a steam valve requires knowing, the

quantity of steam (Q) through the valve, the pressure drop (∆P)

across the valve, and the degrees of superheat. See QUANTITY

OF STEAM and STEAM VALVE PRESSURE DROP. Then

select the appropriate valve based on K

v

, temperature range,

action, body ratings, etc., per VALVE SELECTION guidelines.

K

v

=Q

ρ

∆P • 10

K

v

=16

1000

4.82 • 10

= 72.8

K

v

=

Q

0.224

∆P • P

o

K

v

=

Q

3.15 –

()

1.55 •

∆P

P

1

V

1

∆P

VALVE VI

C4369

80°C

HOT WATER

SUPPLY

275 kPa

HOT WATER

RETURN

HEATING

COIL

LOCAL

PIPING

15 kPa

DROP

4.54 m /h AT DESIGN,

30 kPa DROP

30% PRESSURE DROP, Kv = 10

70% PRESSURE DROP, Kv = 4.4

CASE B: 425 kPa

CASE A: 345 kPa

3

Loading...

Loading...