ENGINEERING MANUAL OF AUTOMATIC CONTROL

BUILDING AIRFLOW SYSTEM CONTROL APPLICATIONS

289

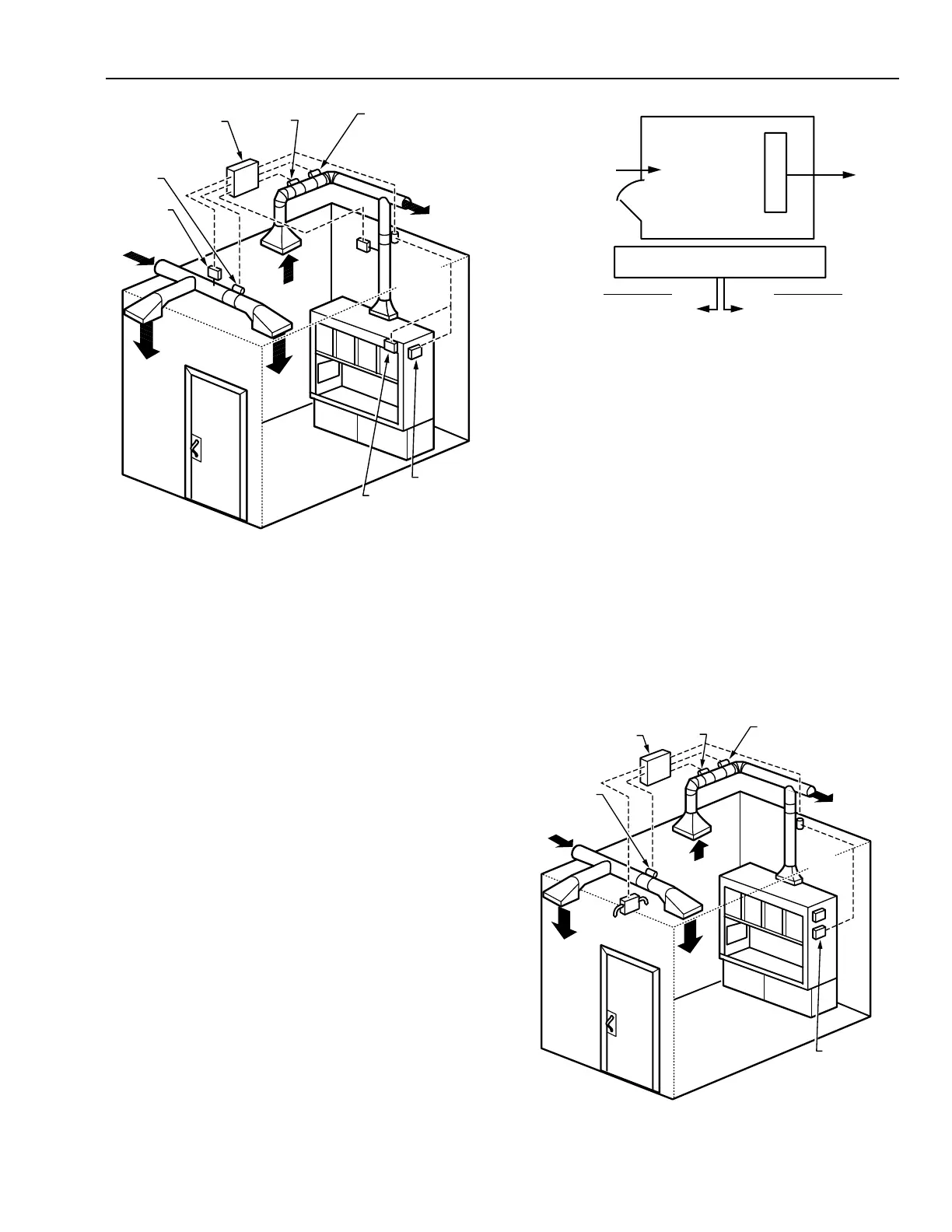

M12216

SUPPLY

AIR

SUPPLY

AIR TO

LAB

GENERAL

EXHAUST

AIR

EXHAUST

AIR

FUME

HOOD

DAMPER

ACTUATOR

SUPPLY

AIR TO

CORRIDOR

DIFFERENTIAL

PRESSURE

SENSOR

VELOCITY

SENSOR

SUPPLY AIR

DAMPER

ACTUATOR

EXHAUST AIR

DAMPER ACTUATOR

AIRFLOW

SENSOR

LAB AIRFLOW

CONTROLLER PANEL

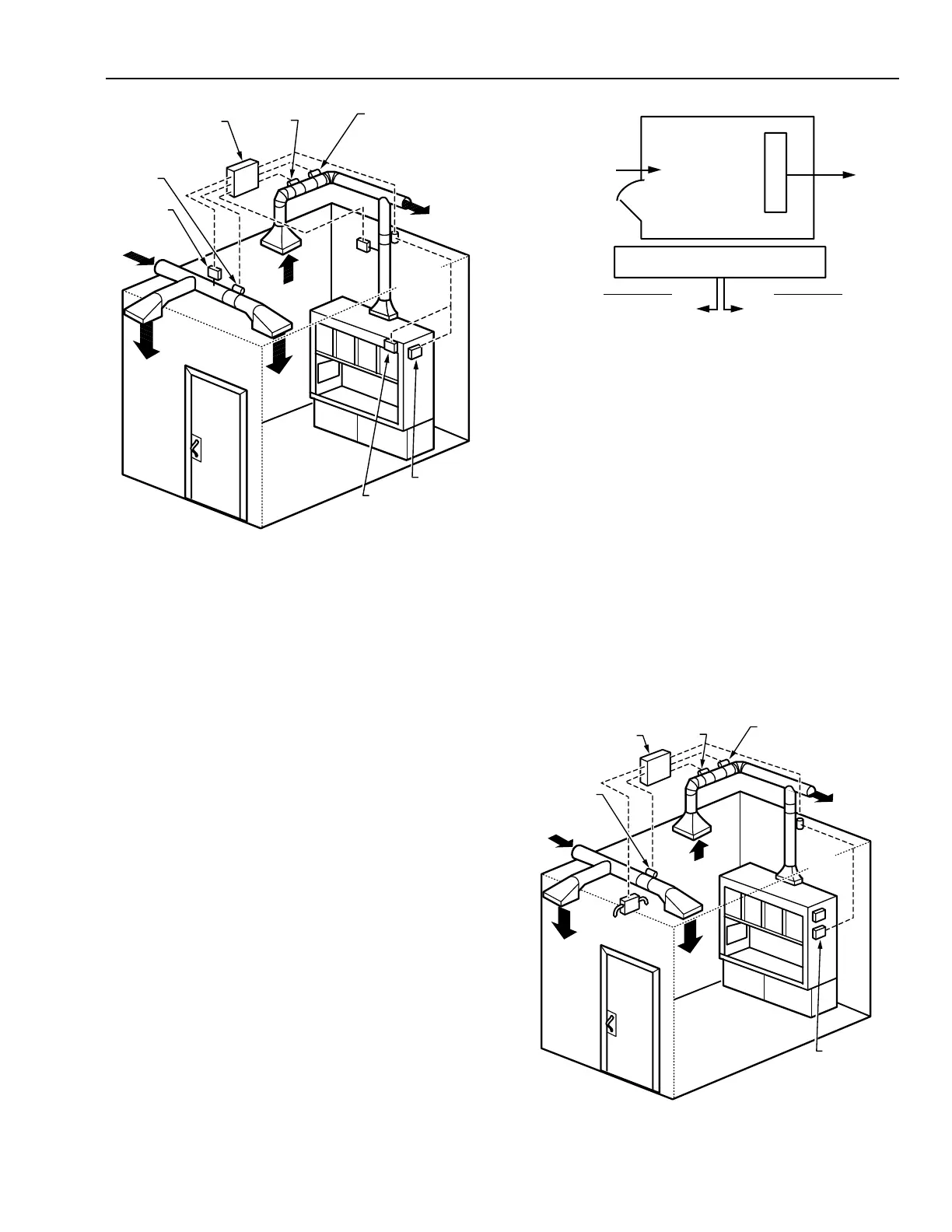

M12215

SUPPLY

AIR

SUPPLY

AIR TO

LAB

GENERAL

EXHAUST

AIR

EXHAUST

AIR

DAMPER

ACTUATOR

OR

AIR VALVE

AIRFLOW

SENSOR

SUPPLY

AIR TO

CORRIDOR

VELOCITY

SENSOR

DAMPER

ACTUATOR

OR AIR

VALVE

AIRFLOW

SENSOR

DAMPER ACTUATOR

OR AIR VALVE

AIRFLOW

SENSOR

LAB AIRFLOW

CONTROLLER PANEL

OR

SASH

SENSOR

Fig. 46. Airflow Tracking Control.

Airflow sensors located in all supply and exhaust ducts

provide flow signals which can be compared by a controller.

Sensor locations must meet the manufacturers minimum

installation guidelines, such as velocity range and length of

straight duct before and after the sensor, to ensure accuracy.

Materials and finishes for sensors in exhaust ducts exposed to

corrosive fumes must be carefully selected.

If future flexibility and changing lab configurations are

important considerations, then flow sensor location, duct size,

supply airflow rate, and control system design should all include

capabilitiy to be modified in the future.

A characteristic of airflow tracking is stability of the system in

the face of breaches to the lab envelope. This is most often lab

door openings. In a laboratory maintained at a negative pressure,

the space static pressure increases and the air velocity through all

openings drops significantly when a door opens. Figure 47 shows

a laboratory example with a single fume hood, a single door 1m

wide x 2m high (2m

2

), and a crack area estimated at 0.05 m

2

. If

the fixed airflow tracking differential is 0.1 m

3

/s, the average

velocity through the cracks would be 2.0 m/s which is more than

adequate for containment. However, when the door opens, the

average velocity in this example decreases to 0.05 m/s which is

marginal to inadequate for containment.

However, the ability of the tracking system to quickly

(usually within several seconds) react and compensate for door

openings and other breaches is a positive characteristic of this

control method.

Fig. 47. Airflow Tracking Example with

Door Closed and Opened.

Supply duct pressure and building pressurization control are

simpler and more stable with airflow tracking because they are

less affected by this type of unexpected upset. The supply duct

pressure control remains stable due to fewer disruptions. Building

pressurization, defined as the difference between total air leaving

the building and the total air entering, remains the same.

Direct pressure control (Fig. 48) provides the same control

function as airflow tracking but its characteristics are quite

different. Direct space pressurization control senses the

differential pressure between the space being controlled and a

reference space which is usually an adjacent space or hallway.

Figure 49 shows a similar example of negative space

pressurization utilizing direct pressure control. If the airflow

through the hood is 0.5 m

3

/s and the pressure control reduces

the supply airflow when the door is opened, the average velocity

through openings drops from 2.0 m/s to 0.25 m/s.

Fig. 48. Direct Pressure Control.

CRACK AREA = 0.05 m

2

SUPPLY

DOOR

0.4 m

3

/s

0.5 m

3

/s

0.7 m

3

/s

2 m

2

FUME HOOD

EXHAUST

DOOR CLOSED

= 2 m/s

DOOR OPENED

= 0.05 m/s

DIFFERENTIAL = EXHAUST – SUPPLY

= 200 CFM

C4076

VELOCITY = 0.1 2.05

÷

VELOCITY = 0.1

0.05

÷

Loading...

Loading...