Intermec EasyCoder 501 E – Installation & Operation Ed. 1 109

Chapter 11

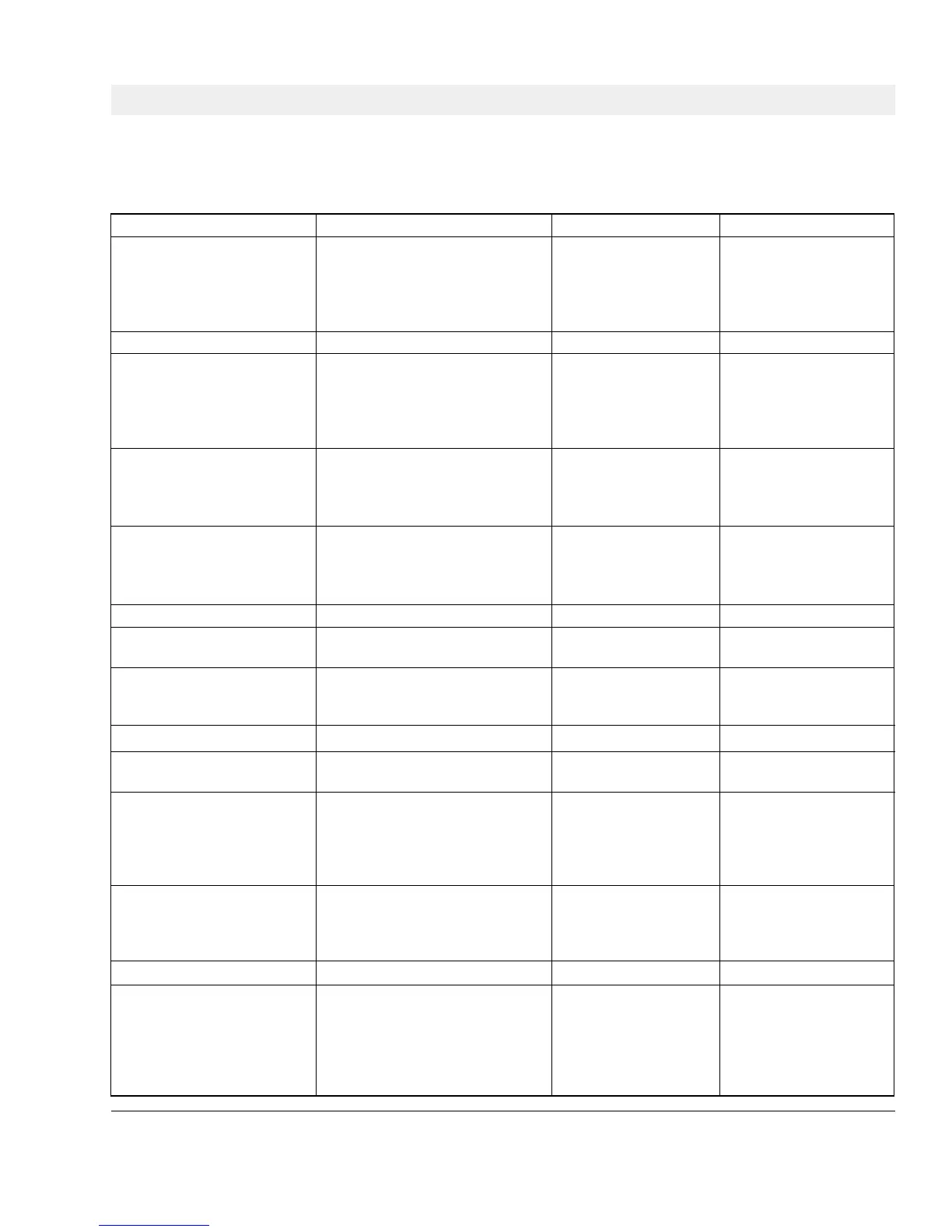

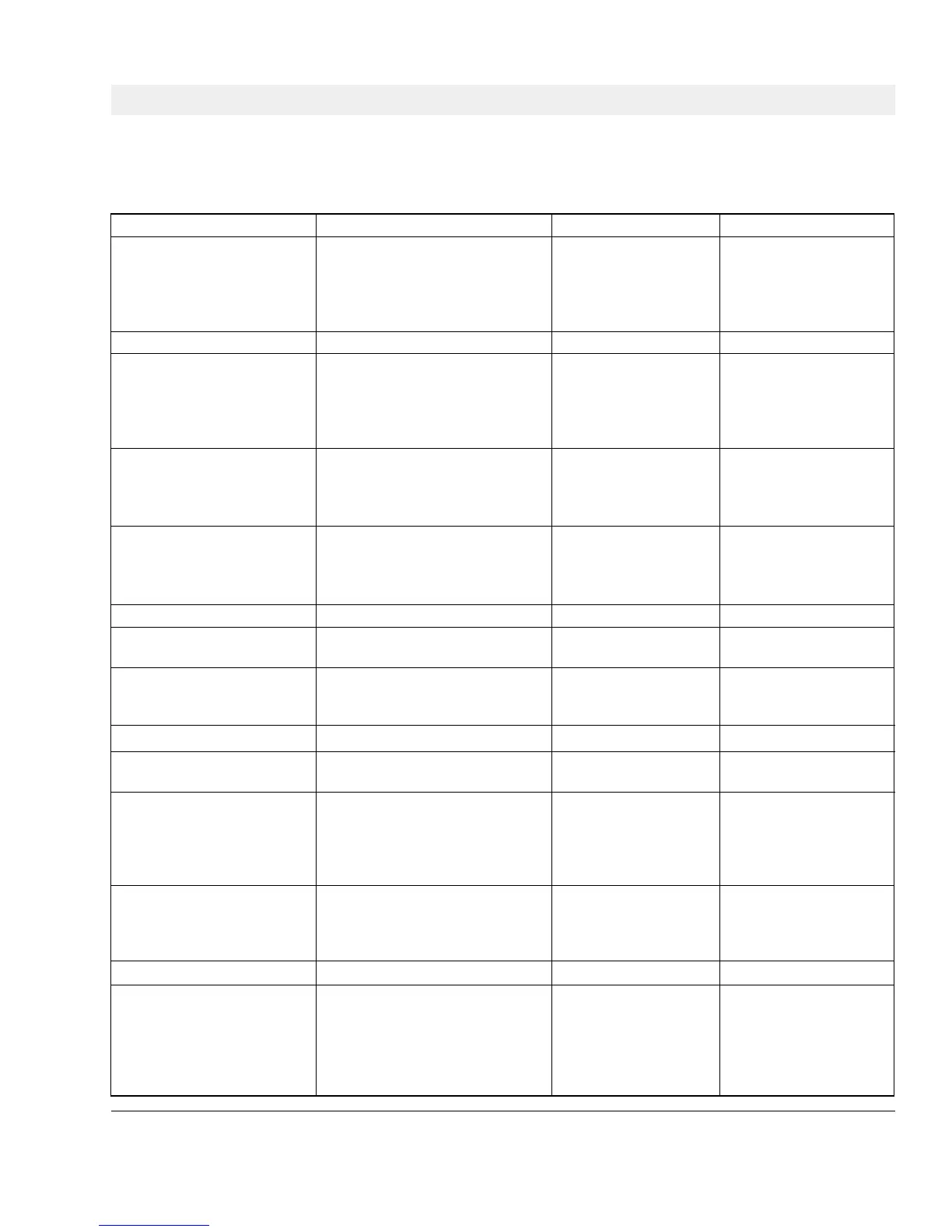

Symptom Possible Cause Remedy Refer to

Overall weak printout Wrong Paper Type parameter Change parameter Chapter 7

Contrast value too low Change parameter Chapter 7

Printhead pressure too low Adjust both knobs Chapter 13

Worn printhead Replace printhead Chapter 12

Wrong printhead voltage Replace CPU board ☎ Call Service

Printout weaker on one side Uneven printhead pressure Adjust outer knob Chapter 13

Weak spots Foreign particles on media or ribbon Clean or replace Chapters 5 & 6

Media/ribbon don’t match Change to matching media Chapter 7

Poor media or ribbon quality Use Intermec media/ribbon Appendix 2

Worn printhead Replace printhead Chapter 12

Worn platen roller Check/replace ☎ Call Service

Overall dark printout Wrong Paper Type parameter Change parameter Chapter 7

Contrast value too high Change parameter Chapter 7

Printhead pressure too high Adjust Chapter 13

Wrong printhead voltage Replace CPU board ☎ Call Service

Excessive bleeding Wrong Paper Type Change parameter Chapter 7

Contrast value too high Change parameter Chapter 7

Printhead pressure too high Adjust both knobs Chapter 13

Faulty energy control Replace CPU board ☎ Call Service

Dark lines along media path Foreign objects on printhead Clean printhead Chapter 12

White lines along media path Printhead dirty Clean printhead Chapter 12

Missing dots on printhead Replace printhead Chapter 12

Large part of dot line missing Wrong X-start or Width parameter Change parameter Chapter 7

Failing printhead Replace printhead Chapter 12

Failing strobe signal Check CPU-board ☎ Call Service

Last part of print image missing Too small image buffer Increase buffer size Chapter 7

Printout missing along inner edge Bad media alignment Adjust Chapter 5

X-start parameter value too low Increase Chapter 7

Transfer ribbon breaks Ribbon not fi tted correctly Reload ribbon Chapter 6

Wrong paper type parameter (too much Change parameter, Chapter 7

energy) then clean printhead Chapter 13

Ribbon supply hub stuck Adjust ☎ Call Service

Bad energy control Adjust ☎ Call Service

Transfer ribbon wrinkles Ribbon supply hub not centered Adjust Chapter 13

Ribbon obstructed by printhead cable Clear n.a.

Incorrect edge guide adjustment Adjust Chapter 5

Too strong printhead pressure Adjust Chapter 13

No thermal transfer printout Ink-coated side does not face media Reload ribbon Chapter 6

Media feed not working properly Changed media characteristics Perform a TESTFEED Chapter 5

Wrong start- and stop adjust values Check/change Chapter 7

Wrong Media Type parameter Check/change Chapter 7

Wrong sensor position Check/change Chapter 13

Dirty or blocked LSS Clean Chapter 12

Faulty sensors Replace ☎ Call Service

Troubleshooting

Loading...

Loading...