Intermec EasyCoder 501 E – Installation & Operation Ed. 1 115

Chapter 12 Maintenance

Cleaning the

Ribbon Save

Device (option)

In the optional ribbon save print device, the label stop/black mark

sensor (LSS) is partially enclosed by two black plastic guide plates.

These have been added to prevent thin receiving media from getting

jammed when pushed forward by the rear drive roller at the time

when the printhead is lifted.

The guide plates can easily be removed for cleaning. First, pull the

upper guide straight out. Then, press the snap-lock of the lower

guide by means of a coin or screwdriver and lift the outer end free

before carefully pulling the guide plate out.

Both guide plates are provided with seemingly opaque, smooth

windows, which actually are transparent to the light of the LSS.

These windows must be kept clean from dust, stuck labels and

adhesive residue. Only use isopropyl alcohol for cleaning.

When putting back the guide plates, start with the lower one and

insert the two studs on the inner side into the corresponding holes in

the inner gable. Then press down the outer end so the snap-lock fi ts

into the slot in the outer gable.

The upper guide is threaded onto the beam of the LSS and connects

to the lower guide by means of a pin and a metallic snap-lock.

Do not use excessive force when removing or fi tting the guide

plates!

When needed, the rear rollers can be cleaned using a blotting paper

or soft cloth slightly moistened with isopropyl alcohol.

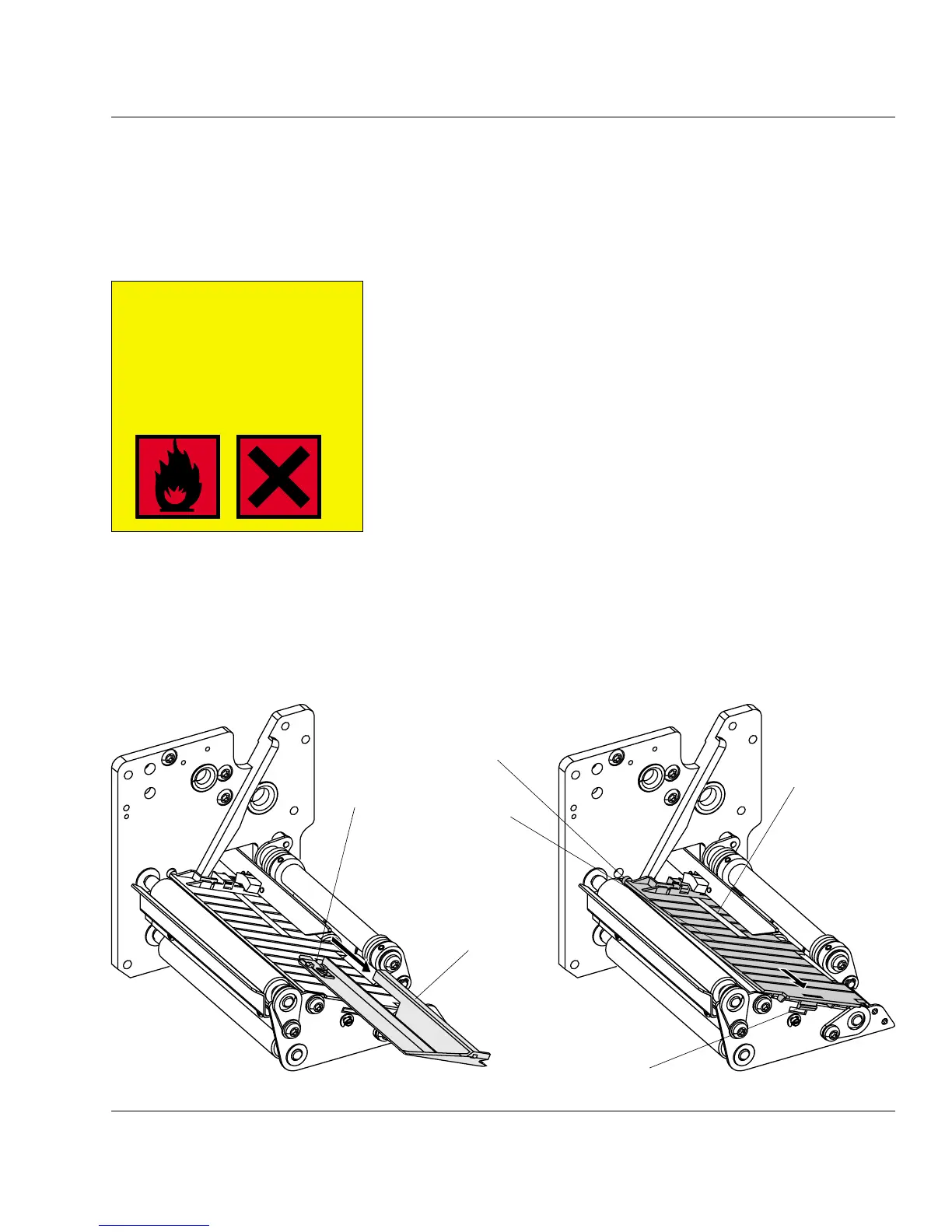

Warning!

Isopropyl alcohol

[(CH

3

)

2

CHOH; CAS 67-63-0]

is a highly fl ammable, moder-

ately toxic, and mildly irritating

substance.

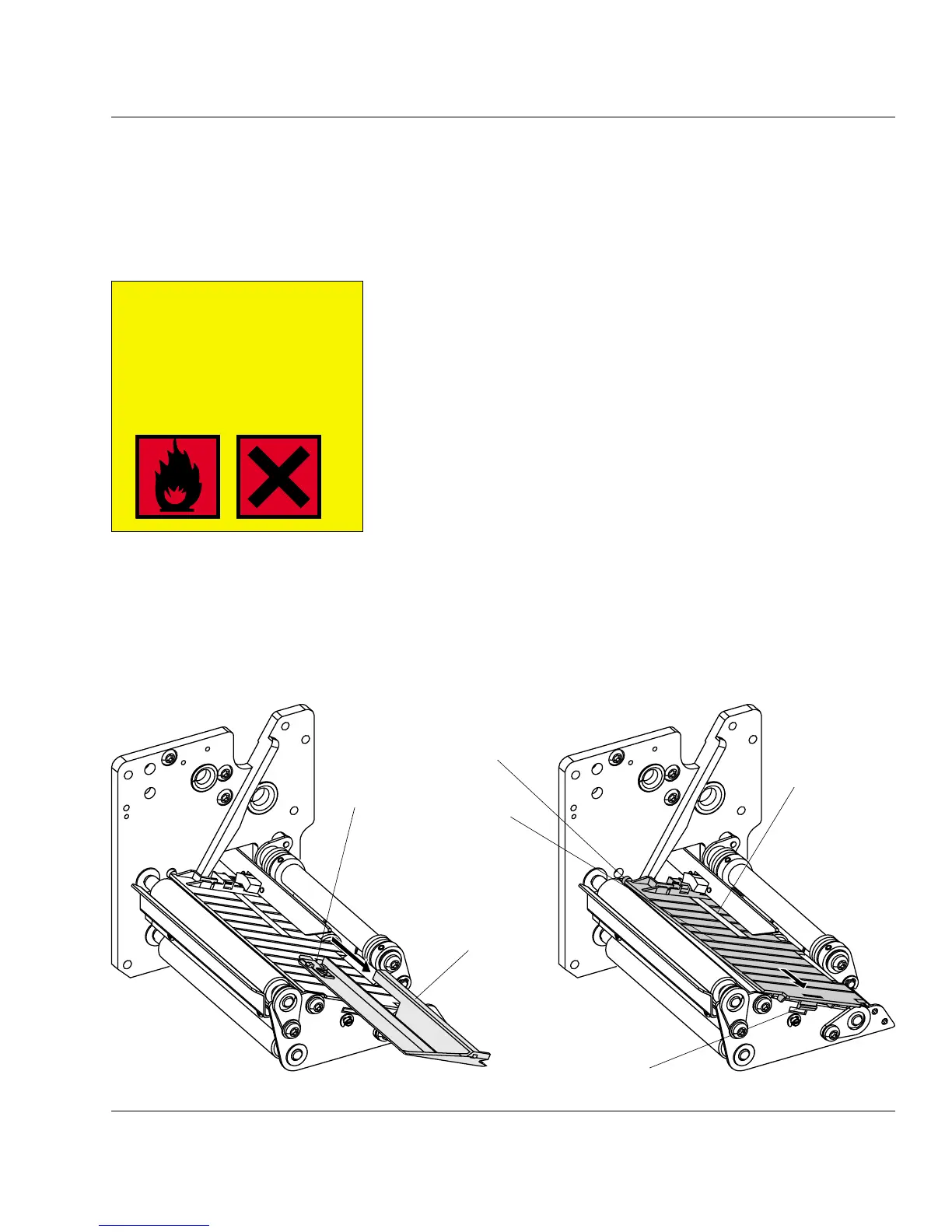

Snap-Lock

Stud

Snap-Lock

Lower Guide

Upper Guide

LSS Window

The upper part of the print unit has been omitted to improve the view of the guides!

Loading...

Loading...