Safety 2

Inthecaseoftip-over

CAUTION

For ease of operation, various functions on your

truck are gas-spring assisted. Gas springs are

complex components which contain high internal

pressures (up to 300 bar).

They may under no circumstance be opened unless

so directed, and may be removed only when not

under compression. Any damage, lateral forces,

buckling, temperatures in excess of 80°C and

heavy soiling must generally be avoided. Damaged

or defective gas springs must be changed immedi-

ately. Please contact your authorised dealer. He

will, if necessary, depressurise the gas spring in

accordance with regulations before dismantling it.

Gas springs must be depressurised before recyc-

ling.

WARNING

The following issues must be observed when an

accumulator is fitted. Improper handling of the

accumulator can lead to serious injuries.

Before working on the accumulator, it must be

depressurised. Please contact your authorised

dealer.

WARNING

Depending on the duration of

operation and use, components

carrying exhaust gases and exhaust

air can become hot.

Therefore wear protective clothing.

WARNING

The forklift truck working area must be adequately

lit.

If it is insufficiently lit, work lights must be installed

to ensure that the driver can see properly

CAUTION

Various items of special equipment fitted to your

truck have the "speed reduction" special function

. It is purely an assistance function. This means

that the driver must not rely solely on the "speed

reduction" function during operation.

The driver is always responsible for safe operation.

CAUTION

The functioning of medical equipment, e.g. pace

makers or hearing aids, may be impaired when

driving.

Check with a doctor or the medical equipment

manufacturer whether the equipment is sufficiently

protected against electromagnetic interference.

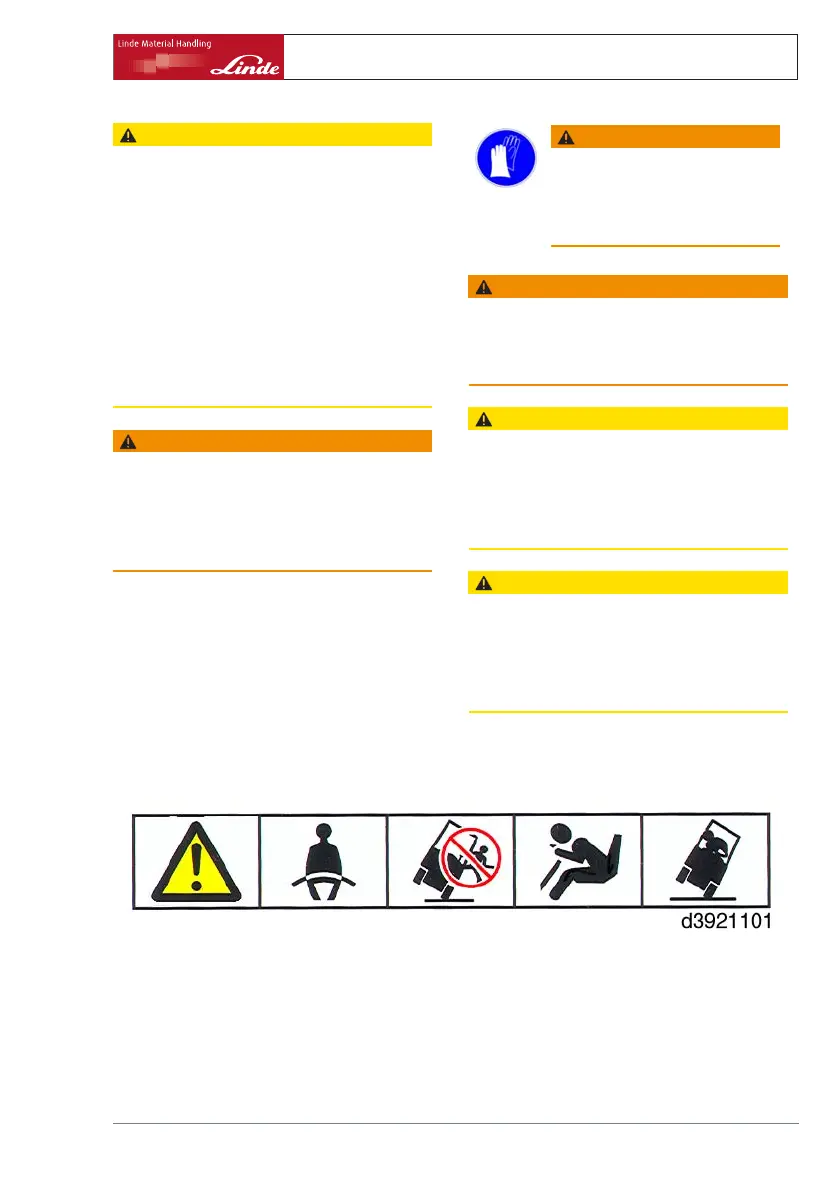

In the case of tip-over

• Stay buckled up

• Don’t jump

• Hold on tight

• Brace feet

•Leanaway

The stability of your truck is ensured if used

properly and as intended. Should the truck

tip over during an unapproved application or

due to incorrect operation, always follow the

instructions depicted below.

Operating Instructions – 393 807 1001 EN – 08/2008 9

Loading...

Loading...