Maintenance 5

Troubleshooting

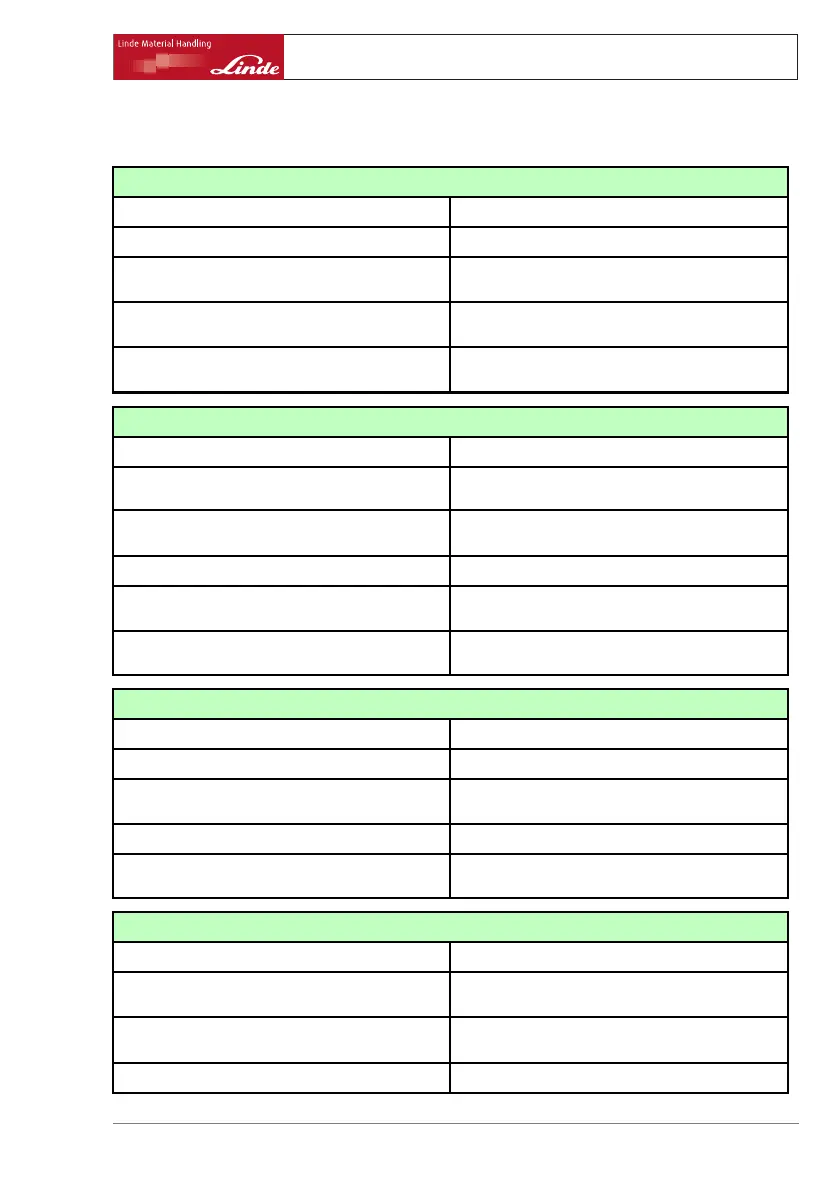

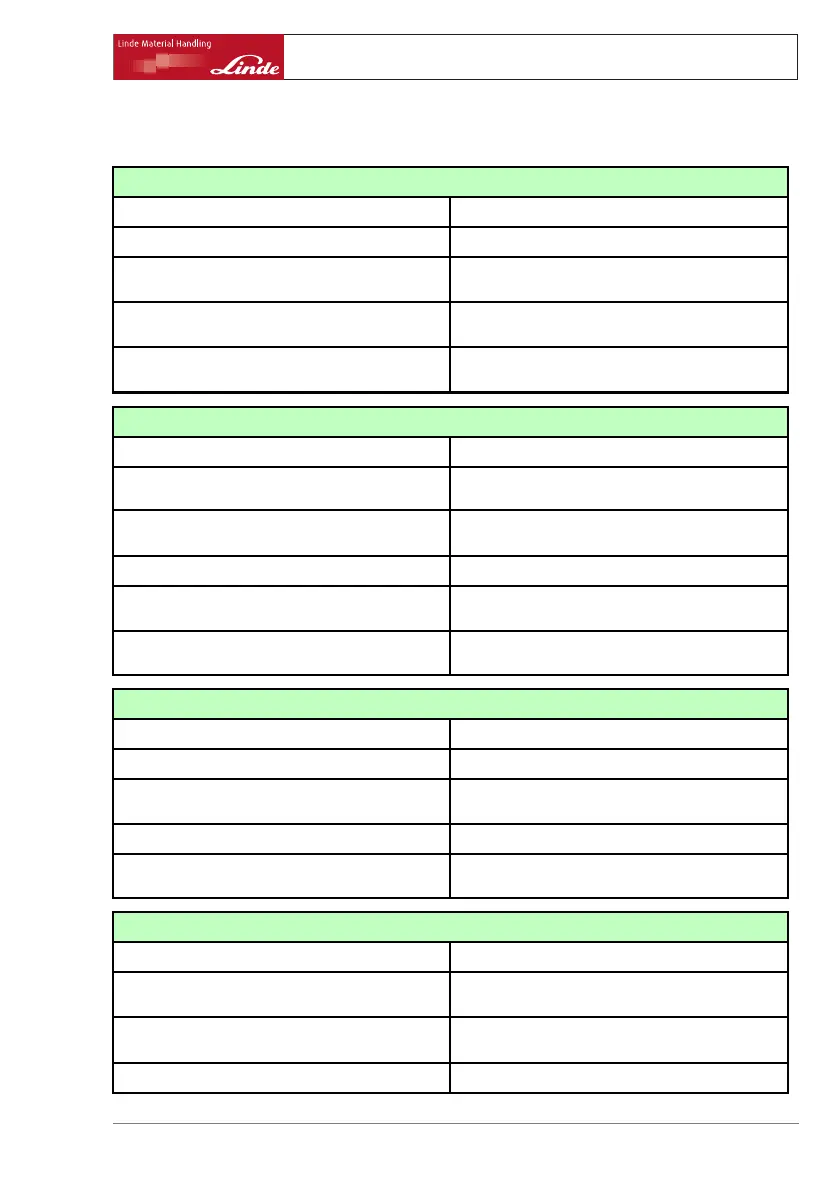

Malfunctions, causes, remedies (hydraulic equipment)

Abnormal noises.

Possible cause

Correction

Clogged suction filter.

Replace the filter.

Leaks in the suction pipe line, oil foaming.

Seal the pipe line. Check the hydraulic oil level,

top up as necessary.

Hydraulic pump or motor damage, defective

seals, causing air to be drawn in.

Have the hydraulic power unit checked by your

authorised dealer.

Incorrect oil viscosity, insufficient oil in the tank

or hydraulic pump.

Change the hydraulic oil; ensure the oil has the

specified viscosity. Top up hydraulic oil.

No pressure or insufficient pressure in the system.

Possible cause

Correction

Suction line damaged, noisy.

Change the hydraulic oil, top up the hydraulic

oil.

Defective pump, loss of pressure, pressure

valves fail to close, valve seat damaged.

Contact your authorised dealer.

Pipe line broken or leaking. Replace pipe line or seal it.

Oil too thin, causing excessive leakage losses.

Change the hydraulic oil; ensure the oil has the

specified viscosity.

Oil temperature indicator lights up.

Check hydraulic oil level, clean hydraulic oil

cooler.

Oil pressure fluctuations.

Possible cause

Correction

Causes as for abnormal noises. See under abnormal noises.

Pressure relief valve or feed pressure valves

jamming.

Please contact your authorised dealer.

Lift and tilt cylinders exhibit chafe points.

Please contact your authorised dealer.

Lift mast does not extend fully, or leans back

somewhat.

Top up hydraulic oil. Bleed the cylinders.

No flow or insufficient flow.

Possible cause

Correction

Clogged filters (if noises also occur at the same

time).

Clean the filter or replace it.

Defective pump, loss of pressure, pressure

valves fail to close, valve seat damaged.

Contact your authorised dealer.

Pipe line broken or leaking.

Replace pipe line or seal it.

Operating Instructions – 393 807 1001 EN – 08/2008 201

Loading...

Loading...