Maintenance 5

Load lift system

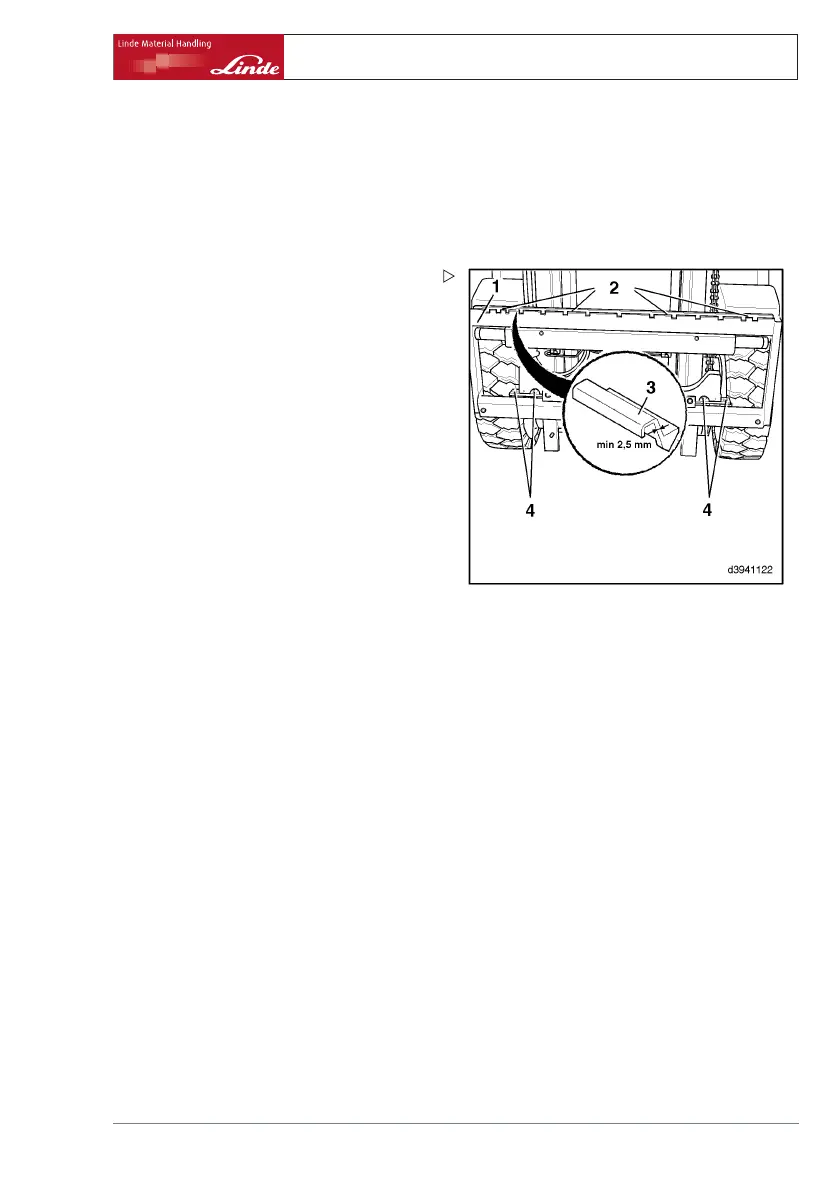

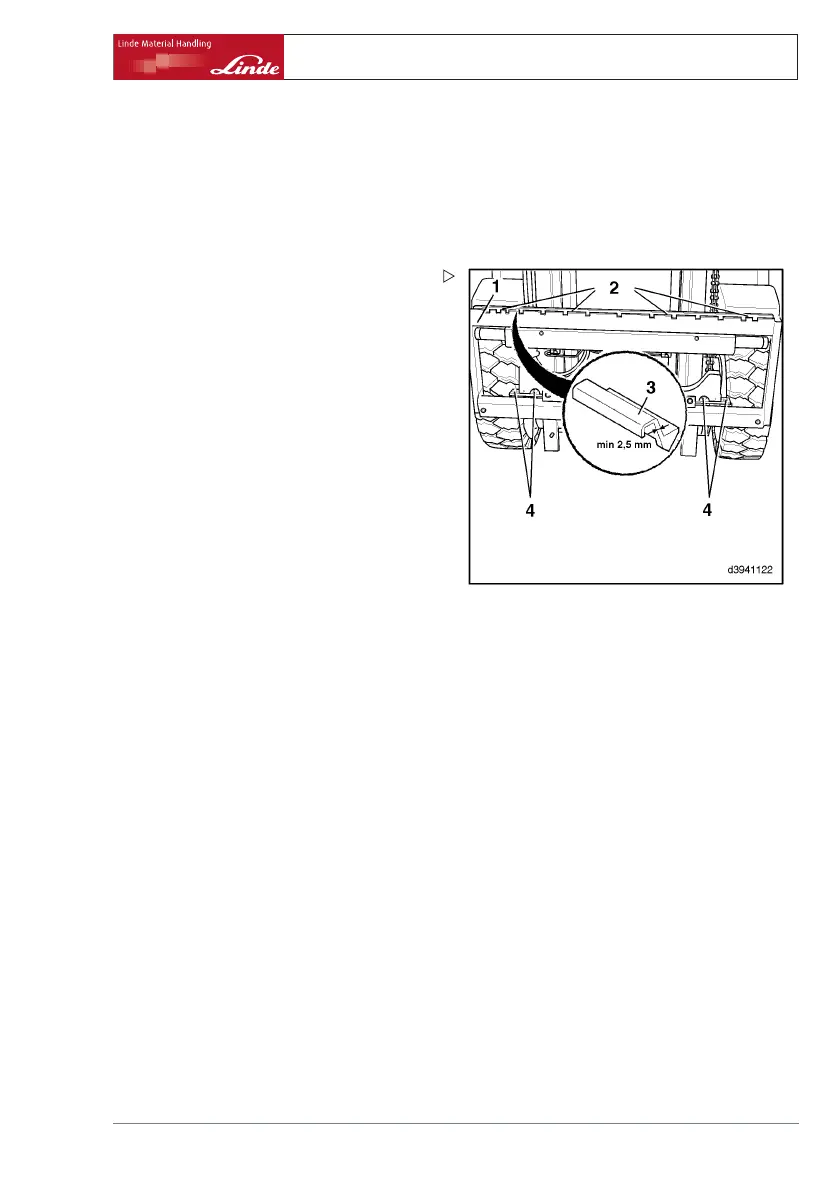

Checking the slide guides on the

sideshift (special equipment) for

wear

¾ Dismantle sideshift.

¾ Clean sideshift.

¾ Remove the slide guides from t

he upper

guide (1).

¾ Measure the wall thickness of the slide

guide (3).

If wall thickness is less than 2.5 mm, change

the slide guides.

¾ Lubricate slide guides.

¾ Reassemble sideshift.

¾ Tilt lift mast forwards and lower fork arms

until they touch the ground, so that sideshift

frame is relieved of the weight of forks.

¾ Lubricate the sideshift at lubri

cating nipples

(2) and (4).

Cleaning and lubricating the fork po-

sitioner (special equipment), check-

ing the fastening

¾ Clean the fork positioner using a steam-jet

cleaner.

¾ Check condition of

fork positioner device

and look for leaks.

¾ Check hydraulic lines for chafing and re-

place if necessary.

¾ Check hydraulic connections for tightness,

replace if necessary.

¾ Check cylinders for

leaks.

¾ Check piston rods for damage.

Operating Instructions – 393 807 1001 EN – 08/2008 181

Loading...

Loading...