8-25

TMS800E SERVICE MANUAL UNDERCARRIAGE

Published 01-29-2014, Control # 496-00

14. Use the correct bushing driver tool to remove the anchor

pin bushings from the spider.

15. Remove the slack adjuster. Reference Slack Adjuster

Removal this Section.

16. Remove the camshaft by grasping the camshaft head

and pulling outboard.

17. Remove the bolts attaching the air chamber bracket to

the spider and pull it away from the spider.

18. Remove spider-to-axle attaching nuts and bolts and

remove the spider.

19. Remove screws and retaining clip securing dust shield

to spider and remove dust shield.

Clean brake parts as outlined below:

1. Wire brush all parts exposed to mud, road dirt, and salt,

to include the spider, air chamber bracket, dust shield,

and exterior of drum.

2. Following the recommendations at the beginning of this

section, use a vacuum cleaner to remove brake dust

from drums. Wipe interior of drums with a greaseless

solvent to remove any spilled oil.

3. Clean all other brake parts thoroughly with a suitable

shop solvent. Wipe dry with a clean, lint-free cloth.

Inspection

1. Check drum for cracks, glazing, grooving, run-out and

out-of-round. Cracked drums must be replaced. Drums

which are glazed, grooved, out-of-round, etc., may be

returned to service if they can be reworked without

exceeding the manufacture’s specifications.

2. Check the spider for expanded anchor pin holes and for

cracks. Replace damaged spiders and anchor pin

bushings.

3. Check the camshaft bracket for broken welds, cracks

and correct alignment. Replace damaged brackets.

4. Check the anchor pins for corrosion and wear. Replace

worn or damaged anchor pins.

5. Inspect the shoes for rust, expanded rivet holes, broken

welds and correct alignment. Replace a shoe with any of

the conditions listed in steps 2 through 5.

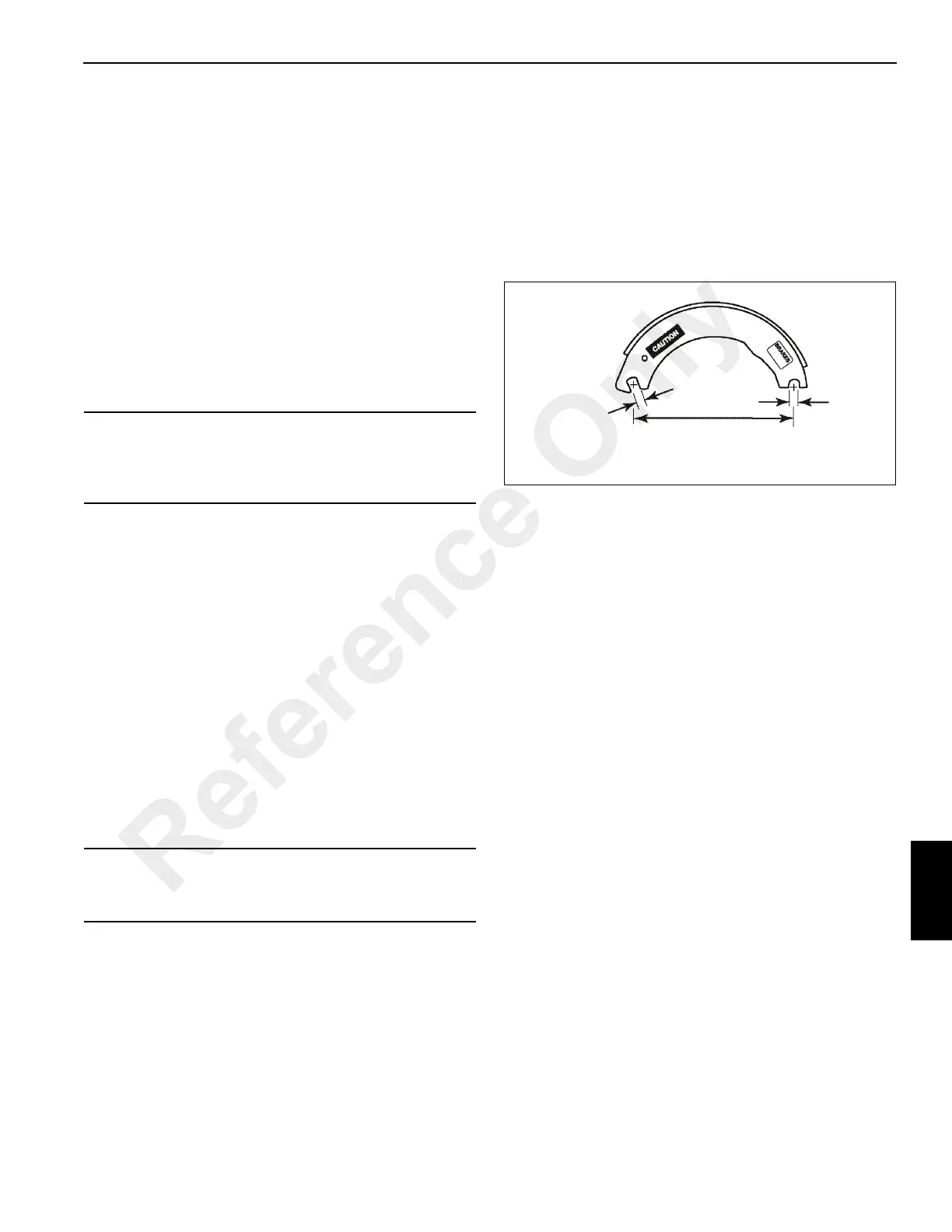

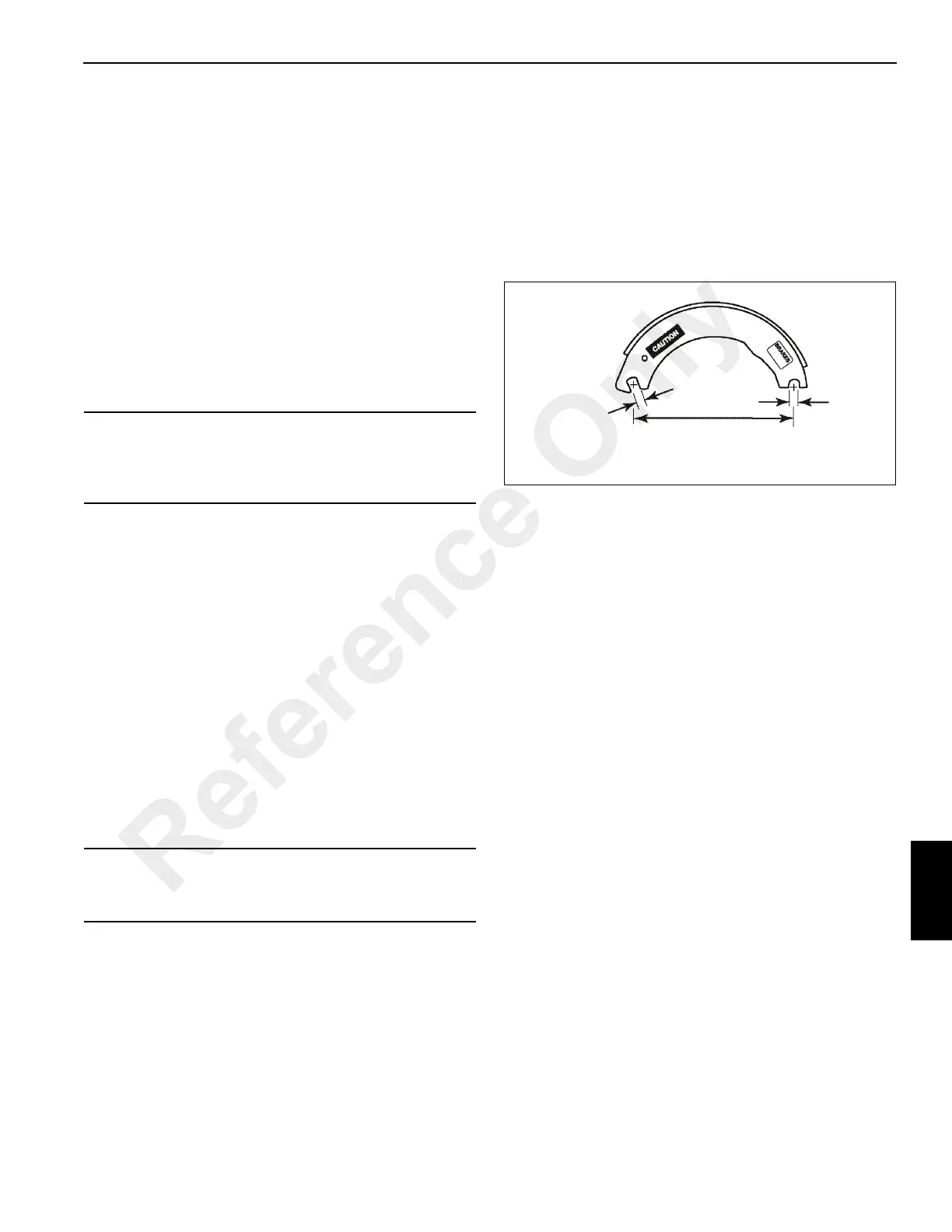

6. Anchor pin holes must not exceed 25.63 mm (1.009 in)

in diameter. The distance from the center of the anchor

pin hole to the center of the roller hole must not exceed

32.46 cm (12.779 in). Replace brake shoes with

measurements that do not meet these specifications

(Figure 8-18).

7. Check the linings and replace the shoes if contaminated,

cracked, or worn to less than 6.35 mm (0.25 in)

thickness at any point.

8. Each time the brake shoes are removed, check

camshaft radial play as outlined below

a. Mount a dial indicator with the plunger on the cam

head at the roller contact area.

b. Zero the dial indicator.

c. Move the cam head up and down and note the

maximum reading.

d. If play exceeds 0.9 mm (0.035 in), rebush the air

chamber bracket. Refer to Repair/Replacement in

this Section.

e. After rebushing, recheck radial play. Replace the

camshaft if play is still excessive.

9. Check the end of the camshaft for cracks and worn or

deformed splines. Replace as necessary.

10. Check the camshaft bushing journals for wear or

corrosion. If the camshaft shows visible wear or if

roughness is felt in the journal, replace the camshaft.

11. Check the camshaft head for brineling, cracking or flat

spots. Replace the camshaft if a ridge can be felt

between the worn areas and surface of the cam head.

NOTE: The camshaft bushings and seals are mounted in

the air chamber bracket assembly.

12. Check the camshaft bushings for deterioration or wear.

The inner surface must be smooth. Replace the bushing

if surface is rough or abrasive.

CAUTION

Oxidation and dirt on the outside of brake drum acts as an

insulator and may hinder heat dissipation. Remove with a

wire brush.

CAUTION

Do not use drum if it exceeds maximum diameter or run-

out specifications.

FIGURE 8-18

Anchor End

Cam End

32.46 cm (12.779 in)

25.63 mm

(1.009 in)

Max.

6597-4

25.63 mm

(1.009 in)

Max.

Reference Only

Loading...

Loading...