8-26

Published 01-29-2014, Control # 496-00

UNDERCARRIAGE TMS800E SERVICE MANUAL

13. Check the grease seals and replace if nicked, cut, or

distorted.

14. Check the air chamber bracket for a bent, broken, or

cracked arm and welds. Replace as necessary.

15. Check the air chamber bracket mounting studs for

looseness, damaged threads, or bent studs. Replace as

necessary.

16. Check the air chamber for leaks, cracked housing, bent

push rod, loose clamp ring, clogged vent holes, or loose

air fittings. Repair or replace as necessary.

17. If the air chamber is replaced or repaired, check the

distance from the clevis pin hole centerline to the air

chamber face. Reference Automatic Slack Adjuster in

this Section for adjustment.

18. If a new air chamber is installed, ensure that the cutoff

push rod does not project too far into the clevis.

Minimum clearance from the clevis centerline to push

rod end is 22.2 mm (0.875 in).

19. Check air chamber clevis pin for cracks and wear.

20. Check the automatic slack adjuster. Reference

automatic Slack Adjuster this Section.

Repair/Replacement

Routinely replace lower cost items such as springs, seals,

bushings, and heavily worn parts. Damage caused by failure

of worn parts is much more expensive than the cost of the

parts.

Camshaft bushing and/or grease seal replacement is as

follows:

1. Remove the air chamber bracket.

2. Drive out the old bushing and grease seal with a suitable

driver.

3. Clean and inspect the air chamber bracket. Reference

Inspection in this subsection.

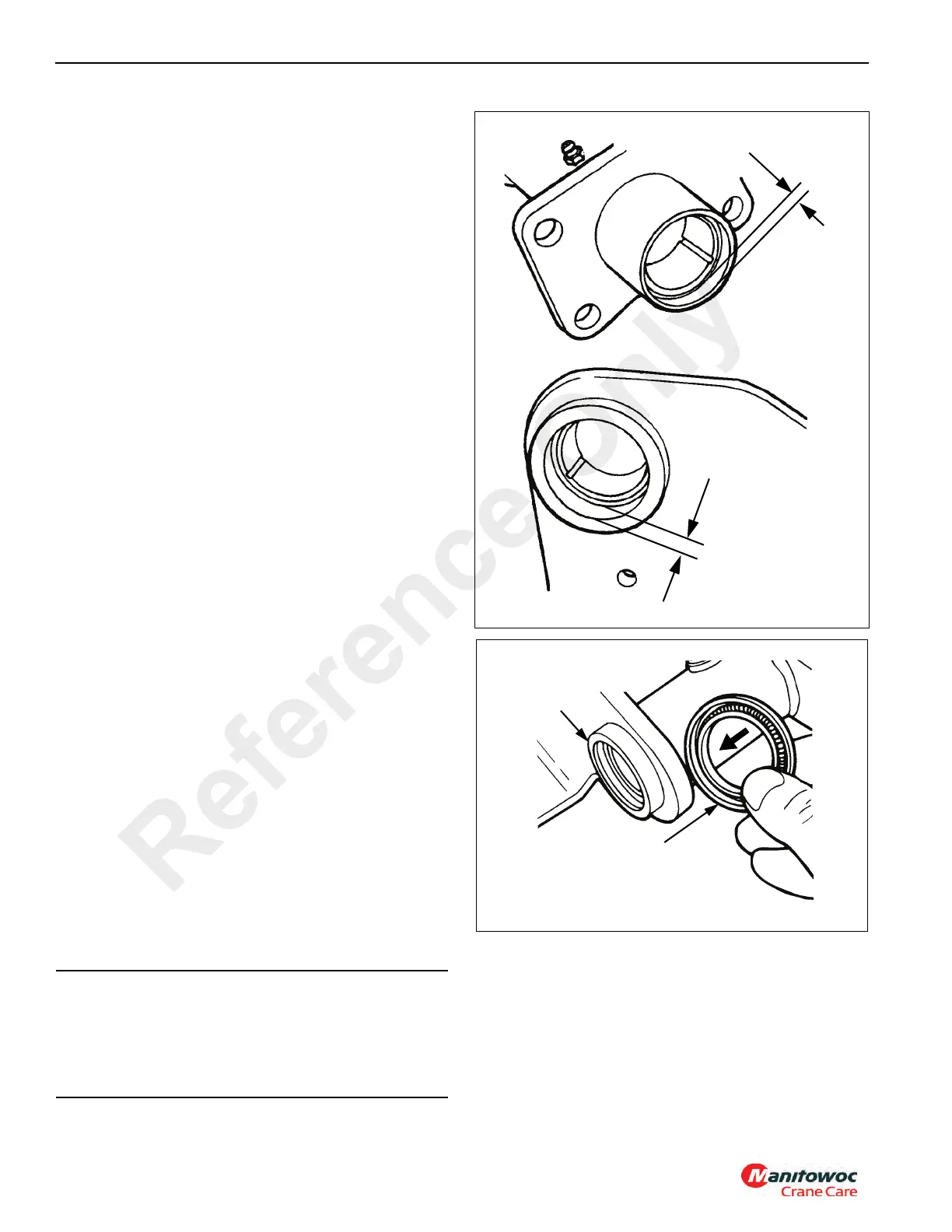

4. Install the new bushings in the air chamber bracket with

a piloted driver. Both bushings are nonmetallic and are

labeled on one end. Install them with the labeled ends

facing each other. The cam head end is recessed 7.1

mm (0.281 in) and the slack adjuster end is recessed

17.5 mm (0.688 in) from the ends of the tube (see

Figure 8-19).

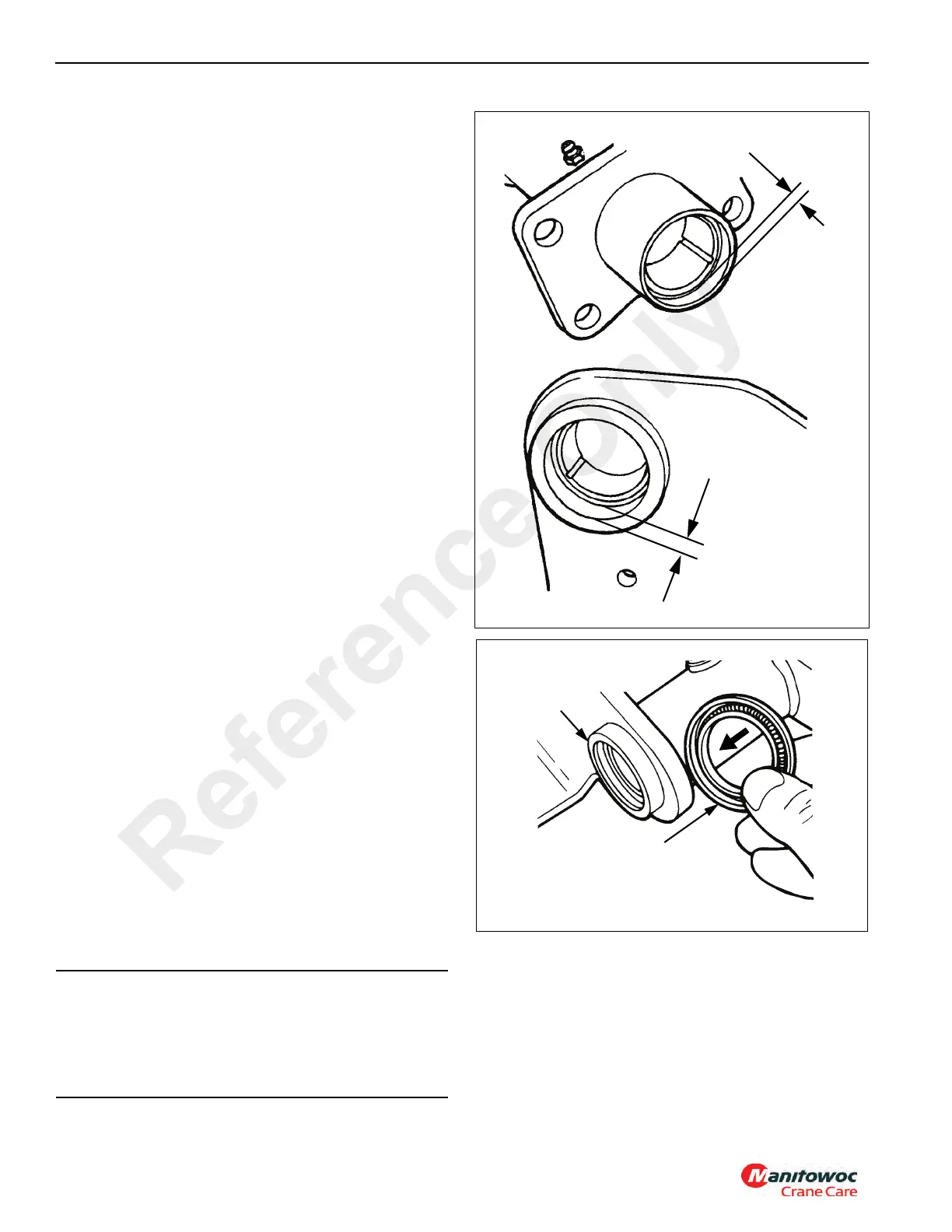

5. Install new grease seals with a piloted driver so the seals

are flush with the end of the air chamber bracket tube

(see Figure 8-20).

CAUTION

Seals must be installed with the lip side (spring side) of

both seals facing toward the slack adjuster end of the

bracket. Improperly oriented seals may allow grease to

exit the camshaft head end of air chamber bracket and

contaminate lining material.

At slack adjuster end,

recess bushing 17.5

mm (0.687 in)

At cam head end, recess

bushing 7.1 mm (0.281 in)

FIGURE 8-19

Install seals flush

with end of tube.

Lip side of both seals

must face toward slack

adjuster end of bracket

FIGURE 8-20

Reference Only

Loading...

Loading...