WRS – Installation Manual

5. MAINTENANCE

5.1 Cleaning and checks

To obtain always the best performances of the measuring system it is convenient to clean and check it

regularly.

Table 5-1 shows the maintenance operations to be performed on the WRS System, with an indication of the

intervals.

WARNING

Before carrying out maintenance work, setup the Customer's logic so as to guarantee operator

safety. Any machine movement which may injure the operator must be inhibited.

Table 5-1. Maintenance.

DEVICE CHECK - PROCEDURE FREQUENCY

WRP - WRTS

Cleaning the glass. Periodically, based on the conditions of use.

WRI

[

N.B.:

It is extremely important to en

sure the radio system glass panels remain free from traces of

coolant and/or chips

since all electrically conductive, or partially conductive, substances can

reduce the communication range.

5.2 Checking the integrity of wiring

Periodically you have to check the integrity of the cables and whether the electric terminals are tight.

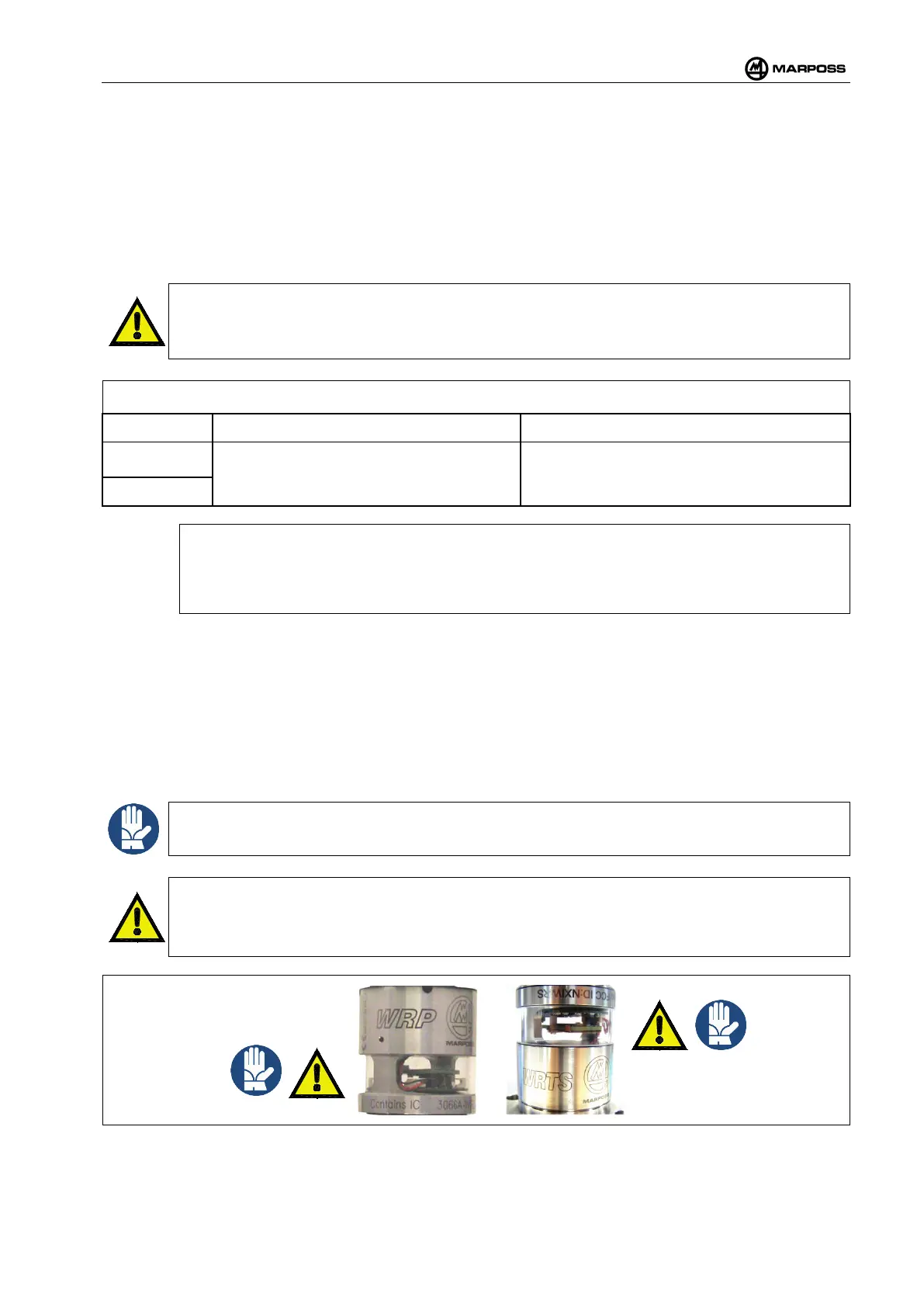

5.3 Accidental breakage of glass

Incorrect machine manoeuvres or high energy impacts may result in damage to the glass panel on the WRP

- WRTS transmitter.

USE OF GLOVES OBLIGATORY

Avoid contact with sharp edges and use cut-proof safety gloves.

ATTENTION

The WRP - WRTS transmitter should not be used if the glass has been damaged.

Marposs Customer Service to have the glass replaced.

Figure 5-1. WRP - WRTS Transmitter

Loading...

Loading...