Chapter Four: Analog and Digital Interfaces Analog Interface Input and Output Options

30

5. In selecting the appropriate type and wire size for cables, consider:

Voltage ratings.

Cumulative I

2

R heating of all the conductors (keep them safely cool).

IR drop of the conductors, so that adequate power or signal voltage gets to the device.

Capacitance and inductance of cables that handle fast signals (such as data lines or stepper motor

drive cables).

Some cables may need internal shielding from specific wires to others.

Analog Interface Input and Output Options

These analog I/O types are included for future reference. They were not available at the time this

manual was written.

The G-SERIES analog I/O MFC is available with either a 9 pin D male connector or a 15 pin D male

connector for providing power and signal I/O.

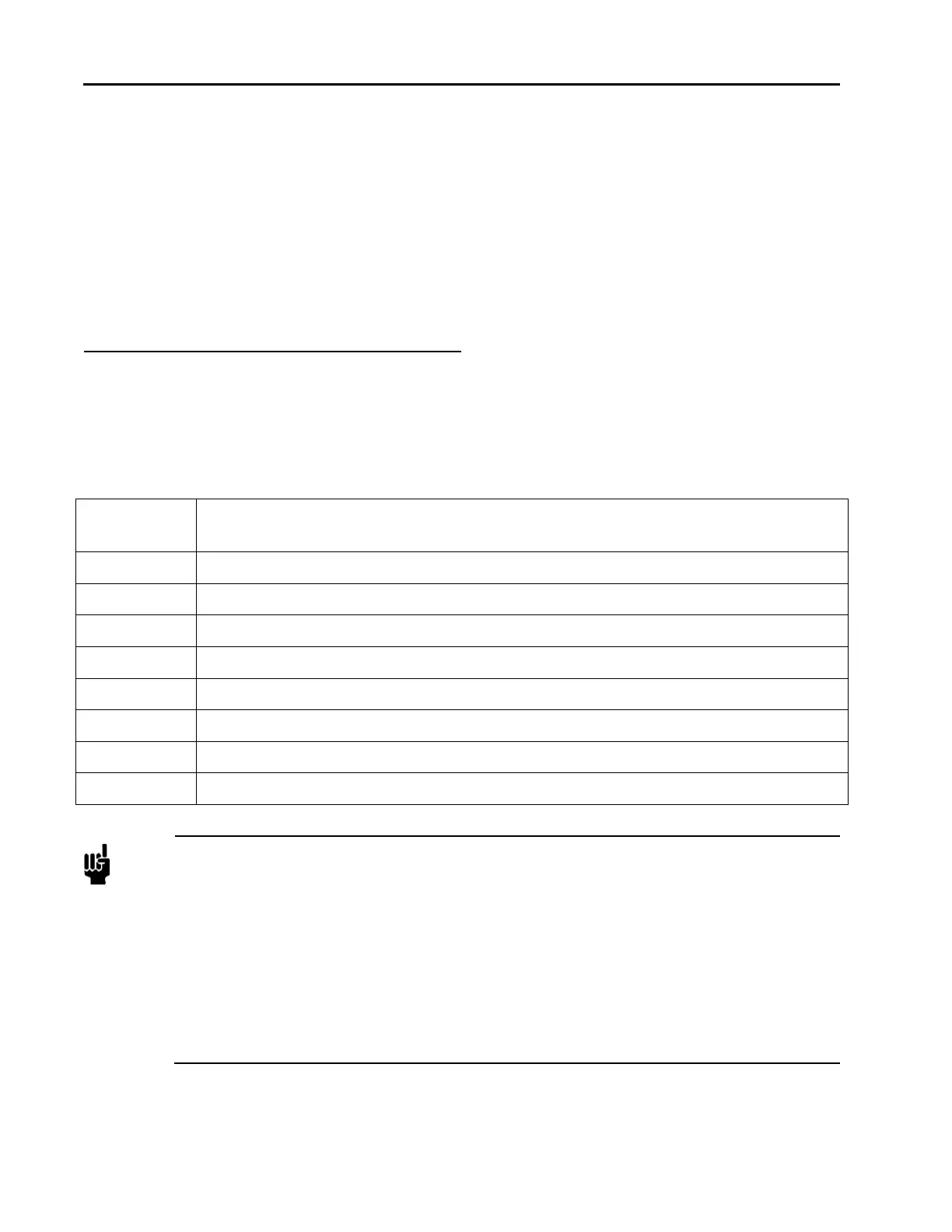

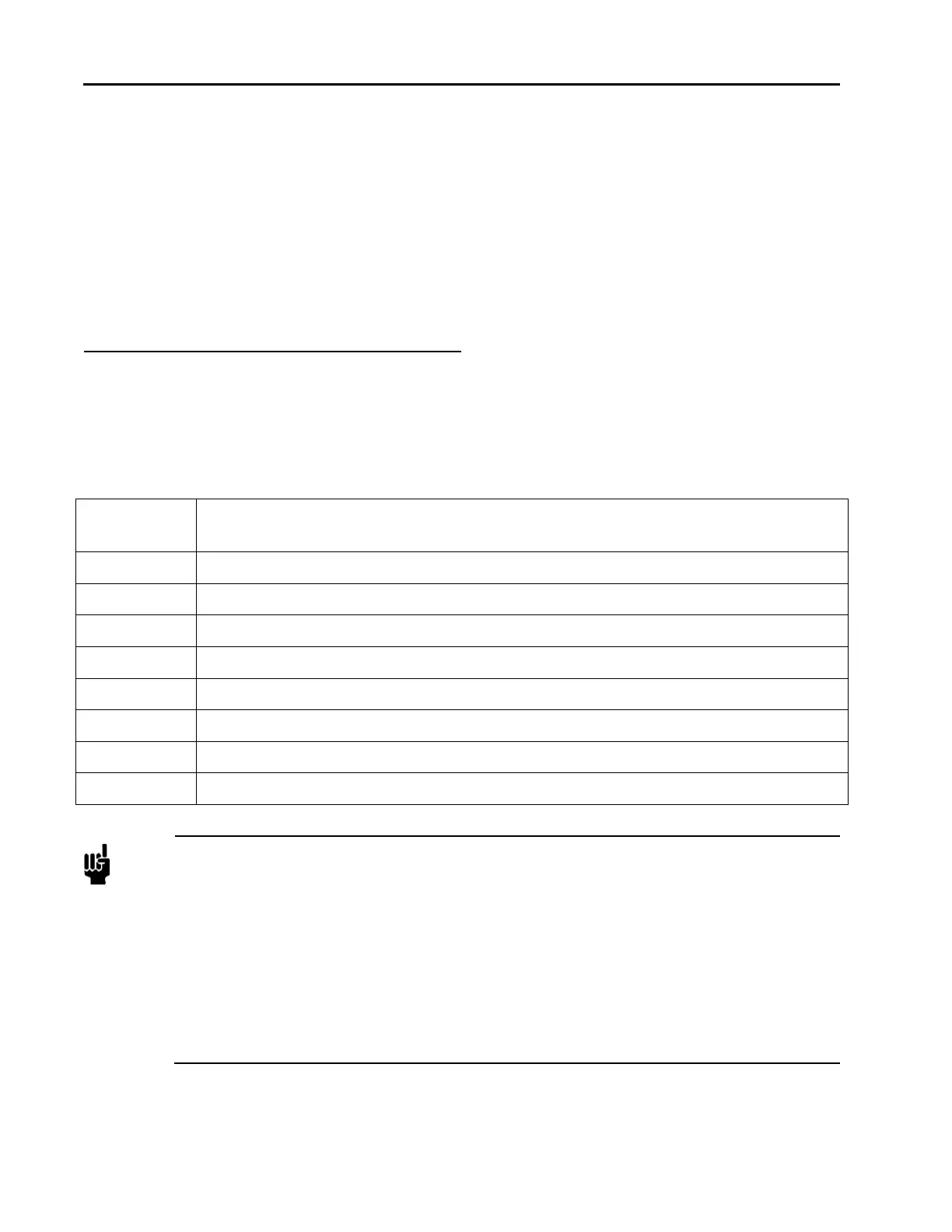

Table 8: Analog Interface Voltage I/O (0 to 5 VDC) – 9 Pin D Male Pinouts – Model Code A

Pin 1 Valve Open/Close: Apply +5 to+15 VDC to Open; Pull to ground or apply -5 to -15

VDC to Close.

Pin 2 Flow Output Signal, 0 to5 VDC (into high impedance load, minimum 10K-ohm)

Pin 3 +15 to +25 VDC :Power

Pin 4 Power Common

Pin 5 No Connection

Pin 6 Setpoint Input, 0-5 VDC

Pin 7 Signal Common

Pin 8 Signal Common

Pin 9 Valve Test Point

Notes

1. Chassis ground is not available on a separate pin. Instead, it is carried out through the cable

shielding. Be sure that the connector on the other end of the cable is properly grounded to its

chassis ground.

2. The 0 to 5 VDC flow signal output comes from pin 2 and is referenced to pin 7 (signal

common).

3. Use any appropriate 0 to 5 VDC input signal of less than 1K ohm source impedance

referenced to pin 7 as the setpoint signal to pin 6.

4. A signal common line MUST be connected to the power common line at either at the tool

end or at the MFC 15 pin D connector end of the cable to avoid setpoint/readback offsets.

DO NOT connect a signal common line and the power common line at both ends of the

cable as this will result in ground loops.

Loading...

Loading...