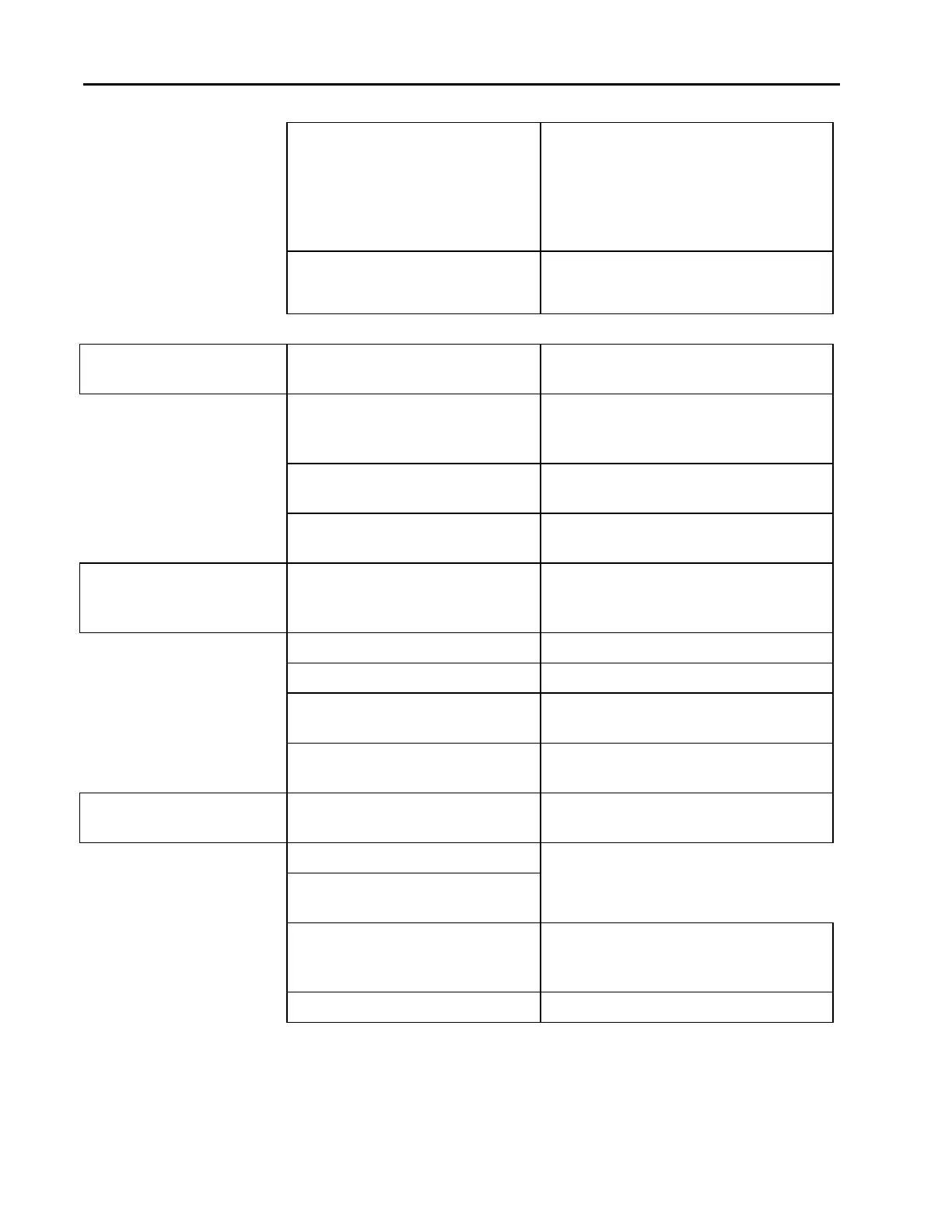

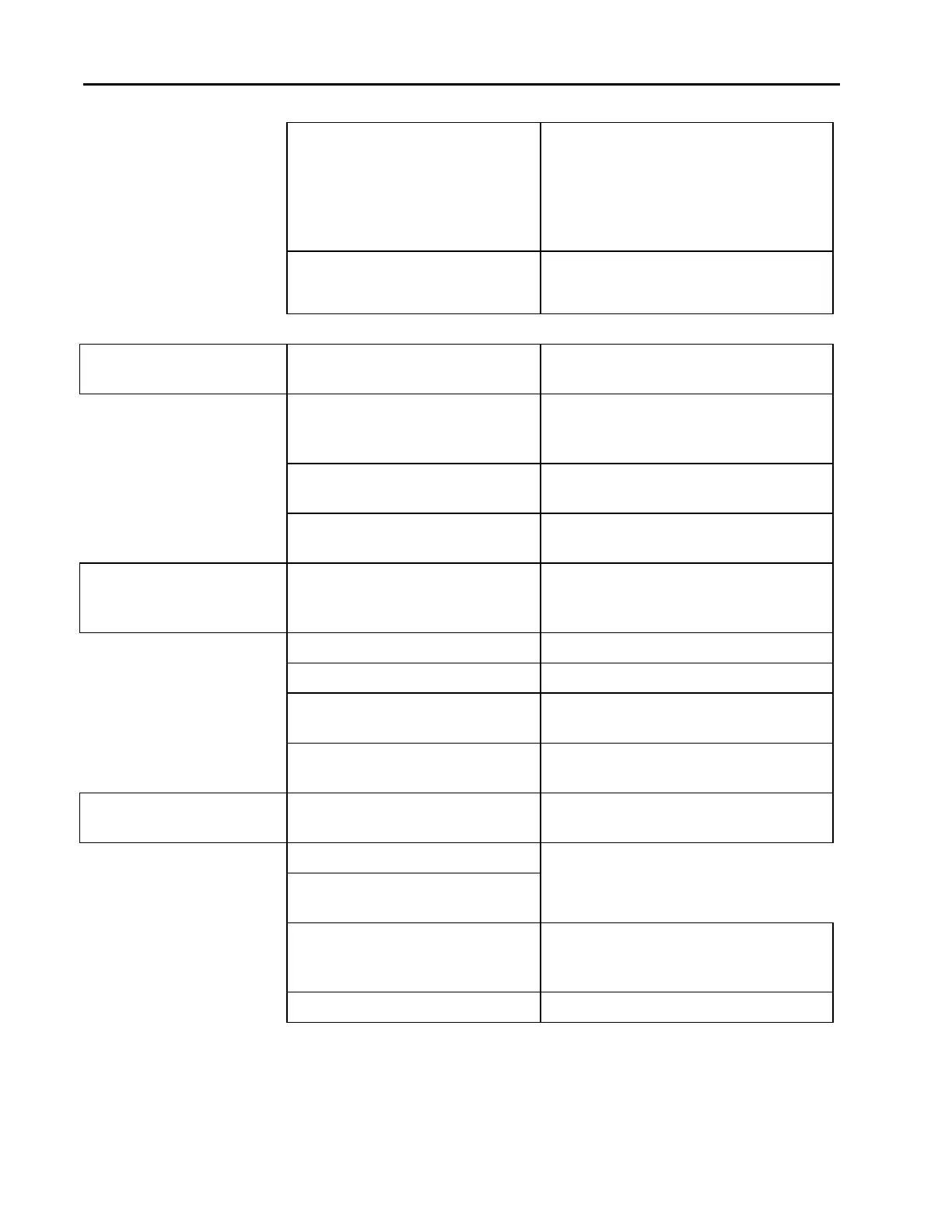

Chapter Eight: Troubleshooting Troubleshooting Chart

74

MFC clogged sensor Run MFC diagnostics. Verify MFC

inlet pressure, check valve current

for open valve condition and check

for gas flow downstream of MFC. If

flow present, possible clogged

sensor

MFC control circuit failure Run MFC diagnostics. If error

results, contact MKS service center.

MFC shows output flow >

FS (overrange)

MFC valve full open Check valve current for maximum

condition

Pressure drop across MFC is

greater than specification

Measure upstream pressure &

downstream pressure. Compare to

specification.

Faulty valve control

circuit/calibration

Run MFC diagnostics using Ethernet

GUI

Possible contamination in valve

assembly

Cycle-purge MFC to clear suspected

contamination

MFC output signal does

not match setpoint

Contamination Check for partial block orifice or

sensor. Cycle purge MFC to clear

contaminant

Inlet pressure too low Increase inlet pressure

Outlet pressure too high Decrease outlet pressure

Flow signal is not properly

grounded.

Check for ground loops.

Control electronics failure,

sensor failure

Run MFC diagnostics test

MFC output signal

oscillates

Inlet pressure oscillates Check for faulty regulator

Inlet pressure too high Lower inlet pressure

Inlet pressure too high Adjust programmed inlet pressure

through Ethernet GUI.

MFC nameplate gas not same

as actual gas

Check for programmed gas using

Ethernet GUI or digital interface.

Reprogram as necessary

Faulty control circuit Run MFC diagnostic test.

Loading...

Loading...