0

Actual

ON Calibrate

Pressure sensors

bar

P sensor A1

Operation

4-60

P/N 7105144G

2008 Nordson Corporation

VersaBlue_NW

Melter (contd.)

Screen 3: Defaults, IP Address, Pressure Sensor (contd.)

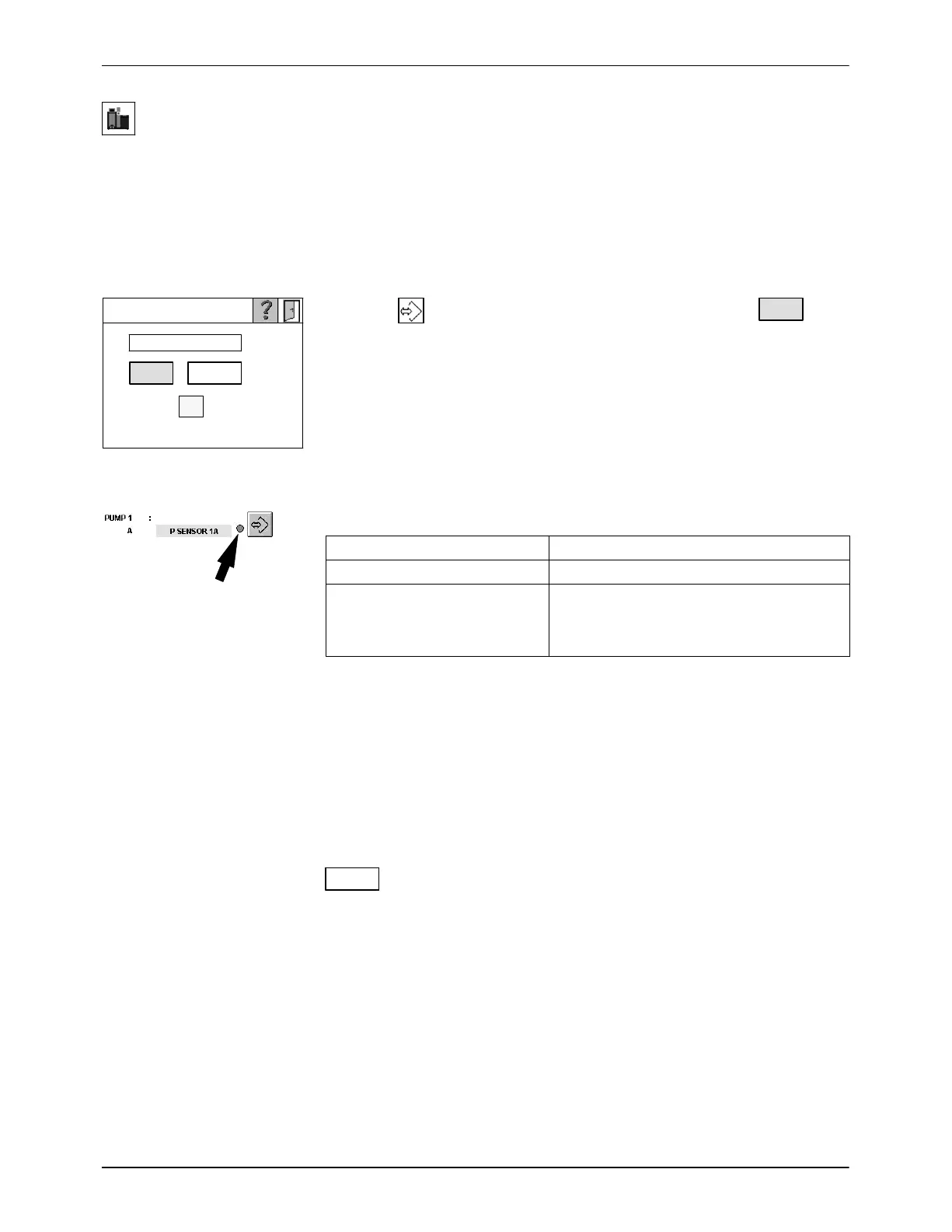

Assigning New CAN Bus Sensor

1. Connect CAN bus cable to new pressure sensor.

2. The indication lamp New sensor lights up after a short time. The new,

not yet assigned pressure sensor has been detected.

3. Select

of the desired line, then switch pressure sensor

ON

.

The pressure sensor can be switched on and off. If a pressure sensor is

switched off, it is removed from the assigned location and is available as

a New sensor after a short time.

CAUTION: Do not switch off the melter as long as the ON/OFF key

appears transparent.

Fig. 4-78 V25

4. Wait until the keys are no longer transparent.

5. Check the color of the indication lamp:

Color of the indication lamp

Meaning

Green Pressure sensor is assigned

Red Pressure sensor is defective

CAN bus to sensor is interrupted

CAN bus is faulty

6. Repeat steps for every new pressure sensor until all have been

assigned.

Calibrating Pressure Sensor

NOTE: To calibrate the sensor, the melter must be heated to processing

temperature and may not be pressurized (relieve pressure if necessary;

refer to section Installation).

Calibrate

Perform nullification. Nullification should be performed even if 0 bar

is displayed as the actual value; internal calibration is more precise.

Loading...

Loading...