1 2

Maintenance

5-20

P/N 7105144G

2008 Nordson Corporation

VersaBlue_NW

Pressure Sensor

Available only with options Pressure display and Pressure control.

WARNING: System or material pressurized. Relieve pressure. Failure to

observe may result in serious burns.

Cleaning Separating Membrane

WARNING: Hot! Risk of burns. Wear appropriate protective

clothing/equipment.

CAUTION: Clean the separating membrane (arrow, Fig. 5-21) with

particular care. Never use hard tools.

Whenever possible, remove material residue only with a cleaning agent

recommended by the material supplier. Thermoplastic substances such as

hot melt adhesive may need to be heated with a hot air fan and then

carefully wiped off with a soft cloth.

Fig. 5-21

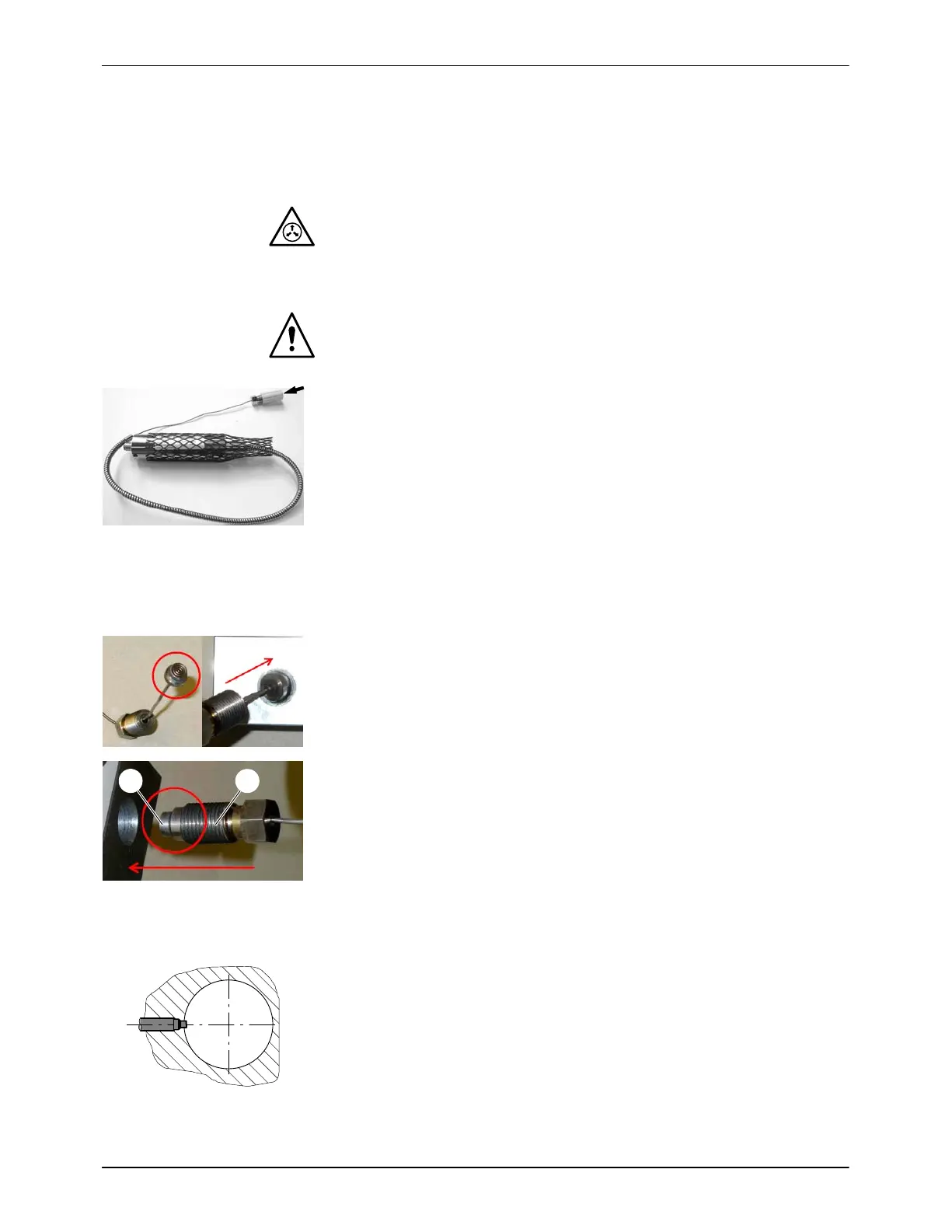

Screwing in Pressure Sensor

NOTE: The unit part and the pressure sensor should be at or near room

temperature before the pressure sensor is screwed in firmly.

1. Apply high temperature grease to the thread (Refer to Processing

Materials).

2. Only screw pressure sensor into a very clean hole.

NOTE: Do not tilt or jam when screwing into place.

Refer to Fig. 5-22: Top illustration wrong; bottom correct: The screw plug (2)

is used as a guide for the separating membrane (1).

Recommended installation torque: 13.6 Nm / 120 lbin

Max. installation torque permitted: 56 Nm / 500 lbin

Fig. 5-22 Top wrong −

bottom right

CAUTION: If the material hole is to be cleaned with a hard object, the

pressure sensor must first be removed; otherwise the separating membrane

would be damaged.

Fig. 5-23 Principle drawing

Loading...

Loading...