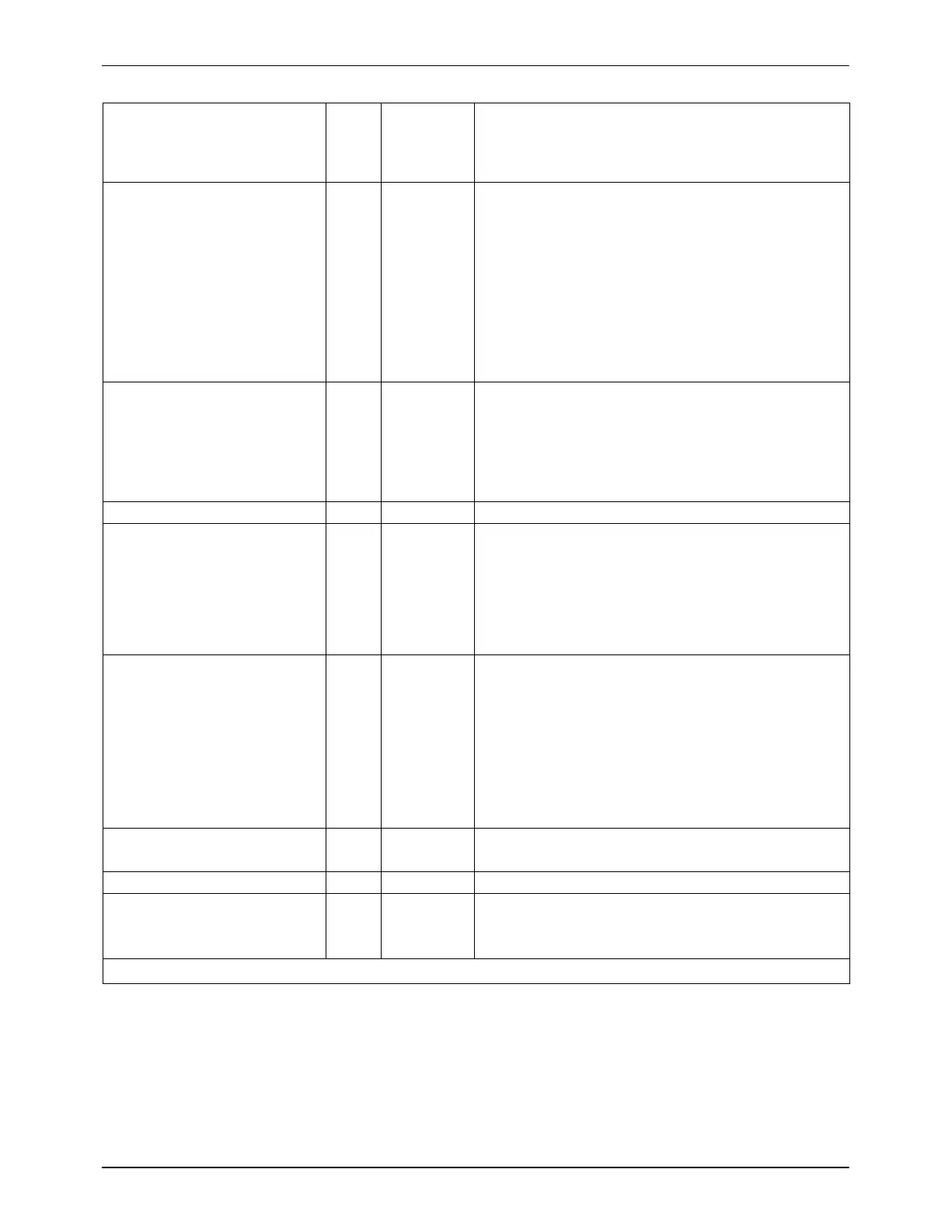

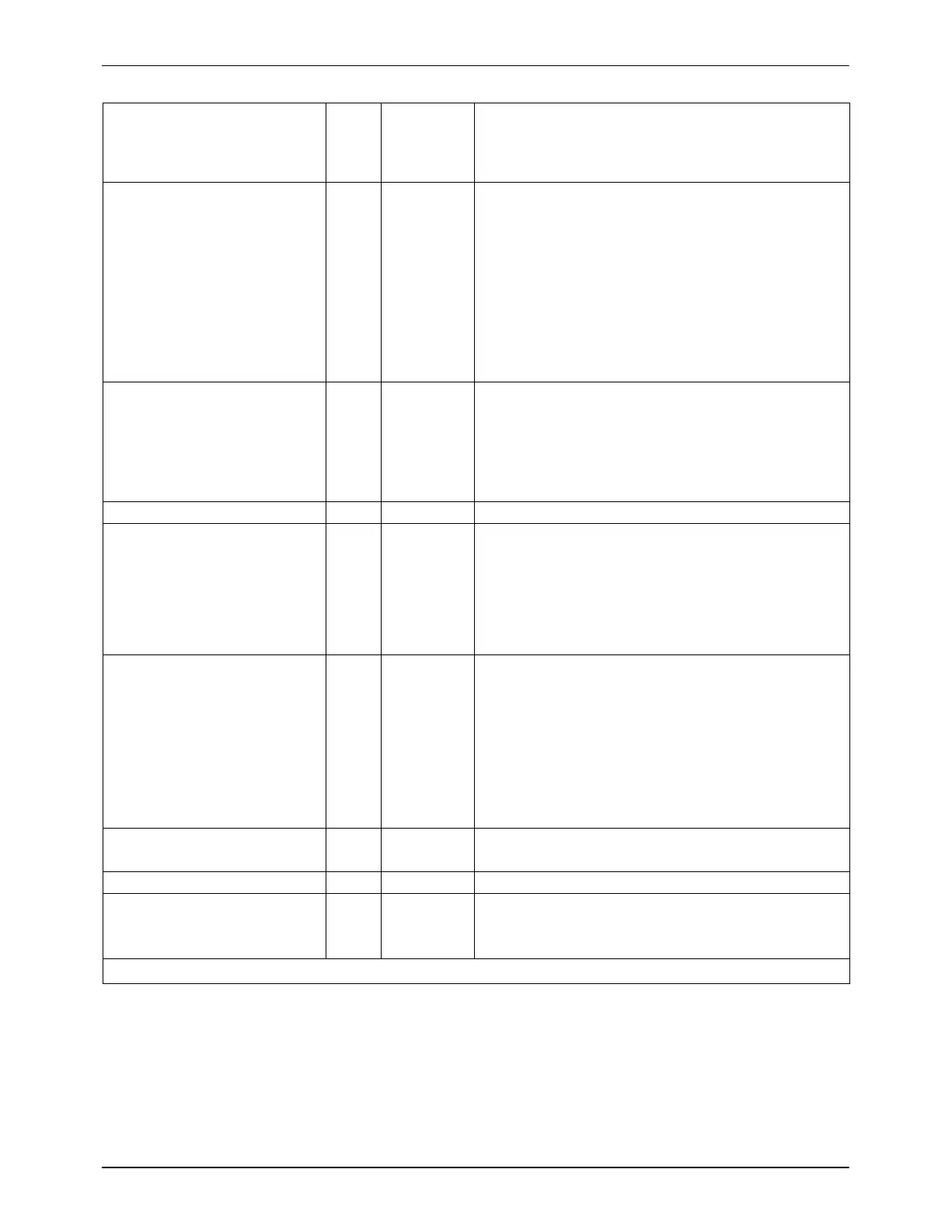

Options

10-3

P/N 7105144G

2008 Nordson Corporation

VersaBlue_NW

Option in configuration

code

Box Also

available

as

accessory

Description

Safety valve with display 14 − O: The mechanical safety valve with Reed switch

replaces the installed mechanical safety valve.

There is no pressure control valve.

If filters or application nozzles are blocked, the

material pressure increases. The safety valve

opens at 85 bar, and the material flows back into

the tank.

The Reed switch on the safety valve generates an

electrical signal that can be emitted as a fault or a

warning.

Pressure display 15 − A: One pressure sensor per pump stream

(double-stream pumps are equipped with two

pressure sensors).

The melter outlet pressure is displayed and

monitored. Alarms for underpressure and

overpressure are displayed.

Level display 16 − L: Level sensor in tank for analog level display

Level display and filling valve 16 − B: Level control (Ni120)

C: Level control (Pt100)

Level sensor in tank for the analog level display

and the filling signals for a filling valve.

Automatic tank filling is performed e.g. by a bulk

melter connected to the filling valve with a hose.

Level display and filling valve

and overflow protection

16 − P: Level control (Ni120) with overflow protection

D: Level control (Pt100) with overflow protection

Level sensor in tank for the analog level display

and the filling signals for a filling valve.

Automatic tank filling is performed e.g. by a bulk

melter connected to the filling valve with a hose.

Additional level sensor in tank for separate overflow

protection

Level display (fixed

measuring points)

16 − F: The level sensor measures the presence of

material at five different fixed measuring points.

Light tower 17

W: Four colors. Indicates operating mode of melter.

Main switch 18 − 1: red-yellow, 4-pin

2: black, 3-pin

3: black, 4-pin

continued

Loading...

Loading...