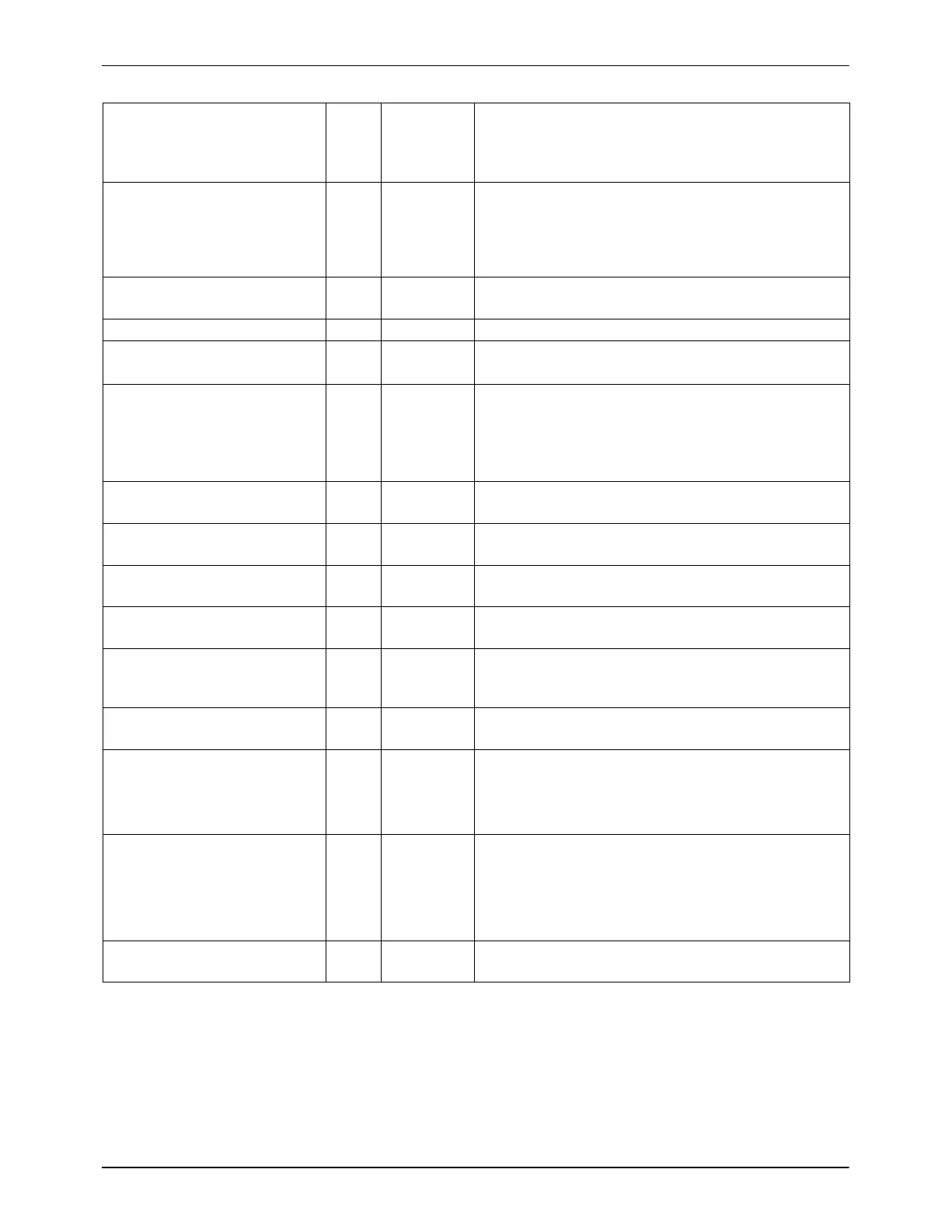

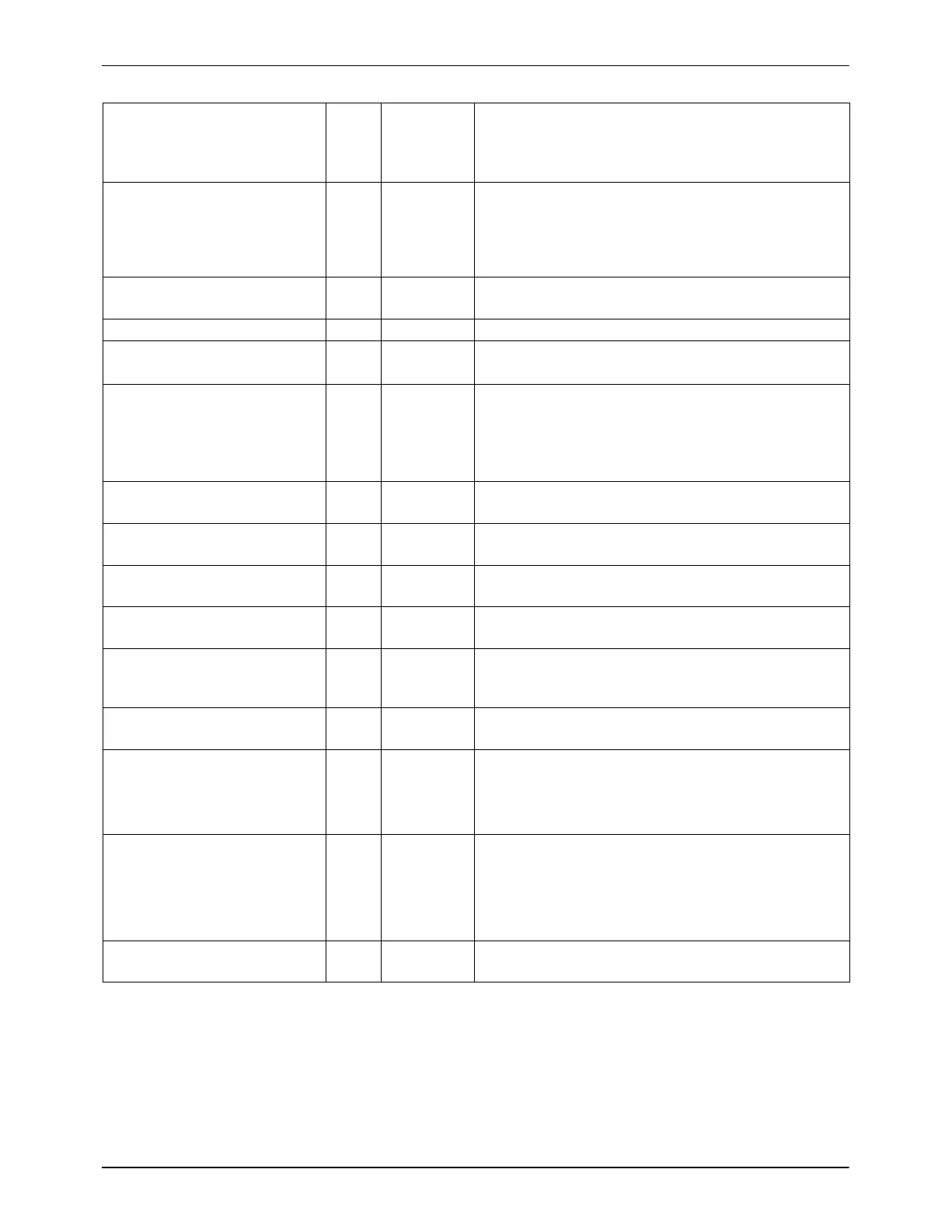

Options

10-4

P/N 7105144G

2008 Nordson Corporation

VersaBlue_NW

Option in configuration

code

Box Also

available

as

accessory

Description

Host communication 19 − D: PROFIBUS DP

N: ControlNet

E: EtherNet/IP

X: Standard IPC

Separate line speed signal

inputs

20 − K: Every motor receives its own line speed signal.

Casters 21

C: To move melter; two can be locked

Inert gas equipment 22 − G: Used to blanket tank contents with inert gas.

This is needed when processing certain materials.

Filter cartridge / safety valve 23

C: 0.8 mm filter with 85 bar safety valve

D: 0.2 mm filter with 100 bar safety valve

G: 0.8 mm filter with 100 bar safety valve

X: 0.2 mm filter with 85 bar safety valve

Spare 24 −

26

− −

Drain valve 27

D: The drain valve is used to quickly remove the

material from the tank.

Inputs for external pressure

display

28

#: The unit can receive and process signals from

external pressure sensors.

Heat exchanger 29 − E: The heat exchanger serves to maintain a

constant temperature in the electrical cabinet.

Motor circuit switch

(Service or repair switch)

30 − M: Lockable motor circuit switch. Motors can be

deenergized. Additional contact for triggering by

control system.

Gun solenoid valve 31 − G: 24 V

DC

is supplied for the gun solenoid valves.

The voltage is controlled via standard I/O.

ACM Connectivity

(ACM = Auxiliary Control

Module = additional electrical

cabinet)

32 − 1: One or two separate electrical cabinet(s) (with

additional motor and temperature channels) can be

connected and controlled.

Programmable controller

(PLC)

33 − B: A-B ControlLogix with ControlNet and PanelView

C: A-B ControlLogix with EtherNet/IP and

PanelView

D: A-B ControlLogix with DataHighway

+

and

PanelView

Spare 34 −

36

− −

Loading...

Loading...