Joint Hardstop

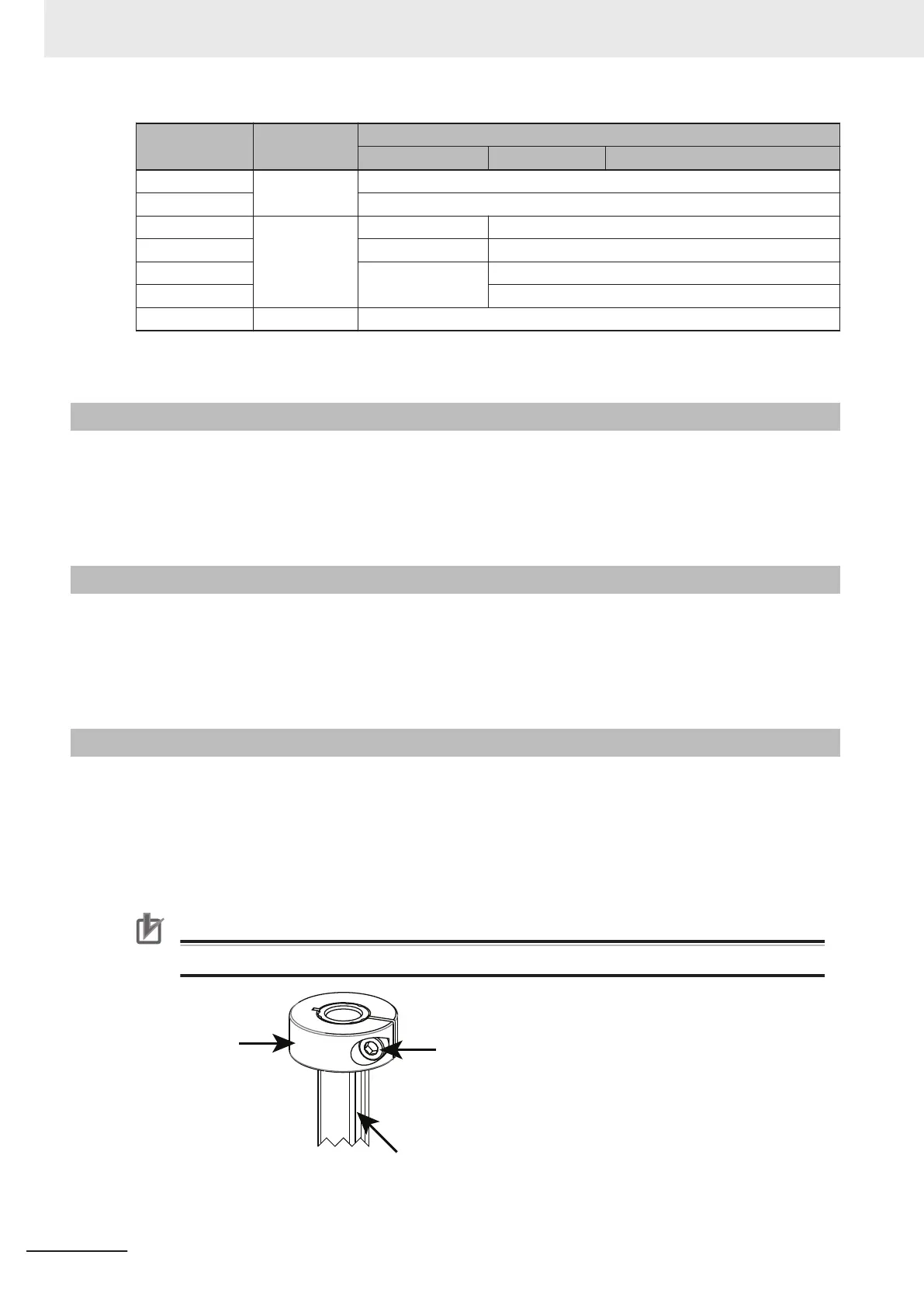

Position

Joint Limita-

tion

Range of Motion Software Limit Setting

i4-350L i4-450L i4-550L / i4-550L (350 mm Z)

1 Joint 1 -109.5°

2 +109.5°

3 Joint 2 -124° -118°

4 +124° +118°

5

See note

*1

-133°

6 +133°

7 Joint 3 5 mm from end of travel.

*1. The i4-350L model includes pre-installed hardstop screws in positions 5 and 6 to prevent base interference

with the quill. Do not remove these pre-installed hardstop screws.

3-5-1

Joint 1 Adjustable Hardstops

Use the following information when making joint 1 hardstop adjustments.

• Joint 1 hardstops require user-supplied M8 X 10 socket head cap screws, class 12.9.

• Apply Loctite thread lock type 243 or equivalent.

• Apply a torque of 17 N-m when tightening the hardstop screws.

3-5-2

Joint 2 Adjustable Hardstops

Use the following information when making joint 2 hardstop adjustments.

• Joint 2 hardstops require user-supplied M8 X 10 socket head cap screws, class 12.9.

• Apply Loctite thread lock type 243 or equivalent.

• Apply a torque of 17 N-m when tightening the hardstop screws.

3-5-3

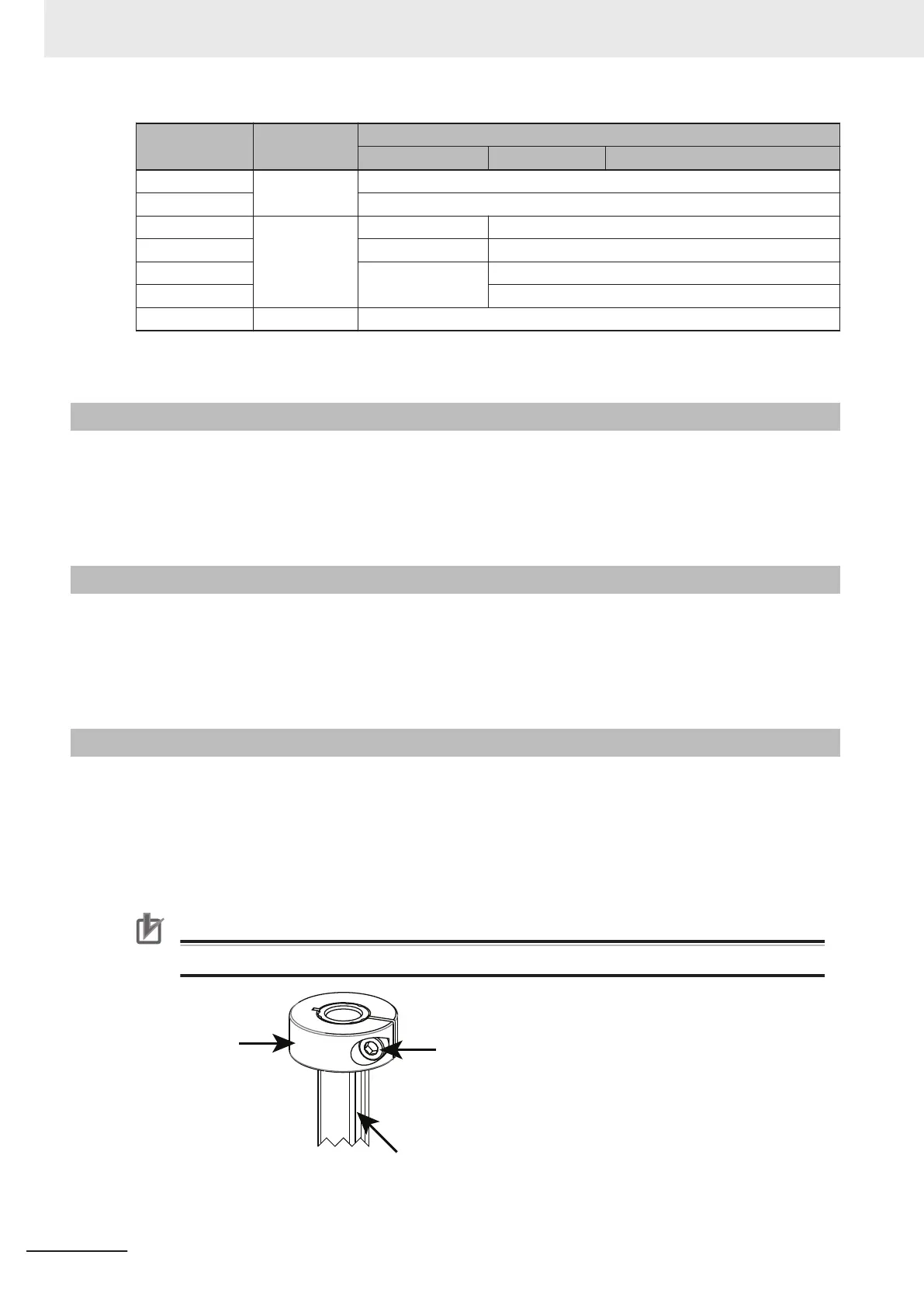

Joint 3 Adjustable Hardstop

The joint 3 down stroke can be limited by sliding the clamp collar down the z-axis quill to a lower posi-

tion.

The following tools are required when adjusting the joint 3 hardstop.

• 4 mm hex bit

• Torque wrench

• Loctite thread lock type 243 or equivalent

•

Precautions for Correct Use

Never loosen or remove the quill clamp collar while the z-axis brake is released.

Clamp Collar

Socket-head

Screw

Z-axis Quill

(Top End)

3 Installation

3-8

i4L Robots User's Manual (I658)

Loading...

Loading...