IV–91

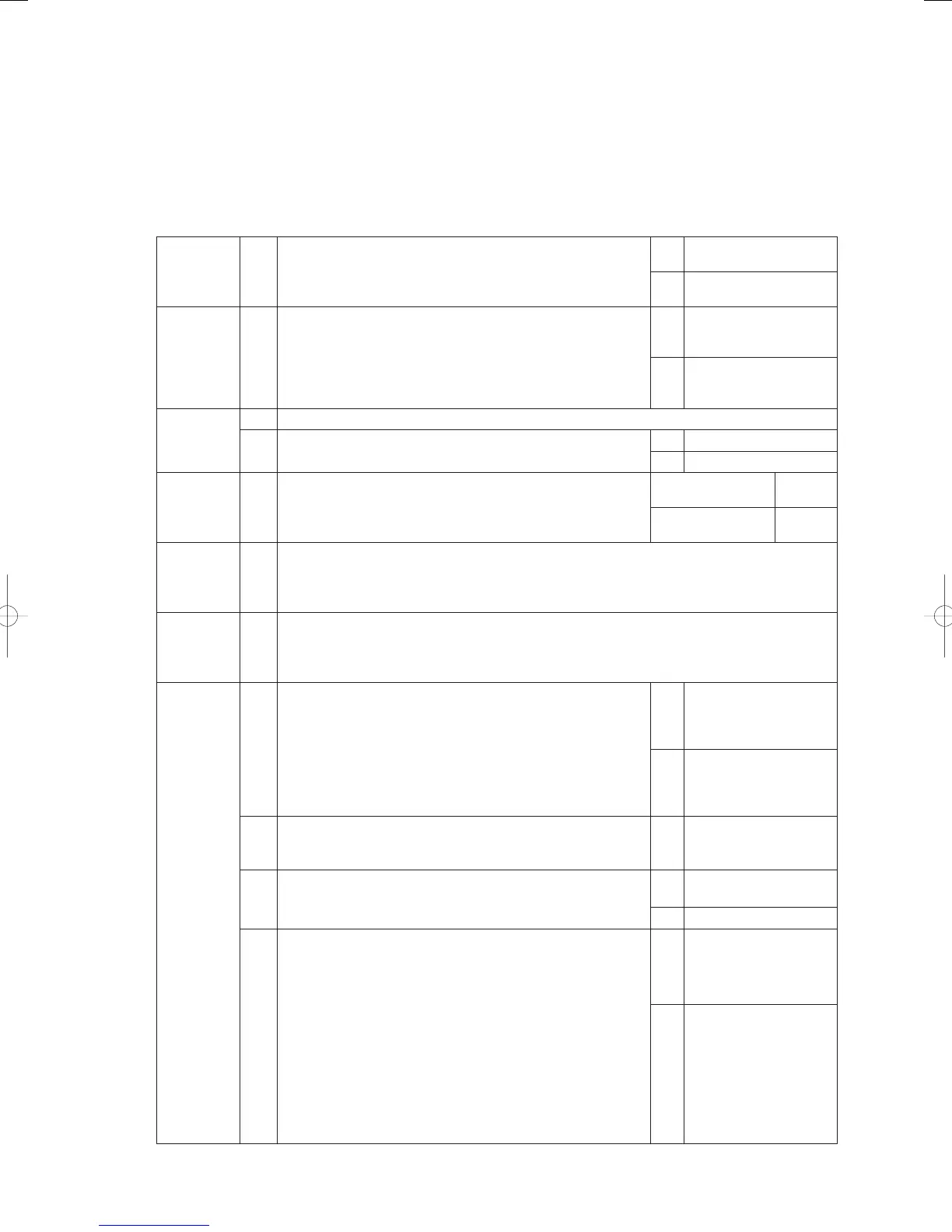

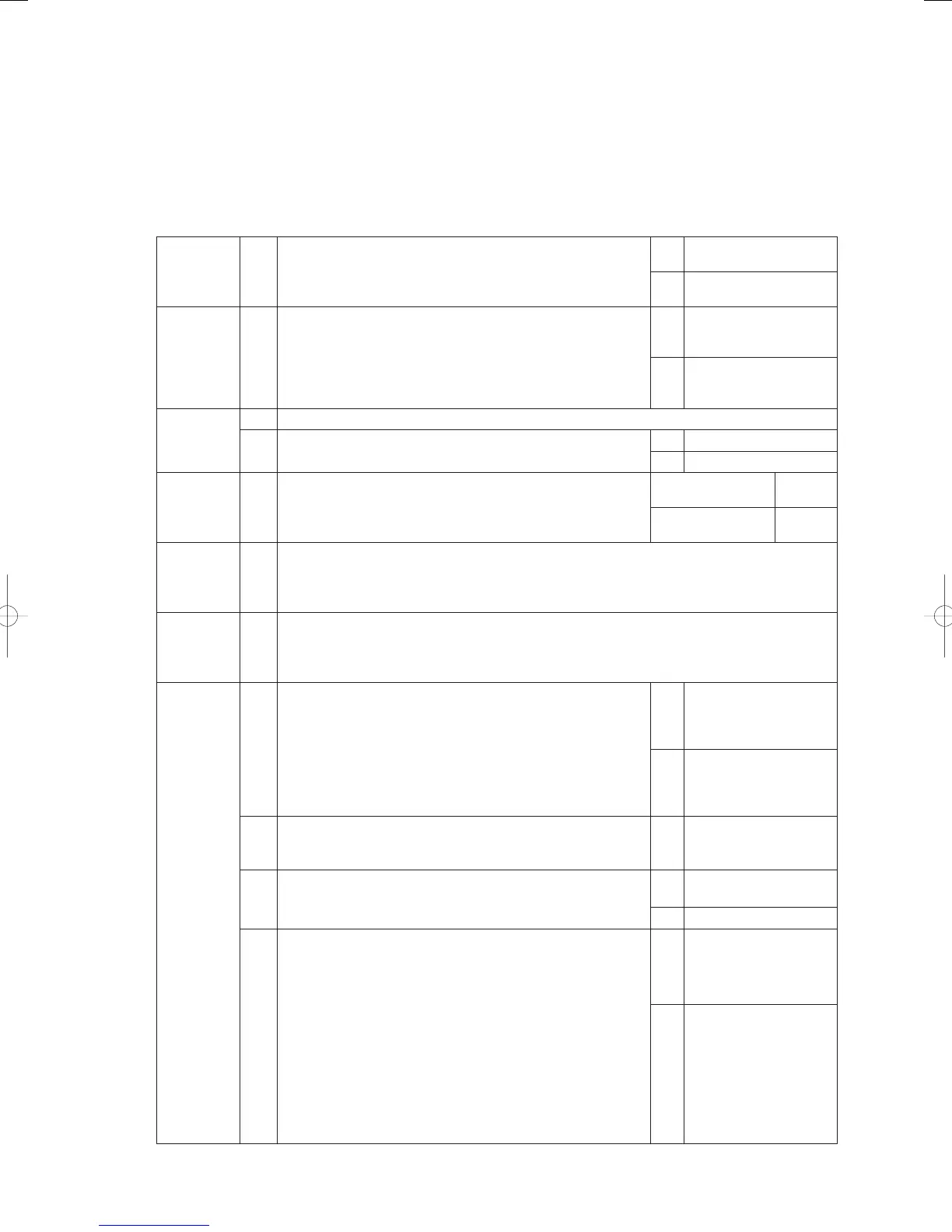

P13 Refrigerant Circuit Error (3WAY)

Error detection method

• The indoor unit outputs this warning when it determines that a compressor, outdoor solenoid valves, system

refrigerant should be inspected.

• For detailed inspection procedure, see P13 Refrigerant Circuit Fault (W MULTI).

• The system stops and there is no automatic reset when this warning is output.

Troubleshooting

1

Pressure

sensor

inspection

1-1

For adjustment of the pressure sensor, see (adjustment

procedure section F16).

OK 2-1

NG Repair

2

Inspect

system

refrigerant

2-1

Use the No. 4 test mode “v_open” (valve open) to equalize the

pressure to assess whether amount of refrigerant is extremely

low when it is lower in pressure than saturated pressure

at ambient temperature. (Assessed as out of gas when

extremely low)

Out of refrigerant gas?

Yes

Check for refrigerant

leaks and repair.

No 3-1

3

Inspect the

compressor.

3-1 Turn off the outdoor unit (be sure to do this before work)

3-2

Use the instructions in P26 Clutch Connection Fault, to adjust

operation and wiring of clutch 1 and 2. Any problems?

Yes 4 -1

No 7-1

4

Inspect

refrigerant

oil.

4-1

Replace the compressor and check the refrigerant oil in the

replaced compressor for contamination.

Not contaminated 5-1

Contaminated 6-1

5

Replace

compressor

(1)

5-1

After replacing the compressor, perform a trial operation and check the equipment. Check

completed if OK.

6

Replace

compressor

(2)

6-1 Perform a fl ashing cleaning to clean the inside of the refrigerant tubes.

7

Inspect

outdoor

solenoid

valves

7-1

Adjust outdoor solenoid valves. Use trial operation mode

to check that the solenoid valves operate normally in

each operating mode (cooling/heating) and measure

tube temperature around solenoid valves to assess. (For

information on solenoid valve operation in each operating

mode, see the sections Control functions - Operating control

in the “Outdoor unit manual.”

Does the solenoid valve operate normally?

Yes

Replace outdoor main

board

No 7-2

7-2

Adjust the power board.

Does the power board CN013 output the solenoid power

supply voltage (AC 200V)?

Yes 7-3

7-3

Any poor connection and broken wires in wiring between the

power board and the relay board?

Yes Repair wiring

No 7-4

7-4

Adjust the outdoor main board.

In No. 4 test mode when “v_open” (valve open), is there a

drive output voltage (DC 12V) from discharge valves 1-1, 1-2,

discharge valve 2, suction valve 2-1 and 2-2?

(9P (white) CN018)

Discharge valve 1-1, 1-2: between No. 3 - 9 Discharge valve 2:

between No. 4-9

Suction valve 2-1, 2-2: between No. 6 - 9

Does suction valve 1 output a drive voltage (DC 12V) during

cooling operation?

Suction valve 1: between No. 3 - 9

* Note that suction valve 1 closes when powered (the other

valves operate in the opposite way)

Yes 7-5

No

Replace outdoor main

board

GHPtroubleshooting.indbIV‒91GHPtroubleshooting.indbIV‒91 2012/11/2611:20:142012/11/2611:20:14

Loading...

Loading...