IV–23

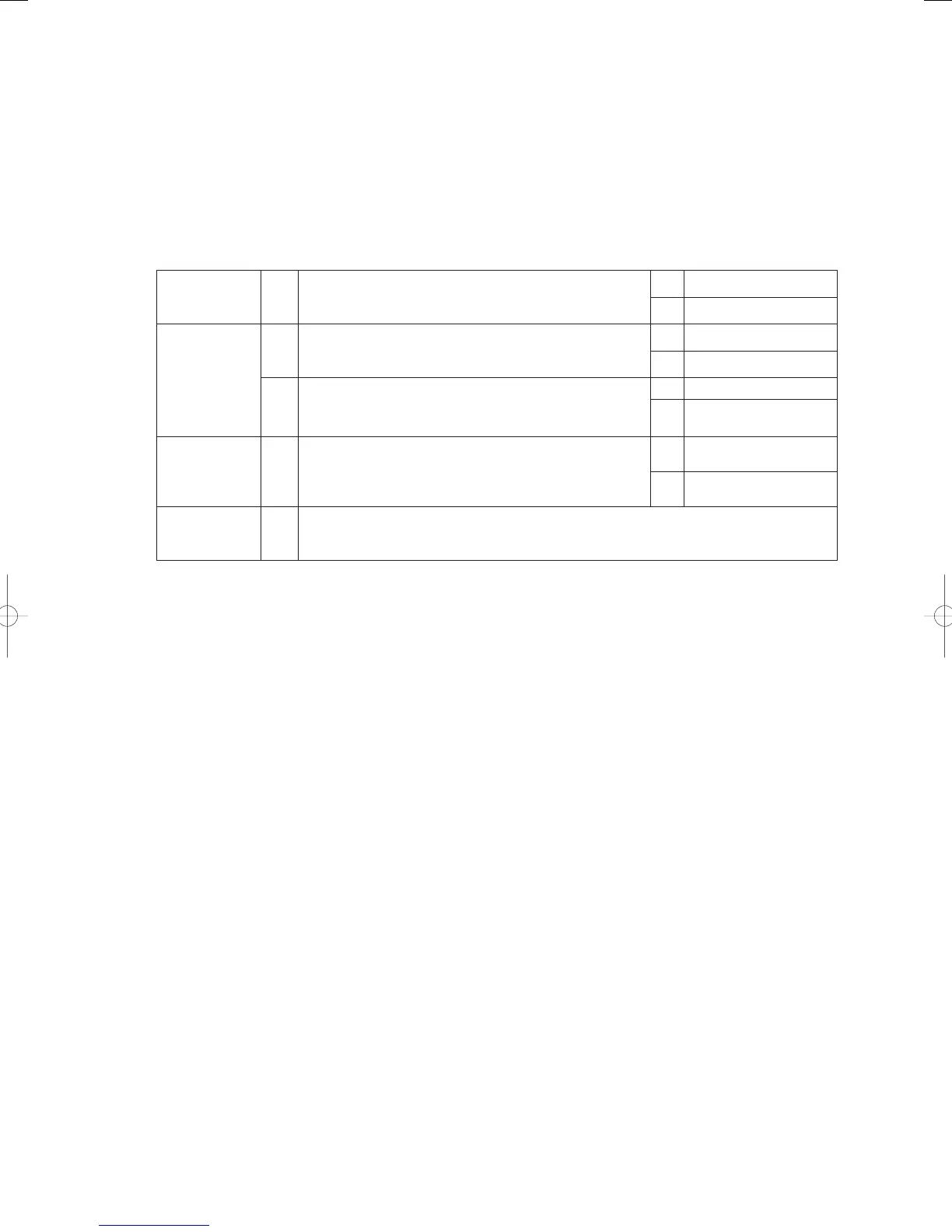

A22 Coolant Pump Error

Error detection method

Errors can be determined when coolant pump rotations and driving meet the following conditions.

• When an error is triggered once owing to the coolant pump revolutions not increasing or not being able to be

detected when the engine is started up.

• When either overcurrent, insuffi cient revolutions or excessive revolutions are detected in the coolant pump

when the engine is operating, the engine will be momentarily halted and an error fl ag set. The reason for the

engine being shut down is due to the error fl ag being triggered fi ve consecutive times in one hour.

Troubleshooting

1

Power source

check

1-1

Is the voltage being supplied to the outdoor unit normal?

(Check to see whether the voltage is too low or unstable)

Yes 2-1

No Repair the power source

2

Coolant pump 2-1

Are there any bad power cable connections when 3-phase

equipment is in use? Or, is the power cable severed or the

connection faulty?

Yes 2-2

No Repair the power cable

2-2

Is the coolant pump locked or are there any severed wires,

poor contacts or short circuits?

(Coil resistance should be around 14-18Ω for each phase.)

Yes 3 -1

No

Replace the coolant

pump

3

Coolant circuit

3-1

Has air entered the coolant circuit?

(There is a chance of air having entered the circuit if

there is a slight banging noise and pump revolutions are

fl uctuating during coolant pump operations.)

Yes 4-1

No Perform an air purge

4

Outdoor unit’s

power board

4-1

Replace the outdoor unit’s power board and keep an eye on the situation.

Replace the coolant pump if the problem reoccurs.

● For board and Electrical Wiring Diagram, see Chapter 6.

• Outdoor main board: page VI-2

• Outdoor power board: page VI-3

• Converter board: VI-4

• Indoor control board for DC motor models: page VI-5

• Outdoor Unit Electrical Wiring Diagram: page VI-6 *Reference (Electrical Wiring Diagram A-B-3)

GHPtroubleshooting.indbIV‒23GHPtroubleshooting.indbIV‒23 2012/11/2611:20:072012/11/2611:20:07

Loading...

Loading...