IV–96

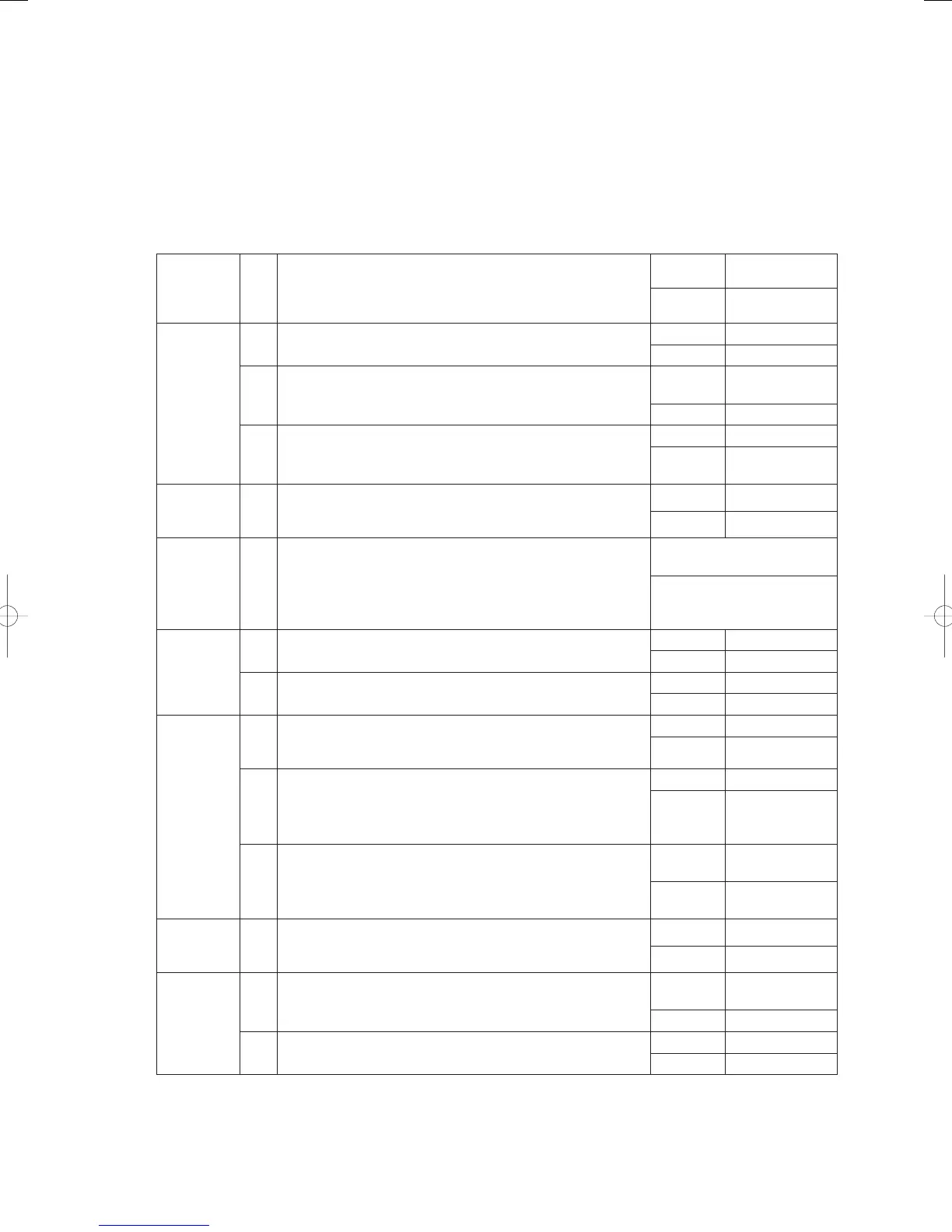

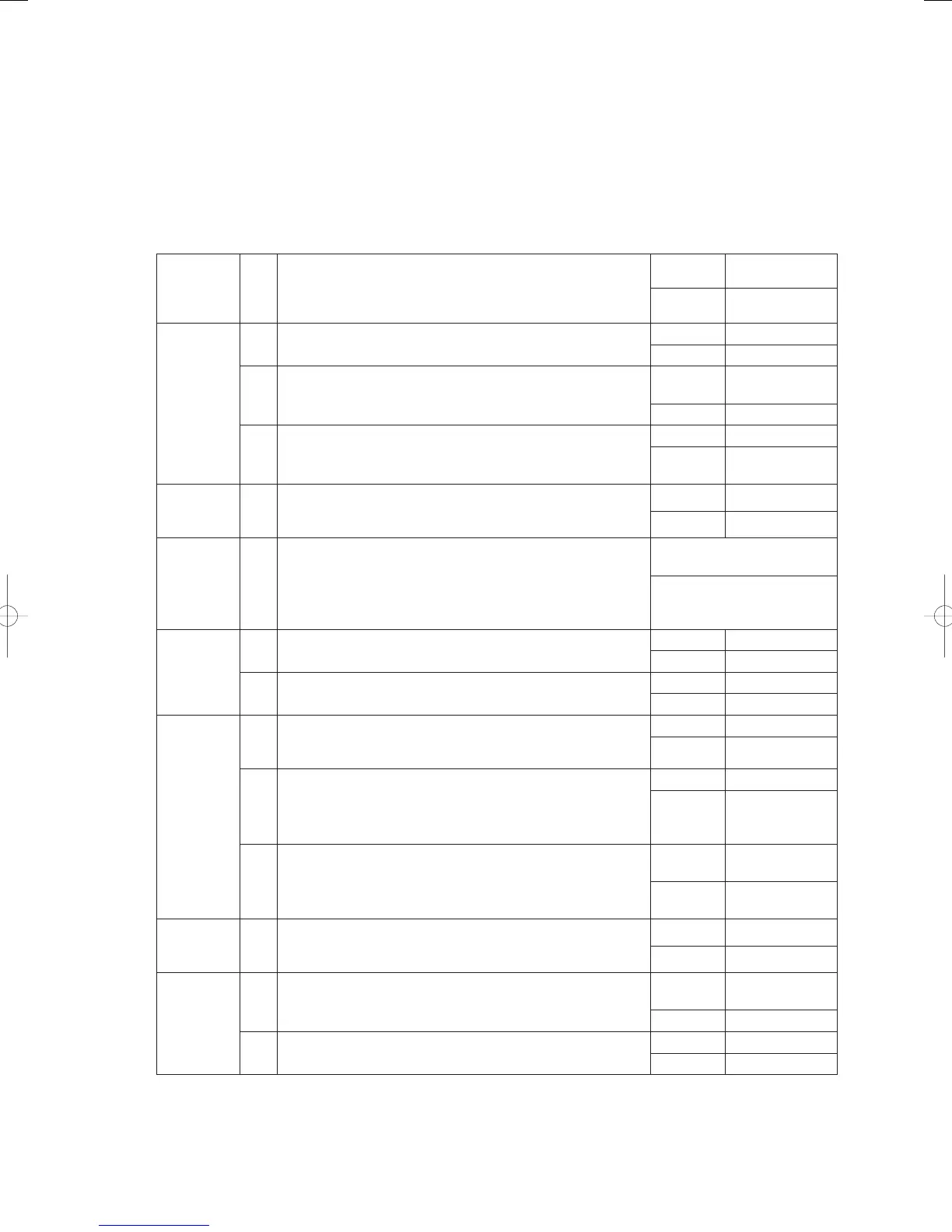

P20 Refrigerant High-Pressure Error

Error detection method

• When the high pressure sensor value ≥ 3.75 MPa during engine operation, the engine stops and an error fl ag

is set. A Refrigerant Pressure Too High fault is assumed when this fl ag has stopped the engine 5 consecutive

times in 1 hour.

• When revolution speed setting is more than minimum revolution speed and fan frequency is less than 50% of

maximum frequency, an error is not generated. (The engine stops momentarily.)

Troubleshooting

1

Cooling/

heating

mode

1-1 Operating in the cooling mode or heating mode?

Cooling 2-1

Heating 3-1

2

Outdoor

unit’s heat

exchanger

check

2-1

Is the heat exchanger clogged by foreign matter or other

debris (visual inspection)?

Yes Remove

No 2-2

2-2 Is there an air shortage?

Yes

Revise

installation

No 2-3

2-3 Is the fan on the outdoor unit operating?

Yes 12-1

No

Refer to section

P22

3

Tubing 3-1

Are there any crushed tubes, torn strainers, closed servicing

valves, or other problems? Check the temperature of the

indoor unit’s coil.

Yes Repair

No 4-1

4

Unit check

4-1

Which is connected, an indoor unit or a water heat exchanger

unit?

Proceed to 5-1 when the

indoor unit is connected

Proceed to 8-1 when the

water heat exchanger unit is

connected

5

Indoor

unit’s heat

exchanger

check

5-1 Is the air fi lter on the indoor unit clogged?

Yes Clean the fi lter

No 5-2

5-2 Is the fan on the indoor unit operating?

Yes 6-1

No Repair

6

Indoor unit’s

motor-

operated

valve check

6-1

Check the indoor unit’s motor-operated valve. Does the valve

open? (Check the indoor unit’s heat exchanger temperature

when in the heating mode.)

Yes 7-1

No 6-2

6-2

Check the indoor unit’s control board. (Is there any voltage

between No. 5 (+) and No. 1-4 (-) of the indoor unit’s control

board PMV6P (white) CN082 when the power is switched on?)

Yes 6- 3

No

Replace the

indoor unit’s

control board

6-3

Check the motor-operated valve coil. (Does a resistance of

approximately 46 Ω exist between No. 5 and No. 1-4 of the

motor-operated valve connector 5P (white)* or 6P (white)?)

Yes

Replace the

valve

No

Replace the

valve coil

7

Indoor unit’s

coil sensor

7-1

Are indoor unit’s coil sensors E1, E2, and E3 disconnected

from their measurement points? Check this by displaying the

indoor coil temperature on the outdoor unit.

Yes Repair

No 11-1

8

Cold/hot

water check

8-1

Is a correct cold/hot water (brine) fl ow volume being

maintained?

Yes

Maintain the

rated fl ow volume

No 8-2

8-2 Is the cold/hot water (brine) pump operating?

Yes 9-1

No Repair

GHPtroubleshooting.indbIV‒96GHPtroubleshooting.indbIV‒96 2012/11/2611:20:142012/11/2611:20:14

Loading...

Loading...